-

Industry Trends/Customer Challenges

Industry Trends/Customer ChallengesMassive Mold Production: Continuous molding for different products.

Nowaways, fast fashion makes orders come in small to medium batches, which requires shorter lead time & more delicate crafts.

Industries like car interiors, helmets, suitcase industries & smart wearable industry extremely require an intelligent & automatic cutting solution.

In the car interiors, helmets, suitcase industries, etc., it's used to cut by milling cutters. However, the edges aren't cut smoothly.

In addition, the loud cutting noise, lots of dust & debris make it humful to the workers' health and lead to environment.

For flexible materials used in smart wearable industry, like VR/AR headsets, it's used to cut by die cutters.

However, die cutters are not available for three-dimensional or curved materials' cutting, thus manual cutting is used.

Due to ununified cutting standards, high labor costs & low efficiency, manual cutting.

-

Advantages of GBOS Solutions

Advantages of GBOS SolutionsNo Mold: Die-less 3D five axis laser cutting & trimming for shaped materials, no mold cost, propelling businesses toward automation and intelligence.

Customized: Provide customized solutions based on customers' demand.

Addressing Various Issues: Improving production processes is crucial to address issues such as high manual cutting defect rates, low capacity, high labor costs, and expensive tooling costs.

High Scalability: 360° rotation at will; Dual-table design, loading and unloading synchronously, improving efficiency and production output.

- VR Headset Laser Cutting Solution

- Shaped Hole Laser Cutting Solution

- Sports Helmet Laser Cutting Solution

- Shpaed Door Trim Laser Cutting Solution

- Spherical Lampshade Laser Cutting Solution

- Injection Gate Laser Cutting Solution

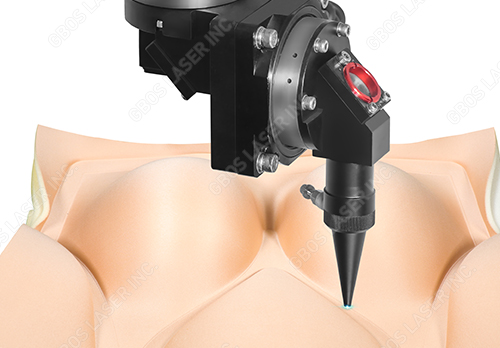

- 3D Bra Laser Cutting Solution

-

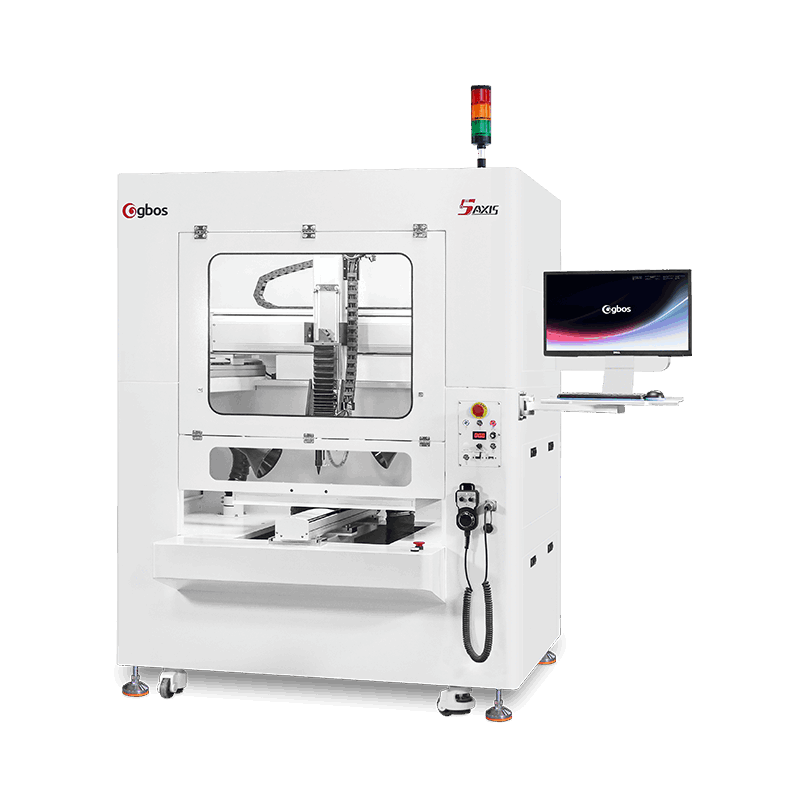

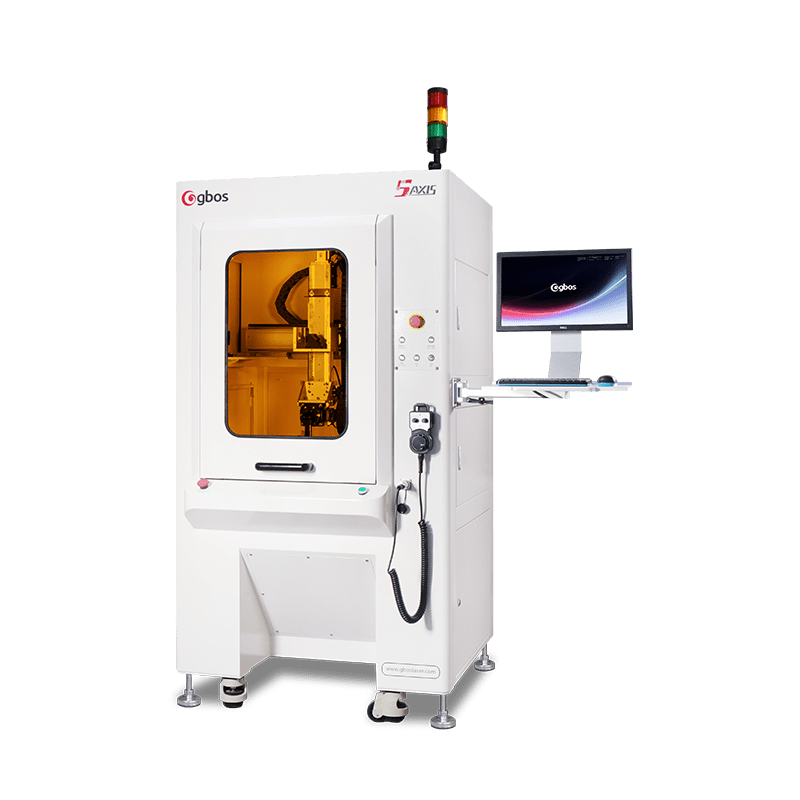

GN502-3D-EPGN502-3D-EP Five-axis Intelligent CO2 Laser Cutting Machine With Dual Working Tables.More Details

-

Aug 08,2024Under the wave of technological advancements, the release of the Apple Vision Pro has struck like a bombshell, not only redefining the boundaries of “spatial computing” but also heralding a new chapter in the integration of the digital and physical worlds. Although Vision Pro has captivated global attention with its unprecedented immersive experience and innovative design, on a deeper level, it has sparked endless imaginations about the manufacturing process innovations for VR smart wearable devices. From Concept to Reality: Technological Innovation Leading Industry Leap The advent of Vision Pro is not just a bold attempt by Apple to explore the metaverse but also a profound revelation to the entire VR/AR industry—how to seamlessly integrate the infinite imagination of the digital world into real life through technological innovation. Under this trend, VR smart wearable devices, as a bridge connecting the two worlds, face increasing complexity and challenges in their manufacturing processes. Five-Axis Laser Cutting Machine: Unlocking a New Chapter in Curved Surface Cutting Facing the increasingly complex shape designs of VR wearable devices, traditional processing methods can no longer meet the high-precision and high-efficiency production demands. At this critical moment, Guangboshi, with a forward-looking perspective, has launched the GN602-3D-EP three-dimensional five-axis...

-

Nov 01,2023In recent years, the introduction of the “one helmet, one belt” policy has brought significant changes to the domestic electric vehicle helmet regulations. This has not only enhanced end-users’ understanding of the importance of helmets in travel safety, but also spawned the rapid development of the helmet industry. Against this backdrop, GBOS has iterated a one-stop intelligent solution for the wearable industry with superior technical strength and advanced manufacturing concepts, aiming to meet the all-round needs of consumers for helmet safety, comfort and personalization. GBOS One-stop Smart Wearable Solution For cutting the support inside the helmet, GBOS KC1625TT-SD Digital Cutting Sharpener shows great strength. According to different material types and cutting needs, it can choose to match different modular tools to meet diversified cutting needs and open up diversified material selection space. In the face of the helmet’s outer parts production, often need to use the mold to carry out the helmet injection molding parts cutting. However, different styles require different molds, which undoubtedly increases the cost and creates a management burden. The GN602-3D-EP solves this problem. This 3D 5-axis laser cutting machine is suitable for cutting all kinds of shaped products, which can replace the traditional punching...

-

Feb 08,20232015, Launch three-axis laser cutting machine. 2017, Launch four-axis laser cutting machine. 2019, Launch five-axis laser cutting machine. (and delivery the first 3D five-axis laser cutting machine in the same year) The breakthrough of GBOS’s 3D five-axis technology not only represents a better process application for users, but also brings undeniable power to promote the development of the industry. As an innovative product applied to the non-metallic field, it has shown many excellent advantages and highlights in helping various industries to transform and upgrade. In the process of processing, no moulds are required, thus reducing the cost of mould opening and mould management; secondly, the application of trimming and cutting holes for various shaped and 3D curved products greatly improves production efficiency. As the level of intelligent continues to rise, the 3D complex surface laser cutting process has also continued to make breakthroughs and is now successfully used in small/large batch manufacturing in industries such as automotive, aerospace, lighting, luggage and lingerie. It enables the trimming and punching of shaped edges and holes for automotive interior injection moulded parts, car lamp spouts and luggage blister parts, greatly increasing the efficiency of the production process and producing products with smooth and...

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: