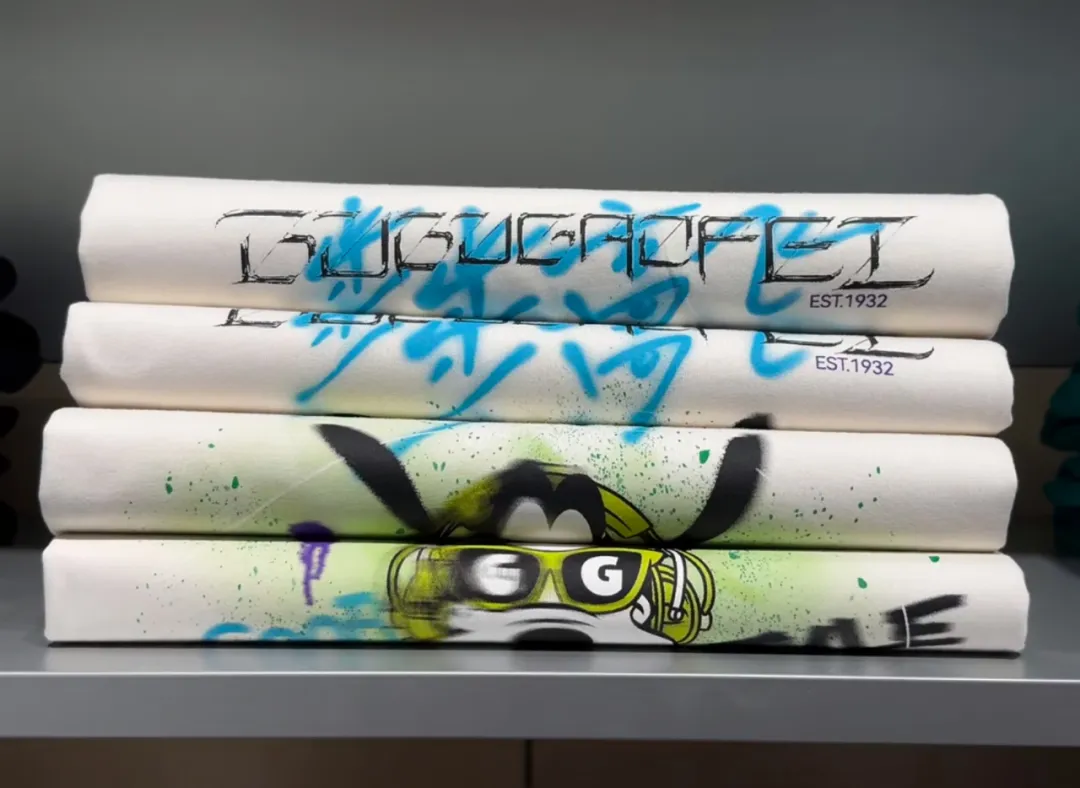

In the vast world of fashion, colors are as variegated as the palette, and white and light-colored clothing, like a touch of fresh wind, quietly captured the hearts of many users. They are a kind of self-evident elegance, interpreting the aesthetic concept of simplicity and uncomplicated.

People prefer these colors, perhaps because they can be cleverly blended with a variety of occasions and styles, like a blank canvas, allowing personality and creativity free to play. White and light colors, but also comes with a kind of purification of the soul, so that people in the busy and noisy find a trace of peace and calm, as if it is the purest language of nature, gently telling the story about the beauty.

01. Material challenges, technical bottlenecks

However,Behind this pure beauty,lies a challenge that garment manufacturers are not aware of. Especially when cotton, linen, or more environmentally friendly special materials are chosen, these materials are favored for their natural, breathable properties, but the cutting process poses a challenge for manufacturers.

Traditional cutting methods are often difficult to manage, especially laser cutting machine, if the technology is not advanced enough, it is easy to produce yellowed edges, black, and even burnt edges of the phenomenon, which not only harms the original aesthetic of the material, but also increases the production costs and time loss, and has become a major bottleneck restricting the quality of enhancement!

02. Comfort is king and experience is paramount

The pursuit of modern consumers for clothing has long gone beyond mere beauty and fashion. In this era of experience and feelings, comfort has become an important yardstick to measure the value of clothing. A piece of clothing, even if the design is novel, if you can’t bring pleasure and relaxation after wearing it, it is difficult to win the favor of consumers.

People are more willing to pay for that comfort from the inside out, because it is an expression of self-care and a direct reflection of the pursuit of quality of life.

03. Technology breaks the mold, innovation leads the way

In the face of such market demands and challenges, an innovative machine called GNM1480T Sliding Table Laser Cutting Machine has been created, which is like a highly skilled craftsman, tailor-made for white and light-colored fabrics. With its unique advantages, this machine has revolutionized the garment manufacturing industry.

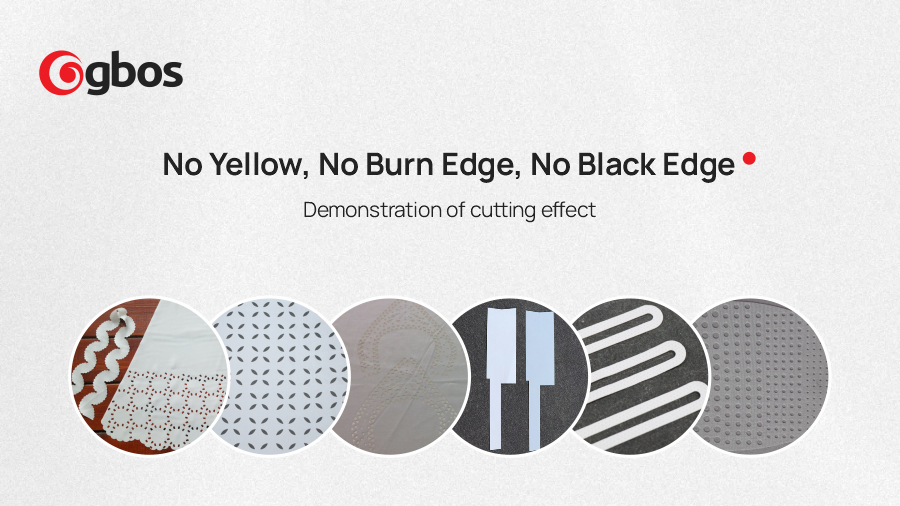

Precise cutting, guarding purity: designed for white and light-colored fabrics, it ensures that the cut pieces are free of yellow edges, scorch marks and black edges, perfectly preserving the original beauty and texture of the material.

Efficient synergy and increased production capacity: Equipped with a dual-head laser cutting system with left and right interactive stencils, this innovative design greatly improves cutting efficiency and shortens the production cycle, so that every piece of fabric can be transformed into a beautiful garment at the fastest speed.

Intelligent control, simplified operation: The introduction of DSP digital control system makes the operation interface simple and clear, greatly reducing the difficulty of personnel training and operation, even novice can quickly get started, reducing human error and improving the overall work efficiency.

Diversified applications, expanding possibilities: In addition to being good at handling white materials, the machine is also capable of cutting seamless materials, with outstanding cutting effect and extremely low probability of bursting glue at the edges after hot pressing, which provides more creative space for apparel designers.

Looking ahead, the apparel industry is waiting for every manufacturer and brand owner to write their own brilliant chapters with more innovative technologies and ideas. In this era of rapid change, the only way to reserve enough strength to meet the challenges of the future and reap a brighter future is to continue to innovate and explore the unknown.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: