-

Industry Trends/Customer Challenges

Industry Trends/Customer ChallengesTraditional handwork: Requires clothing template, which is prone to inconsistent production standards, and it is difficult to recruit skilled workers, resulting in low production efficiency and high cost.

In addition, when using a traditional cutting machine to cut various fabrics, it is very inconvenient to modify the size, and it cannot meet the cutting of some complex graphics such as sharp corners, round holes, and lace encountered in the production process, and the rough incision causes rough edges, which seriously affects Garment quality.

Traditional manual and electric scissors are slow, difficult to nesting, inefficient and easy to waste materials. And the safety of employees cannot be guaranteed.

-

Advantages of GBOS Solutions

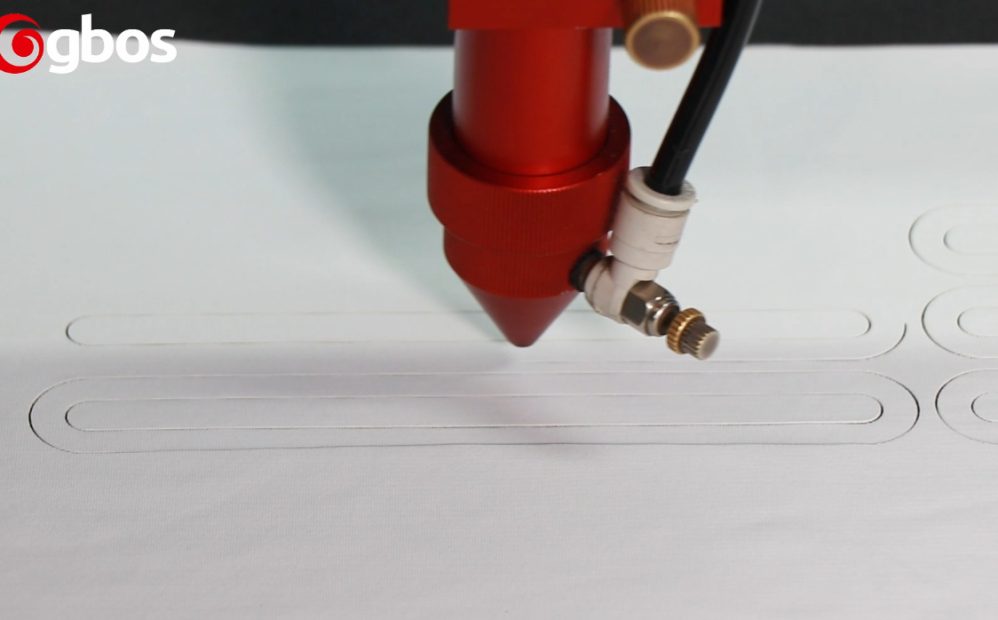

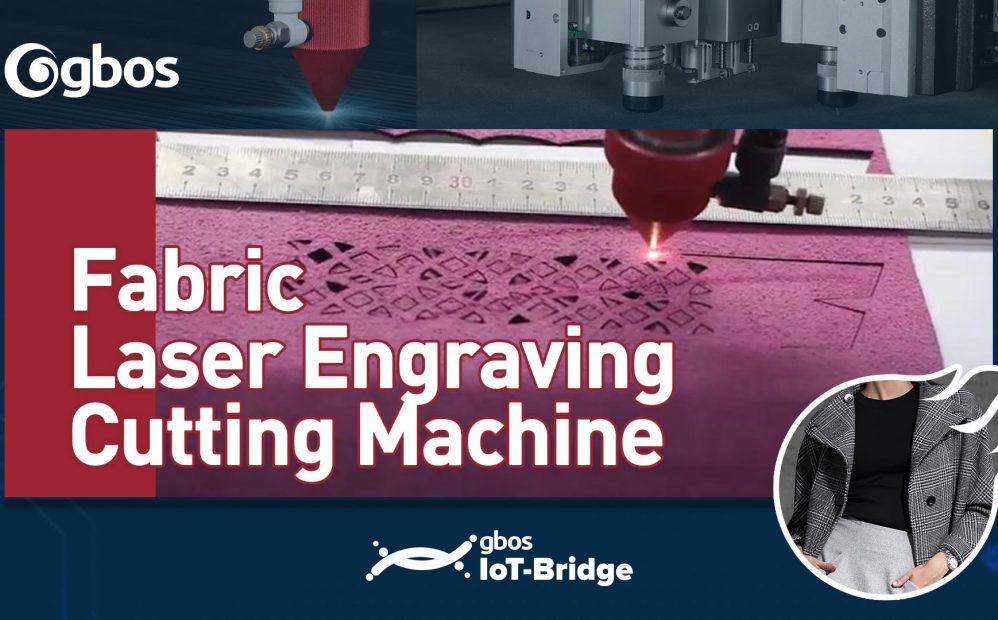

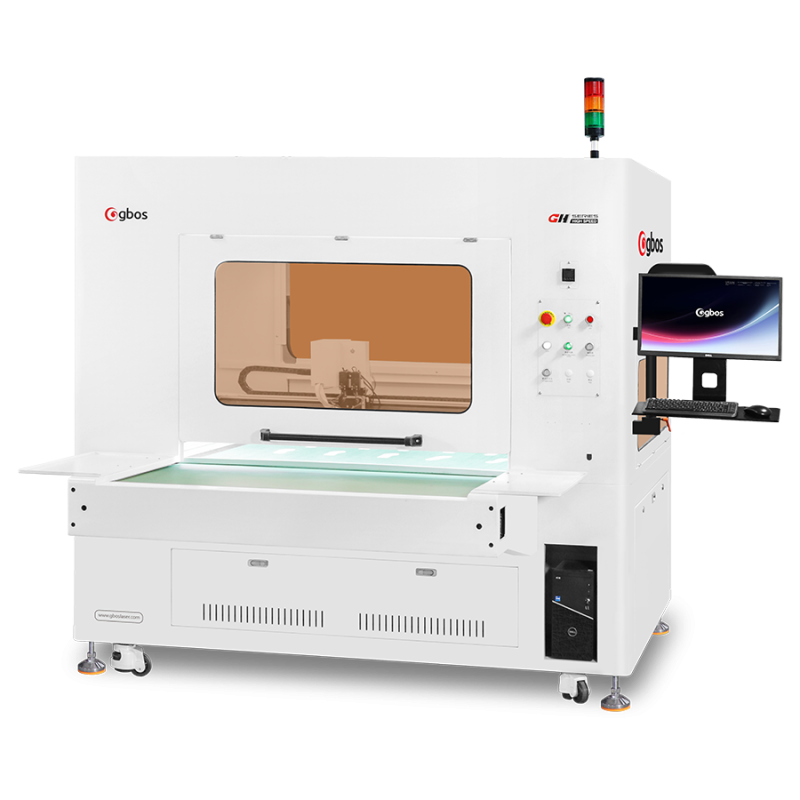

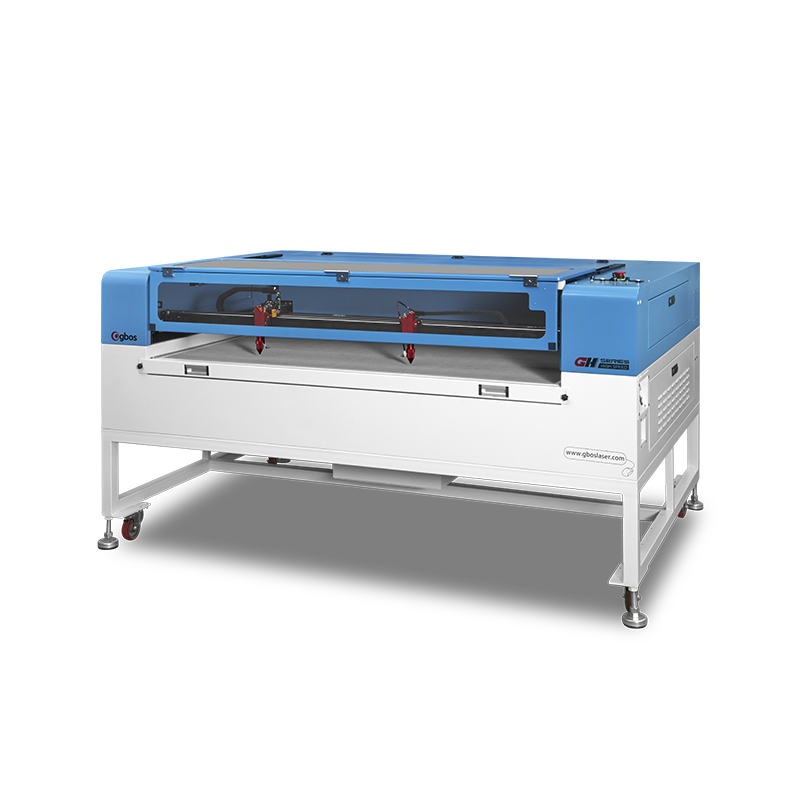

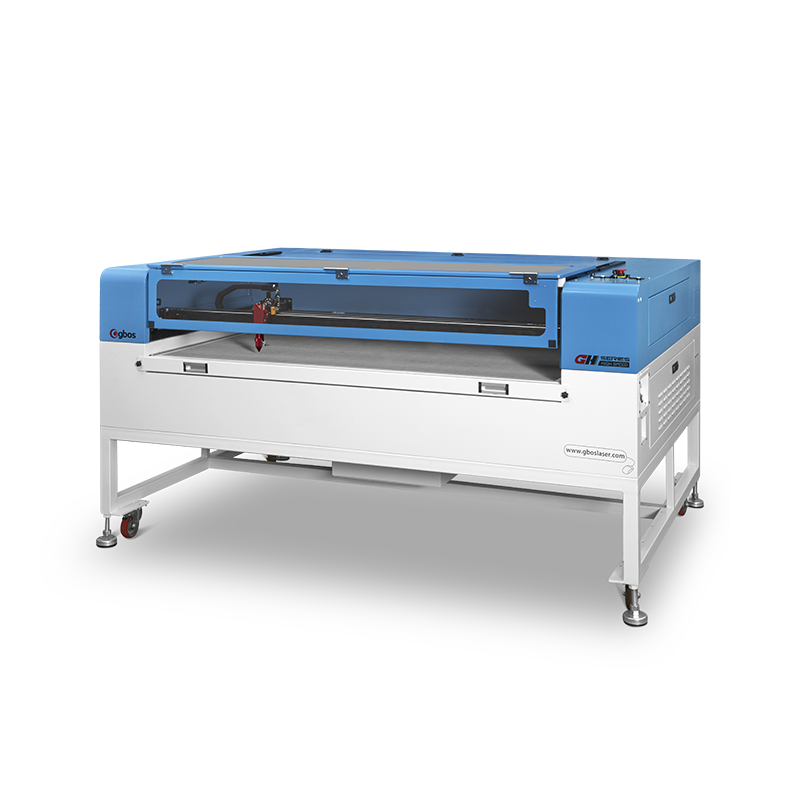

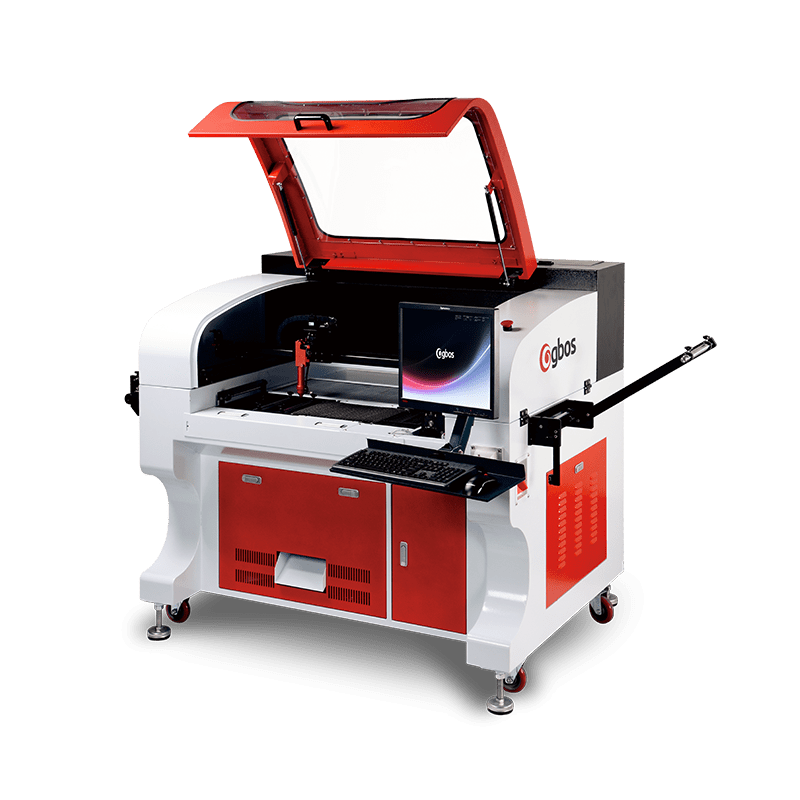

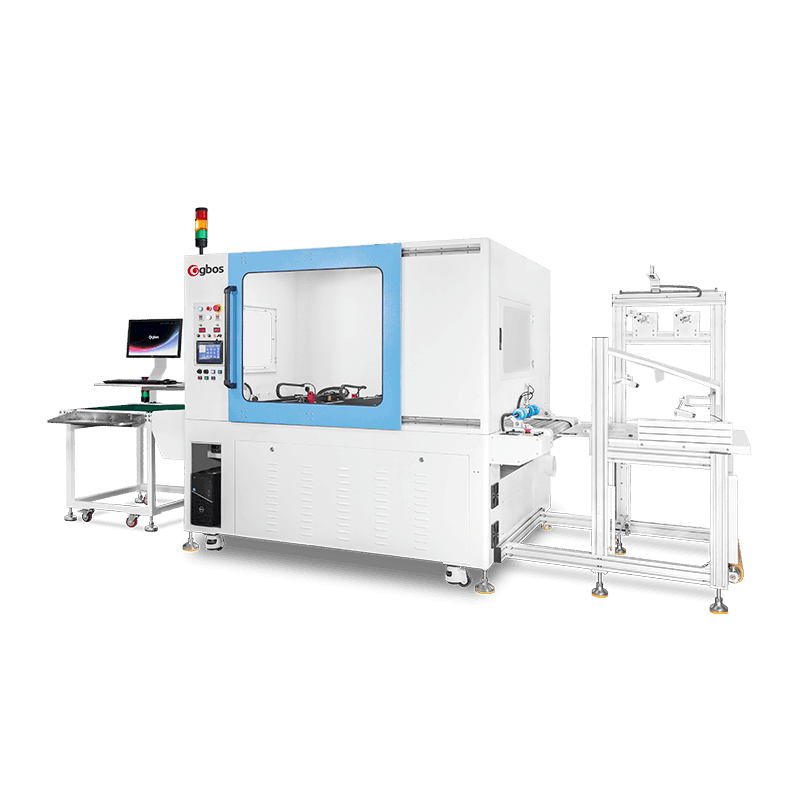

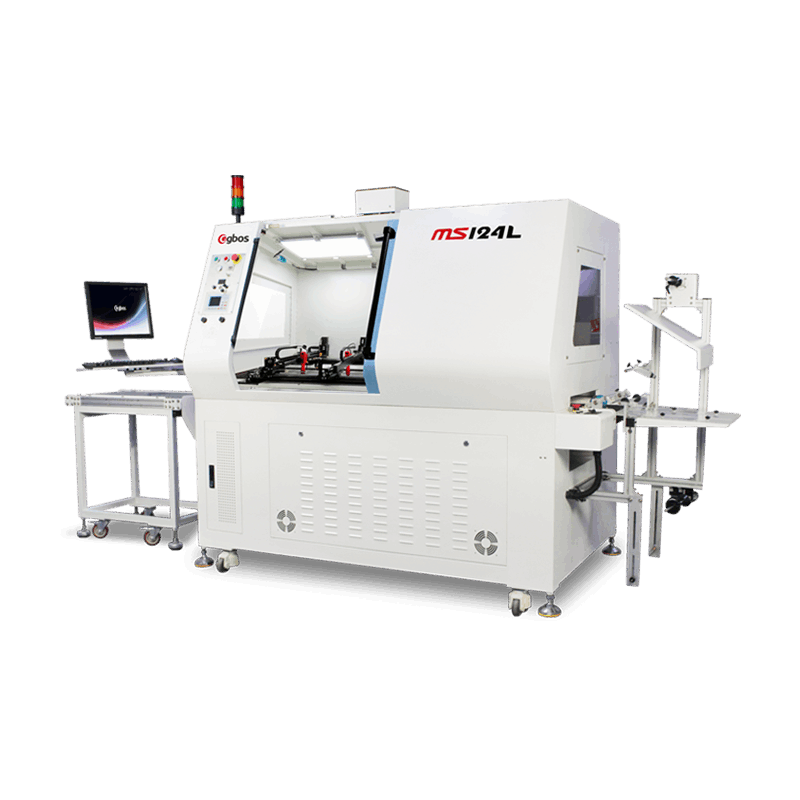

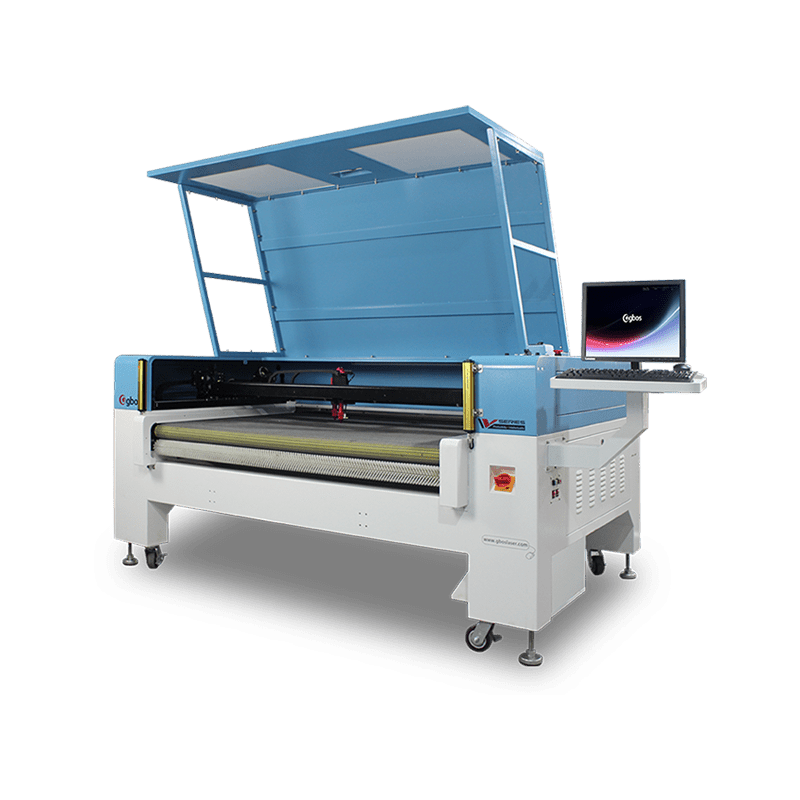

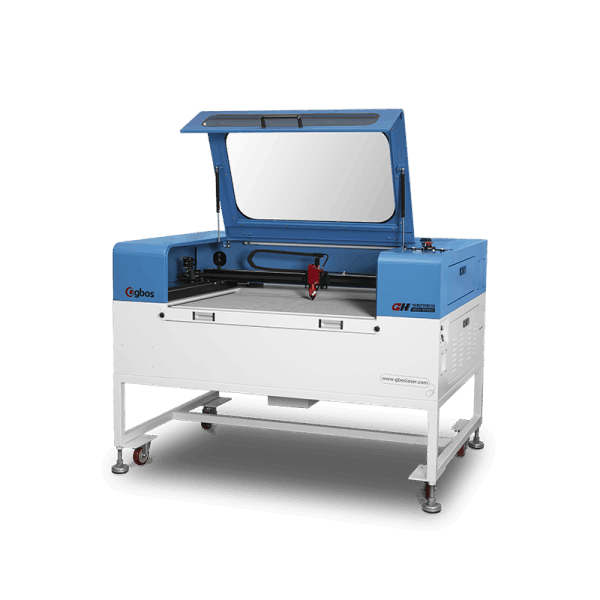

The laser cutting machine replaces the traditional stamping process, solves the enterprise's personalized, small batch, high-quality order requirements, and eliminates all costs for cutting dies and tools.

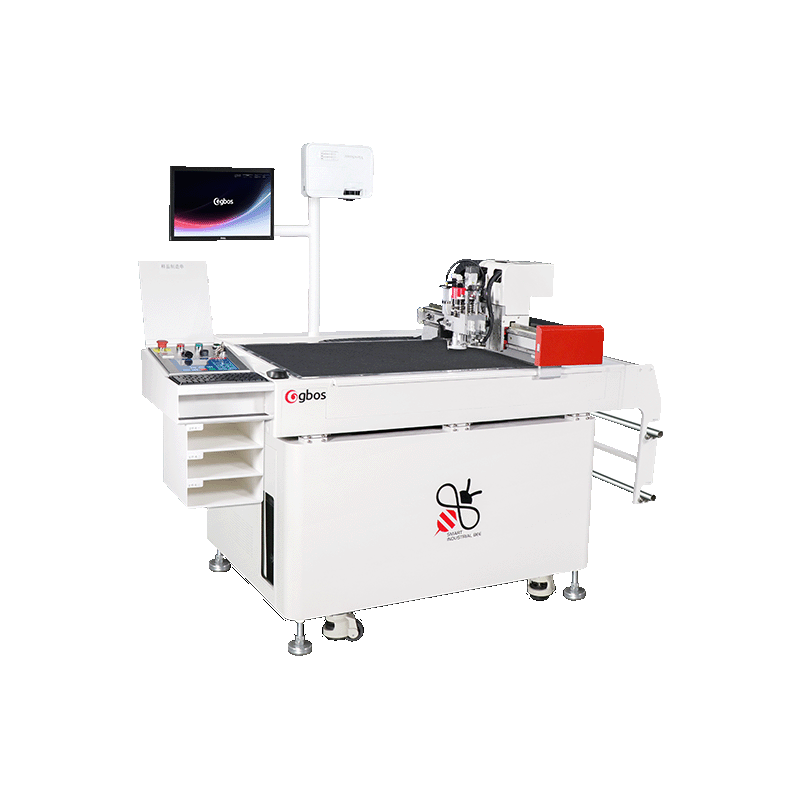

Not only solves the problem of difficult recruitment, but also improves production efficiency. It can help enterprise establish a unified production standard, to effectively arrange production plans and improve brand competitiveness.

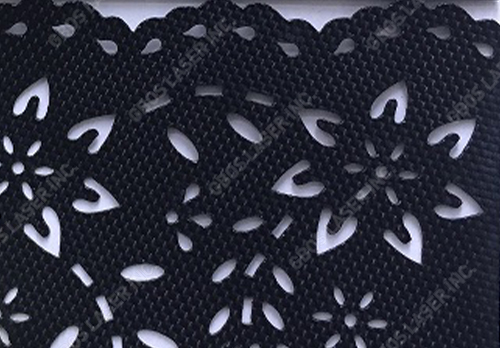

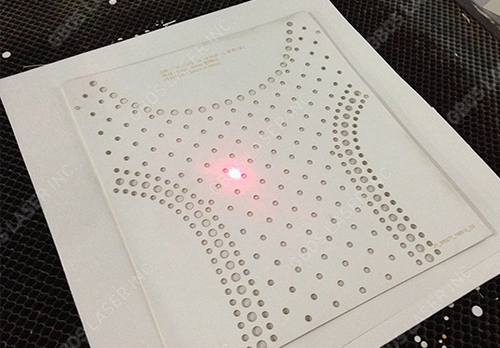

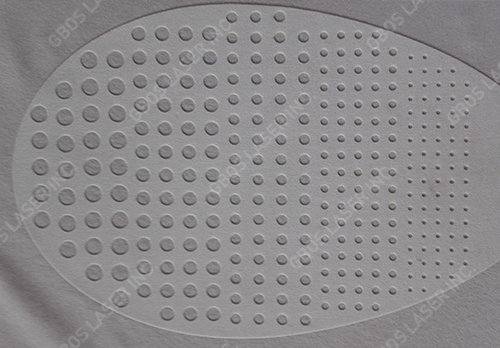

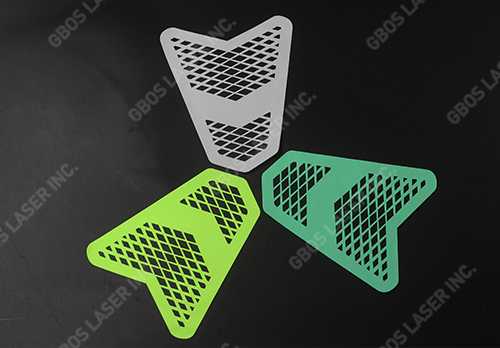

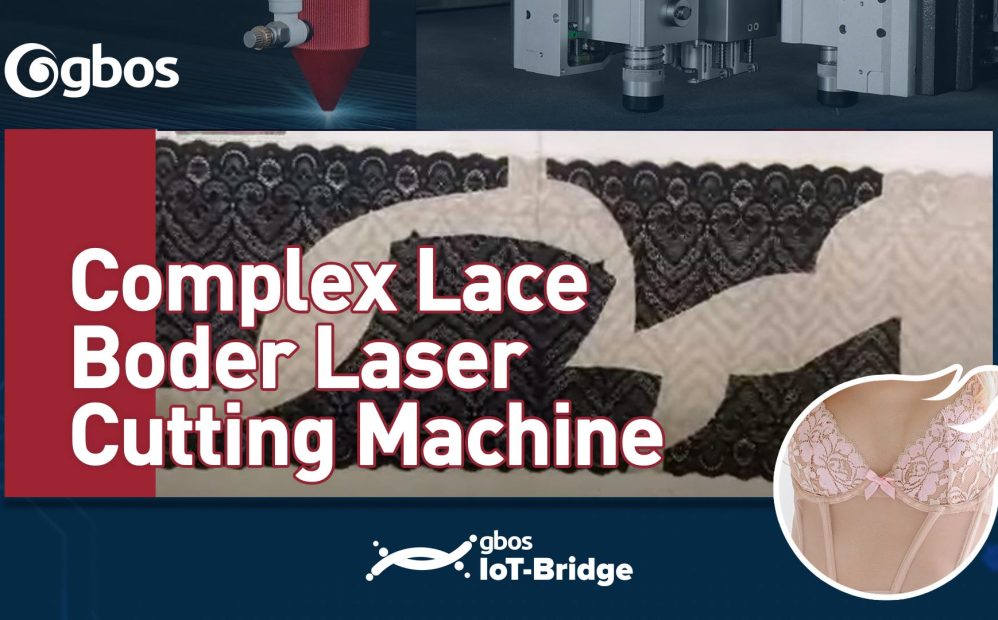

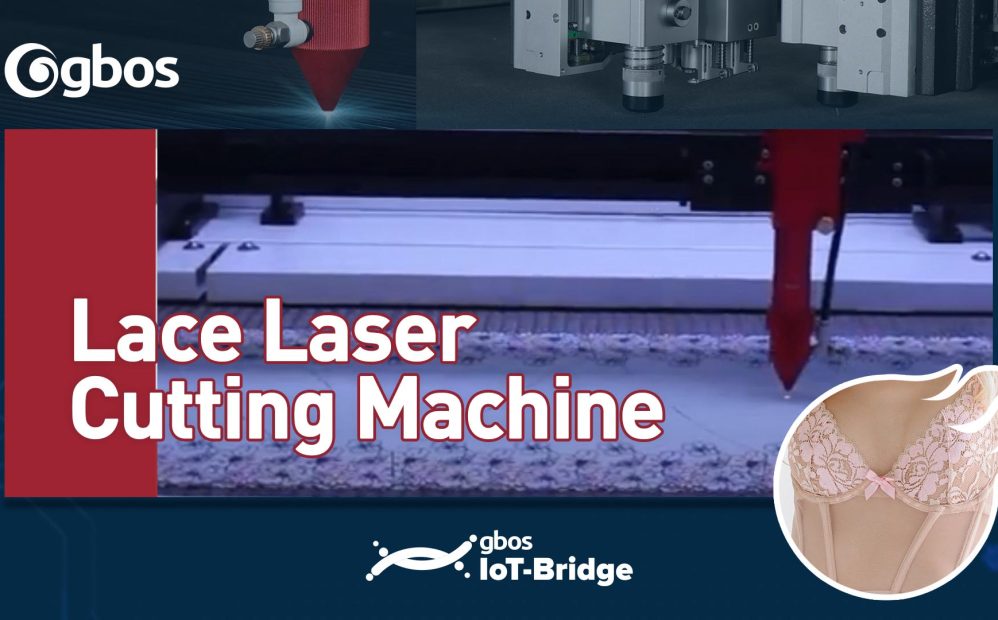

With the super powerful control system, Laser cutting no yellow edge, automatically close the edge without burr, no deformation, accurate size, solves the defects of complex geometric figures such as sharp corners, small round holes and lace that cannot be achieved by traditional cutting.

Superior nesting system greatly reduces material loss, mold storage and labor costs.

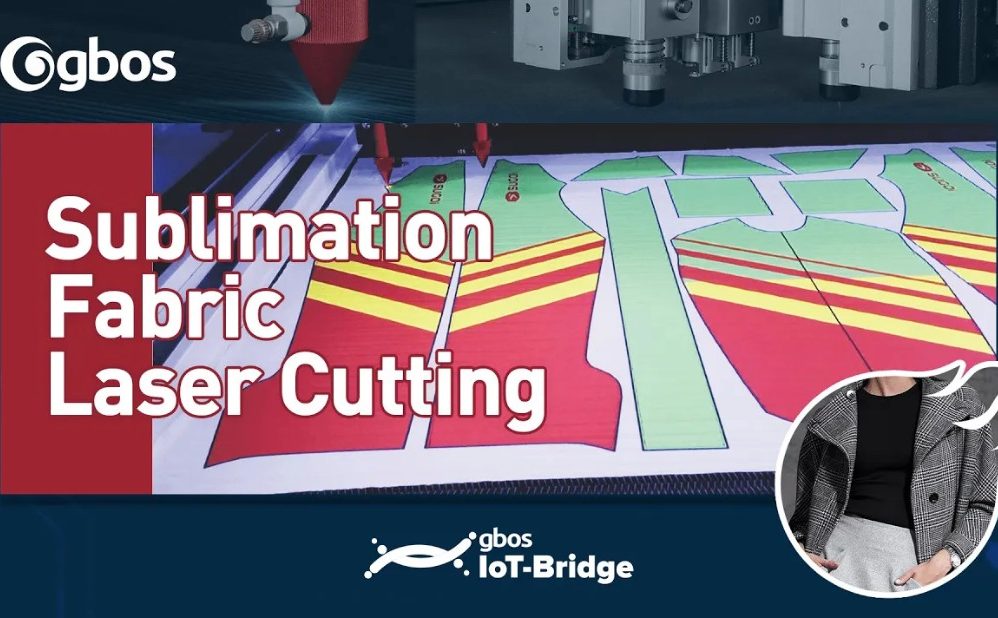

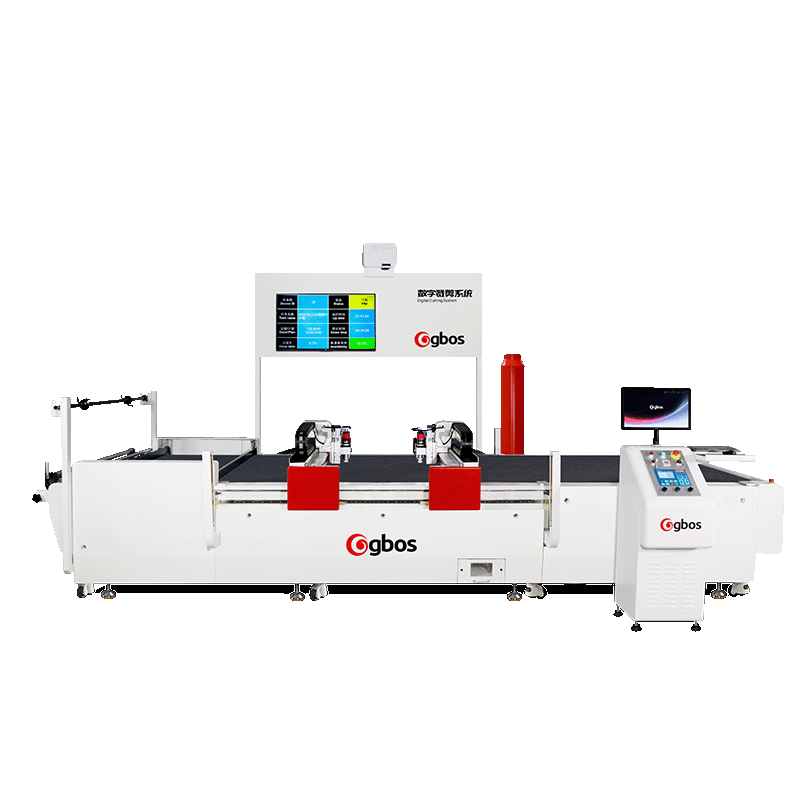

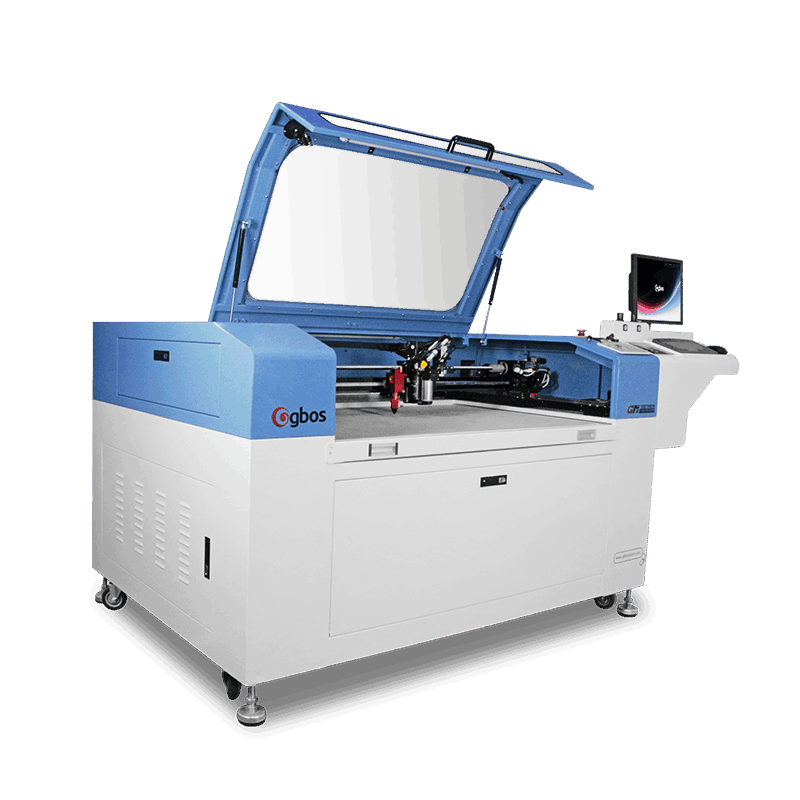

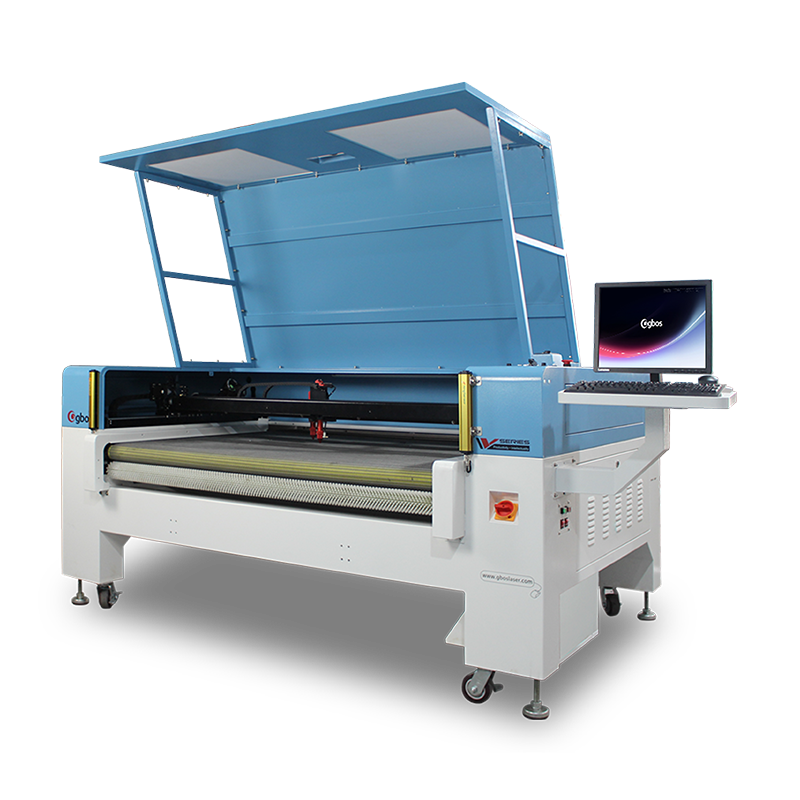

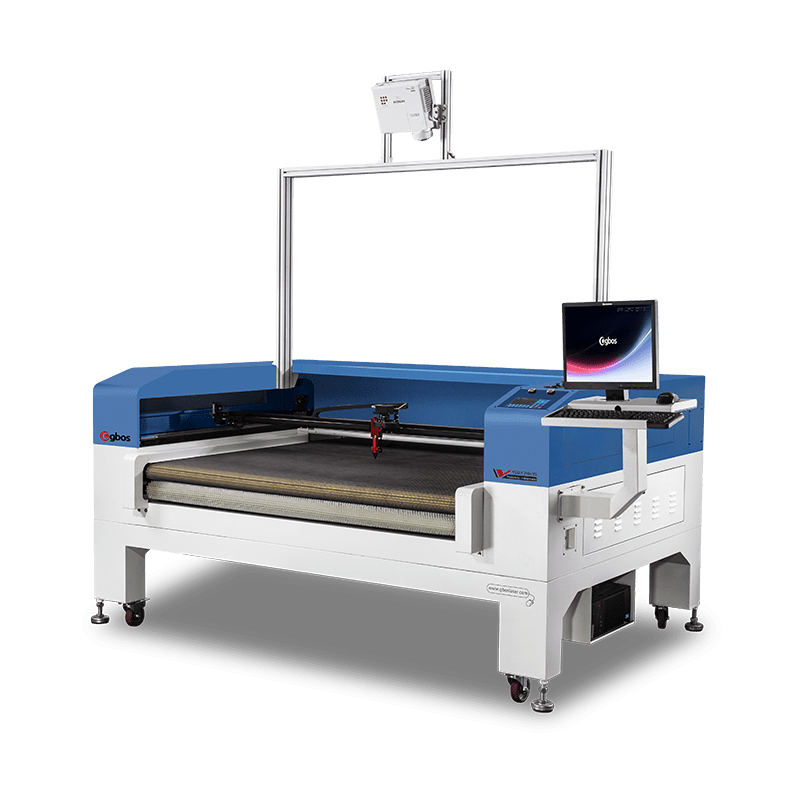

A variety of cutting solutions to match different cutting needs of customers, such as fixed worktable laser cutting machine for small size pattern normally cutting, auto feeding laser cutting machine for roll material, Super camera laser cutting machine for digital printing fabric, and so on.

The closed machine structure, ensures the safety of employees.

GBOS Laser machine is being widely used in the textile and garment industries due to its advantages of precise processing, fast processing, simple operation and high degree of automation, leading the fashion trend and promoting the rapid development of laser cutting technology in the garment industry.

- Laser Hollowing Fabric

- Laser Perforating Fabric

- Laser Marking Fabric

- Laser Engraving Fabric

- Laser Cutting Fabric

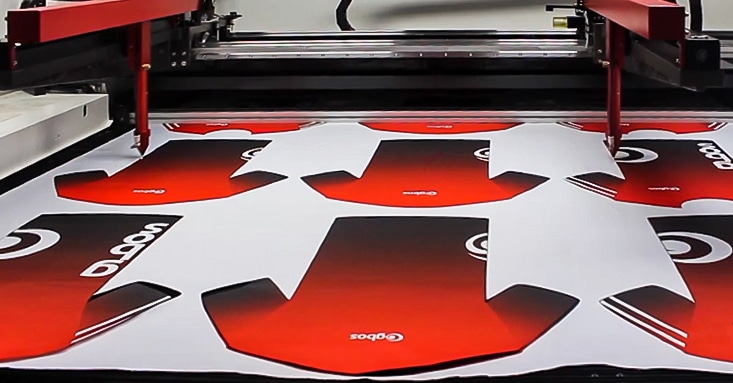

- Laser Cutting Sublimation Fabric

- Lace Border Laser Cutting Solution

- Button Laser Marking Solution

- Auto Line Marking for Fabric

-

V10SCCDV10SCCD Two Heads Async Automatic Grip Feeding Laser Cutting Machine With CameraMore Details

-

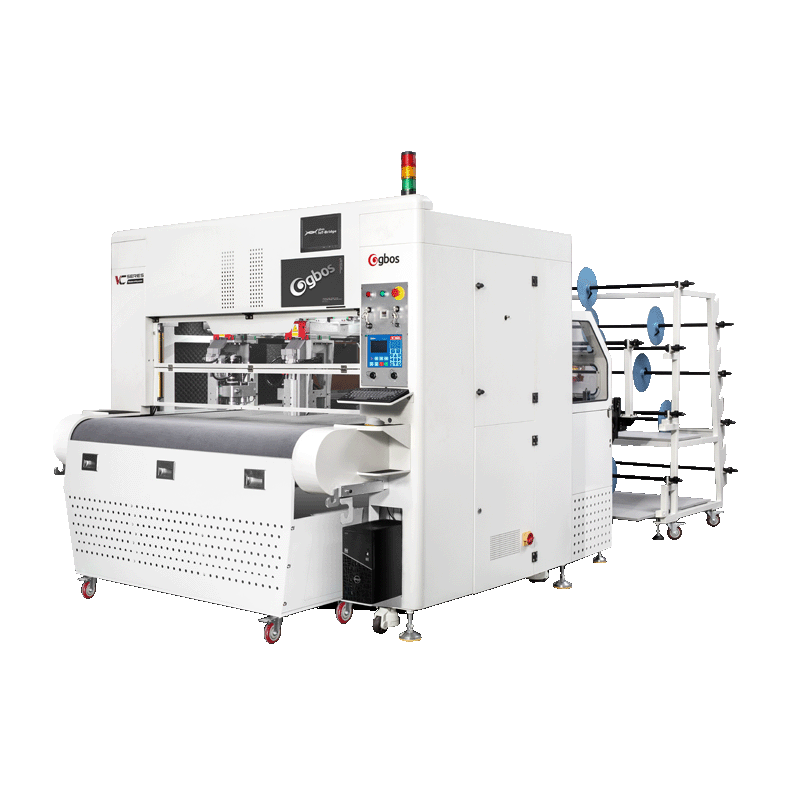

GN1081SCCD/5.0Dual AI Camera Laser Cutting Machine for Woven Printing Embroidery LableMore Details

-

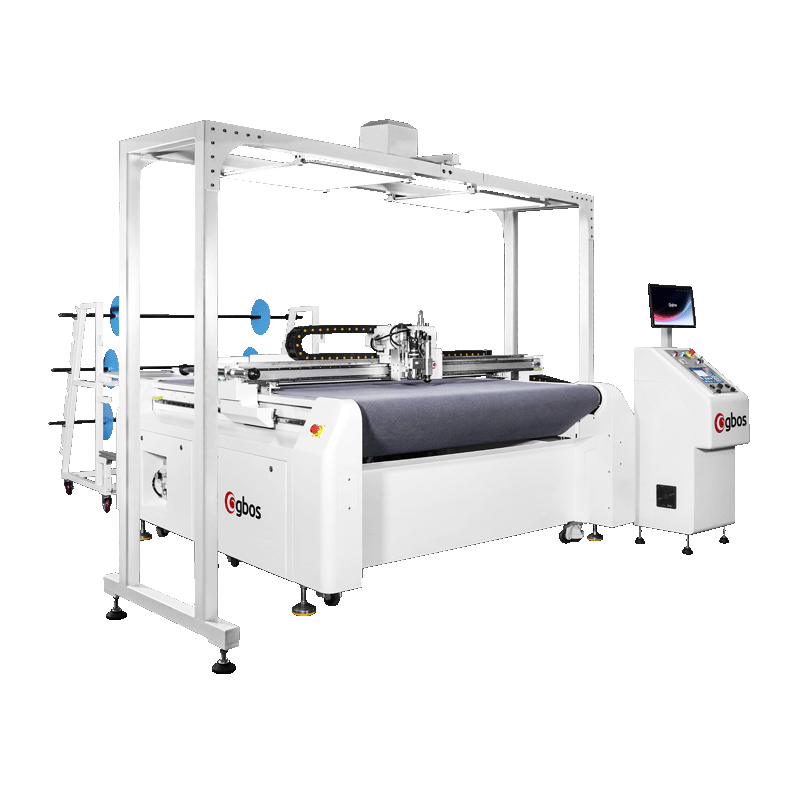

GH1610T-AT-CCDTwo-head Intelligent Auto Feeding Laser Cutting Machine With High-precision CameraMore Details

-

GH1812T-AT-SCCDTwo heads Intelligent Auto Feeding Laser Cutting Machine with Supper CameraMore Details

-

GH1812(TT)-AT-SCCDTwo Heads Asynchronous Intelligent Auto Feeding Laser Cutting Machine with Supper CameraMore Details

-

Jan 28,2026White and light-colored apparel remains a timeless choice in the fashion industry, valued for its clean look and versatility across work and casual settings, reflecting today’s preference for simple, quality living. Behind this “pure aesthetic,” however, lies a long-standing cutting challenge for manufacturers: preserving the fabric’s original beauty while ensuring production efficiency and precision. 01 White Fabric Cutting: A Seemingly Simple but Highly Demanding Challenge In the business world, real pain points are often hidden within needs that appear simple at first glance. Consumers expect white apparel to be clean and flawless, breathable and comfortable, and durable down to the finest details—but meeting all three expectations at once is a real challenge for manufacturers. Natural cotton, linen, and eco-friendly specialty fabrics offer excellent breathability and comfort, yet they are extremely difficult to cut. Traditional laser cutting generates high heat that can cause yellowing, darkening, or scorching along the edges—an almost “fatal flaw” for white fabrics. The result is either scrapped material or compromised brand reputation, driving up waste and production costs. At the same time, modern garment features such as seamless pockets and waterproof bonding tapes require highly precise cutting to ensure quality. Inaccurate cuts from traditional methods often lead...

-

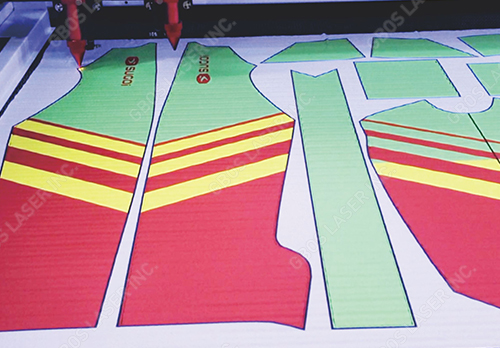

Nov 14,2025The 15th National Games recently kicked off in the Guangdong–Hong Kong–Macao Greater Bay Area, captivating the entire nation. On the field, athletes sprinted with full force, their fiery determination lighting up the arenas like blazing torches—igniting the public’s enthusiasm for sports in an instant. (Image Source: Shangguan News) As the nationwide passion for fitness continues to rise, sportswear that blends comfort, functionality, and fashionable design has become an essential companion for people on their athletic journeys. Behind every high-quality garment lies a quiet yet essential force: high-precision visual recognition cutting technology, which ensures superior quality through consistent and accurate cutting. 01 Under the Craze: Craftsmanship Pursuit & Manufacturing Challenges in Sportswear With the National Games driving public interest in health and fitness, consumers’ expectations for sportswear quality have been elevated. For classic patterns—such as stripes, checks, and digital prints—precise pattern alignment has become one of the most important indicators of garment quality. The alignment of shoulder seams, the continuity of side patterns, and the consistency of neckline and cuff textures all contribute directly to the garment’s final appearance. However, traditional cutting methods struggle to meet these exacting standards. ● Multi-layer stacked cutting often causes pattern displacement. ● Manual alignment is...

-

May 20,2025Recently, the topic of “PFAS in outdoor jackets affecting fertility” has sparked heated discussion, leaving many consumers deeply concerned. PART 1. Are Outdoor Jackets Toxic? Experts Say: Don’t Panic! According to Yang Longfeng, a science communication expert from the China Textile Engineering Society, the outer fabric of outdoor jackets often requires special coatings to achieve waterproof and breathable properties. These coatings may contain PFAS, including commonly used chemicals such as perfluorooctane sulfonate (PFOS) and perfluorooctanoic acid (PFOA), which are known to be harmful to both the environment and human health. This is one of the main reasons why the topic has triggered widespread public concern. However, there’s no need for excessive worry. Xia Wei, Deputy Director of the Institute of Environmental Medicine at the School of Public Health, Huazhong University of Science and Technology, pointed out that claims suggesting “outdoor jackets directly cause fertility issues” are exaggerated. Under normal usage conditions, outdoor jackets containing PFAS pose minimal direct health risks. The main concern lies in the potential for PFAS to enter the human body through hand-to-mouth contact or inhalation of dust after the coating begins to degrade or shed. By comparison, the intake of PFAS chemicals from everyday items such...

-

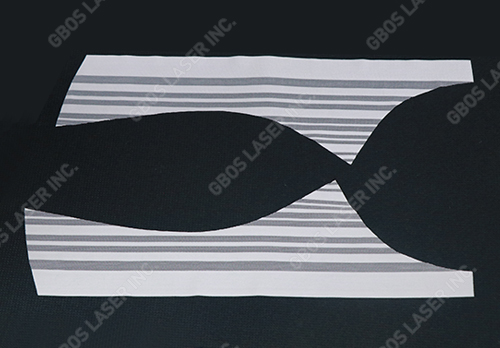

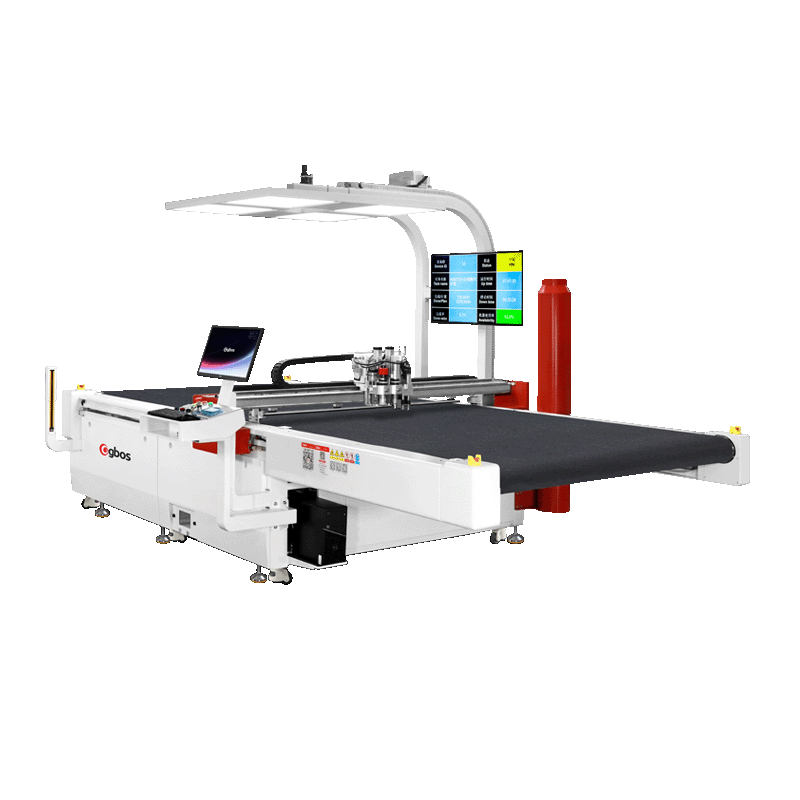

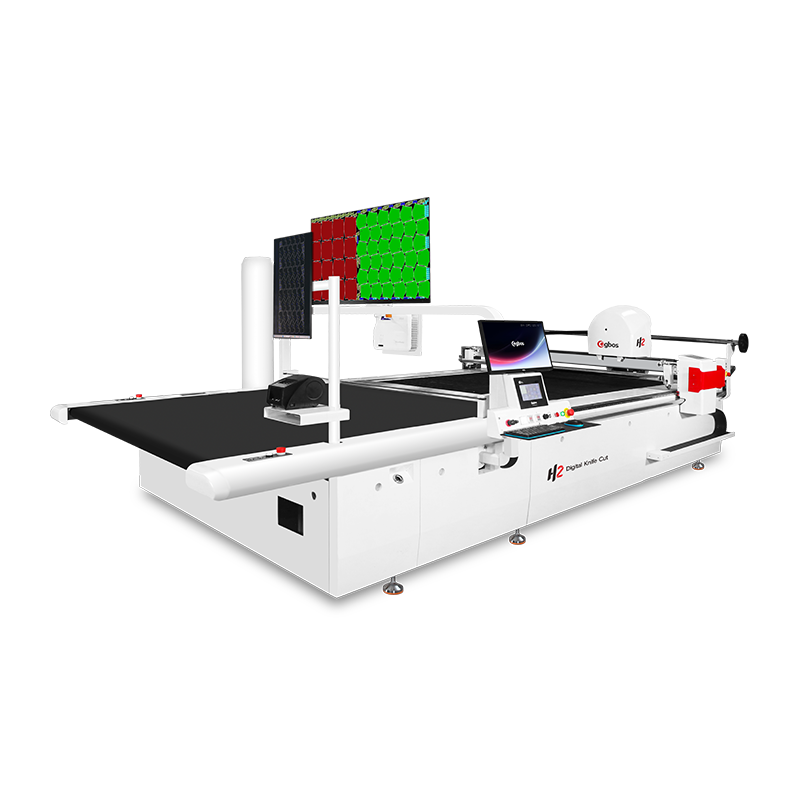

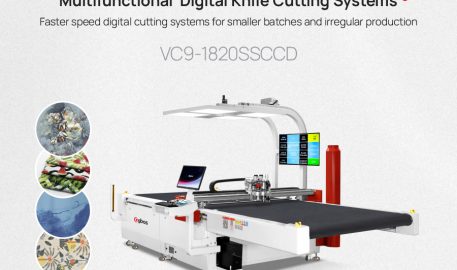

Apr 08,2025As the seasons shift, nature’s palette begins to turn once more—the air grows milder, life flourishes, and the world of fashion steps into the vibrant wave of seasonal change. In this dynamic and fast-paced moment, the apparel industry is racing to launch its latest collections. Amid the complexity and variety of seasonal garment production, a cutting machine that can meet these demands with precision has undoubtedly become the center of attention. Developed by GBOS, the multifunctional single-layer digital knife cutting system VC9-1820SSCCD is a faster digital cutting solution designed for small-batch and irregular production. This machine brings unprecedented convenience and efficiency to your garment manufacturing process. 01 Precision in plaids and stripe alignment — showcasing the beauty of stripes With the arrival of spring, striped shirts and T-shirts have become wardrobe favorites. However, in the production of striped garments, achieving precise pattern and stripe alignment has long been a challenge for apparel manufacturers. Equipped with an AI VisionScan system, the VC9-1820SSCCD accurately detects stripe direction and spacing, enabling precise pattern and stripe alignment during cutting. Whether it’s fine, delicate pinstripes or bold, wide stripes, the AI VisionScan system ensures that every cut piece aligns perfectly. This attention to detail enhances...

-

Mar 25,2025On March 22, the NIKE MM WAVE 1 TEAM from global sports giant NIKE visited GBOS. Both parties engaged in in-depth discussions on one-stop digital cutting solutions for the apparel industry and reached a consensus on collaborating to establish an AI digital cutting center and build an open industrial ecosystem. NIKE’s MM WAVE 1 TEAM consists of globally renowned manufacturing factories, playing a key role in ensuring high-quality, high-efficiency production and innovation for NIKE products. It represents the industry’s top production standards. 01 Deep Integration of Concepts: Exploring Industry Trends Together During the exchange meeting, the MM WAVE 1 TEAM showcased NIKE’s top-level supply chain design approach, engaging in an in-depth discussion with GBOS on its intelligent cutting solutions, from technology matrix analysis to flexible production, process innovation, AI and digitalization, and industrial ecosystem applications. GBOS’s green intelligent manufacturing technology aligns with NIKE’s “Zero Carbon Manufacturing 2030” strategy, creating a strong technical synergy. Both parties also had a dynamic and productive discussion on how to meet consumers’ growing demands for functionality, sustainability, and fashion in apparel. 02 Exploring the Innovation Center: Experiencing the Power of Technology [Process Innovation] During the technology demonstration, the NIKE team conducted an in-depth evaluation of...

-

Feb 15,2025As of February 10, Ne Zha: The Devil Child Rages at the Sea (hereinafter referred to as Ne Zha 2) has surpassed 8 billion yuan at the box office, claiming the top spot in China’s film history. Alongside its box office success, co-branded merchandise is selling out at an astonishing rate—numerous companies have launched collaborative products, crowdfunding for various original merchandise has exceeded tens of millions, co-branded T-shirts and blind boxes are selling out instantly, and resale prices have doubled. In short, Ne Zha-themed products are in overwhelming demand. Behind this Ne Zha craze lies the immense potential of the IP product economy. Today, the influence of IP has long transcended film, literature, and other creative works, extending into various consumer sectors. Products built around popular IPs—ranging from toys and stationery to apparel and footwear—often achieve remarkable market success, driven by fans’ passion and deep connection to the IP. According to relevant data, the global IP licensing market continues to expand, with growing consumer demand for IP-based products. This undoubtedly presents vast market opportunities for the development of the IP product economy. For peripheral product manufacturers, this is both an opportunity and a challenge. The key focus is how to...

-

Dec 31,2024In the vast world of fashion, colors are as variegated as the palette, and white and light-colored clothing, like a touch of fresh wind, quietly captured the hearts of many users. They are a kind of self-evident elegance, interpreting the aesthetic concept of simplicity and uncomplicated. People prefer these colors, perhaps because they can be cleverly blended with a variety of occasions and styles, like a blank canvas, allowing personality and creativity free to play. White and light colors, but also comes with a kind of purification of the soul, so that people in the busy and noisy find a trace of peace and calm, as if it is the purest language of nature, gently telling the story about the beauty. 01. Material challenges, technical bottlenecks However,Behind this pure beauty,lies a challenge that garment manufacturers are not aware of. Especially when cotton, linen, or more environmentally friendly special materials are chosen, these materials are favored for their natural, breathable properties, but the cutting process poses a challenge for manufacturers. Traditional cutting methods are often difficult to manage, especially laser cutting machine, if the technology is not advanced enough, it is easy to produce yellowed edges, black, and even burnt edges...

-

Dec 06,2024Sportswear is an unprecedented new fashion, deeply integrated into our daily commuting life. Whether it is sweating on the field, fierce confrontation posture, or the streets and alleys to lead the trend of wearing show, sportswear have won the majority of consumers a wide range of favor and deep love. 01 The ultimate in craftsmanship and materials In sports events, the passion of the fans is not only focused on the players, but also poured into the team uniforms. Team uniforms created by top brands transcend the boundaries of clothing and become the “holy grail” in the hearts of fans, carrying admiration and love. Wearing the same model, fans seem to be transformed into warriors, and idol side by side to fight, share the passion and glory. However, behind the same clothing of these teams lies the ultimate pursuit of craftsmanship and materials. Manufacturers who want to take orders from these brands must have profound professional strength and exquisite production skills. The cutting of fabrics for sportswear is one of the key tests of a manufacturer’s skills. 02 Innovation in cutting technology: “single layer cutting” With the continuous innovation and upgrading of brand design, the cutting requirements for sportswear fabrics...

-

Dec 02,2024In the steady development process of GBOS, the collision of ideas and the exchange of experience has always been a strong driving force for our continuous progress. September 10,2024. the morning sun gently embraced the earth, guests from all over the world stepped into GBOS Dongguan headquarters operations center venue with a brisk pace. Under the enthusiastic and professional guidance of the staff, the guests moved from the sign-in wall to the main venue in an orderly manner, and a seminar on [Smart Renewal of Classics – Creating Changes for the Future], the 2024 GBOS Seminar on Innovative Processes in Garment Accessories Industry and Technical Exchange Meeting, was formally kicked off! Continuing the Classic – Creating the Future This exchange meeting is divided into the morning session and afternoon session, chaired by the clothing accessories industry manager Jiang manager, chairman of the board of directors Mr. Liu Wu new product release. First of all, Mr. Liu Wu sent a warm welcome and sincere thanks to all the elites in the garment accessories industry who attended the exchange meeting! And introduced the significance of this exchange meeting to all the industry elites in detail. Mr. Liu said, in the process of...

-

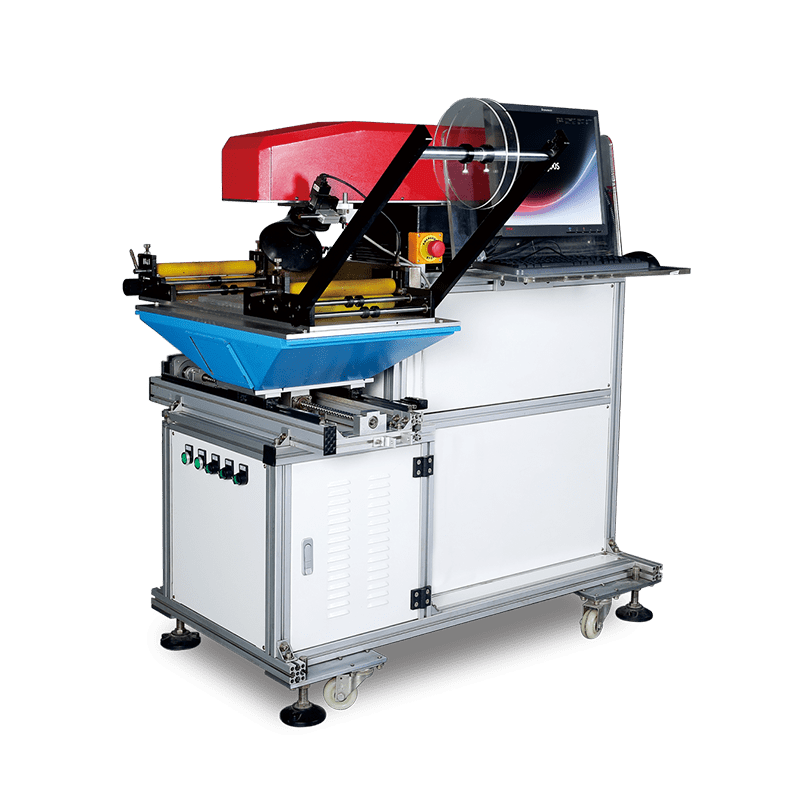

Mar 30,2023Hey, Let’s explore garment & accessories process application solutions now! Machines & Applications in ITMA Exhibition. Underwear art-craft. 1) 2021 Newest PUR glue dispensing for seamless technology. How to get faster efficiency in the seamless artcraft? GN1280-DP-SG, PUR dispensing + laser cutting all in one! Another seamless underwear solution: VC9-1612SCCD-DP, PUR dispensing + digital knife cutting all in one! 2) UV3A, tag-less label laser marking machine. A solution without ink for care label, achieve environmental protection and labels permanent. 2. Show you 3 kinds of smart label cutting solutions. 1) GN1081SSCD 5.0, Double camera VisionScan sheet labels laser cutting machine. Large size automatic extraction with VisionScan system; Automatic extraction of contour; Automatic extraction of contour. Let you achieve precise cutting with large area! 2) FB02CCD, Roll ribbon labels and sheet labels laser cutting. For roll to roll ribbon labels, it will cut off and feeding automatically, don’t need to pull by manual. 3) FB07CCD, Automatic soldering iron edge burning machine for embroidery patch. Cover a small area, and can instead of traditional manual cutting, 1 person can operate 10 units. 3. Two solutions for the digital/sublimation printed fabric cutting: 1) Laser cutting with high precision camera. 2) Knife cutting with high precision camera, Can you imagine how fast it...

-

Feb 08,2023Cutting department plays very important role in any apparel/garment industry. To make a complete garment, cutting is necessary. Without cutting process to make a cloth is out of dream. It is also extremely important to use the right cutting tools in the garment/fabric/apparel cutting process — If you want to do a good job, you must first use a good tool. How do you choose the best tool for the job among many others? Here you two best fabric cutting ways, they provide endless customization opportunities. 1. Fabric laser cutting machine: ① A/Double/Four heads optional, precisely control of your capacity and delivery times. ② A variety of processes can be achieved: cutting, hollowing, perforation, engraving, sublimation fabric and other pattern with logo, etc. ③ Laser process without contact-free, no deformation of the flexible fabric. ④ Automation and customization benefits: Laser cutting can easily be repeated and is easy to automate. ⑤ Smooth cutting edges. Advantage of laser cutting in fabric manufacturing is that it creates smooth edges with no yellow no burns. 2. Fully Automatic / Computerized cutting machine——Oscillating knife digital cutter for fabric cutting. ① No tooling costs. Fabric oscillating knife digital cutter without any tools. Hence there is no need for tool storage,...

-

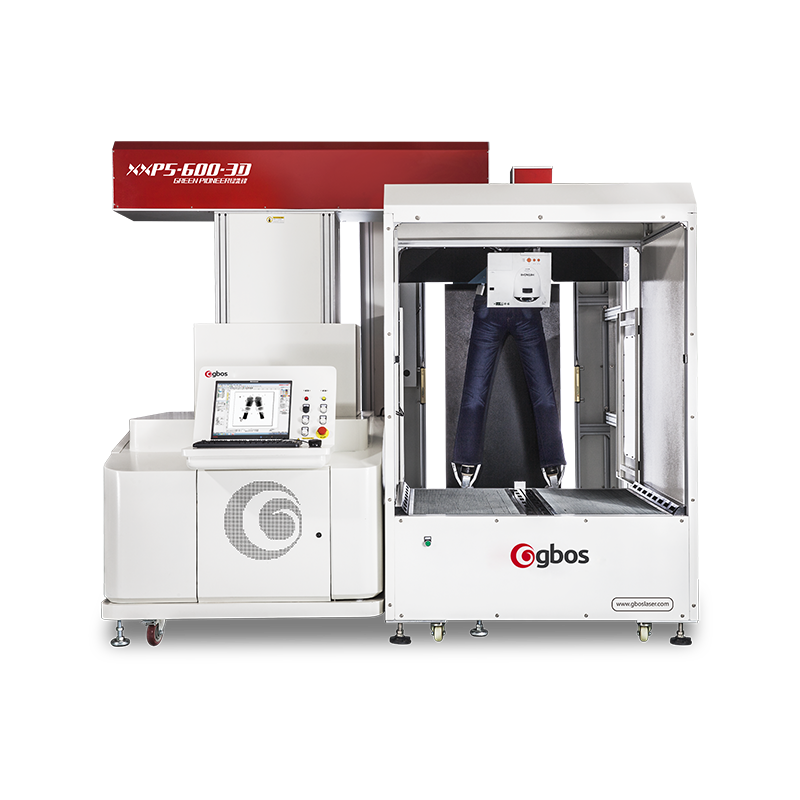

Oct 13,2020As we all known, laser marking machine can be applied in all kinds of industry, like: garment, garment accessories, footwear, gifts, packaging, sign, and other non-metal industry. Also, can used for metal industry… For GBOS, We mainly focused on researching the garment and footwear industry for 16 years. GBOS R & D team constantly research according to the market demands. Especially the machine: XXP3-180. We call it “GBOS King Laser Marking Machine”. Maybe you have some question in model number XXP3, “3” means the third generation, After the first and second generation of technology, market experience, and the change of customers’ needs. We have developed our third generation laser marking machine, which are more accurate than the previous one. What’s more, it intergrated for cutting & marking & engraving & hollwing with one machine in garment and shoe industry. It’s a laser processing with adopting to non-contact, It will not be harmful to the fabric, So that we can manufacture more comfortable apparel, and apparel with no burrts,no yellow,etc… Here are some videos about XXP3 Contact us, GBOS not only be limited to garment and footwear industry, You can find we also involve other industry from videos~

-

Jan 27,2015January 10, 2015 saw the most advanced four domestic laser application devices (XXP3S, XXP5-300, All new B series, M2) as successfully promoted by GBOS Laser after 4 years of R&D and trial for six months. Having passed all kinds of strict standards both at home and abroad, these four models are key products in the domestic laser intelligent application field. In particular, some models fill the gap of lots of patents in this research field. They truly stand for “Made in China” and show the sophistication of modern industrial design completely, ranging from their body curve and appearance, the core components to structures inside the devices and their perfect application. Unpiloted intelligent operation The machine XXP3S laser intelligent continuous marking and hollowing, which is deemed as airplane carrier in this field. Applied industries: Garment, leather products, craft gift, packaging and ads. Applied materials: Batch hollowing and carving of twist leather, cloth and flexible fabric. It is the only laser-based full-automatic feed system for volume production in China, with the advantages such as saving labor force, materials and time and high continuous working efficiency. It can complete many procedures (piercing, carving, incision and lineation) at one time. The dual workbenches can...

![[Intelligent renewal of the classic・Creative change in the future] Locking the innovative chapter of garment sccessories material [Intelligent renewal of the classic・Creative change in the future] Locking the innovative chapter of garment sccessories material](https://www.gboslaser.com/wp-content/uploads/2024/12/2024120210532526ae7-457x270.jpg)

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: