Stock Code: 870145

XXP3.1-250N

Reflective Material Laser Cutting Machine

With the unique patented technology of the GBOS LASER, the XXP3.1-250N is superior to similar models in speed and precision.

Marking+ cutting.

Imported metal generator, no sonsumable parts.

User friendly design, inegral forming, Multi dimensional exhausting system.

Unique optical system, leading accuracy, thinner marking line, show perfect details.

Solve the laser processing challenge, no yellow edge, no burn edge and no pecular edge.

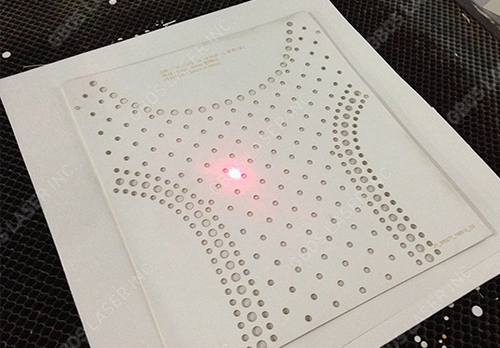

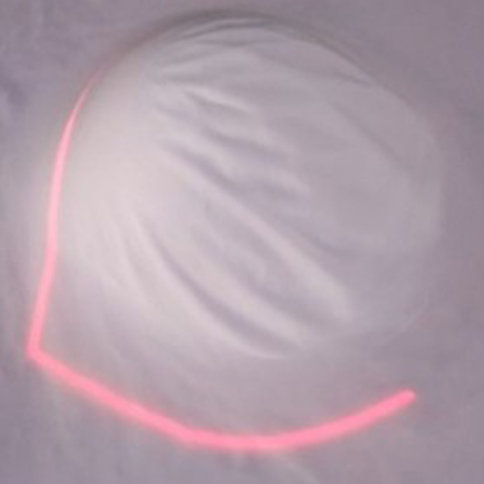

High efficiency perforating, 300 holes per second, 15-20 times than common cutting machines.

| Working area | Gross power | Laser power | Power supply | Dimension | Overall weight | System compatible format |

|---|---|---|---|---|---|---|

| 400*400mm | 5500W | 250W | 220V/32A, 50HZ/60HZ | 1150×1120×1580mm | 280kg | WIN10/11,PLT, DXF,JPG,BMP |

Materials & Samples

- Shoe Accessories

- Leather Goods

- Handbag/Wallet Accessories

- Garment Accessories

- Underwear

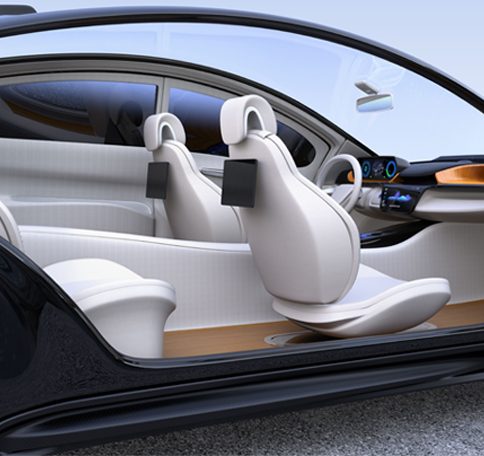

- Automotive Interiors

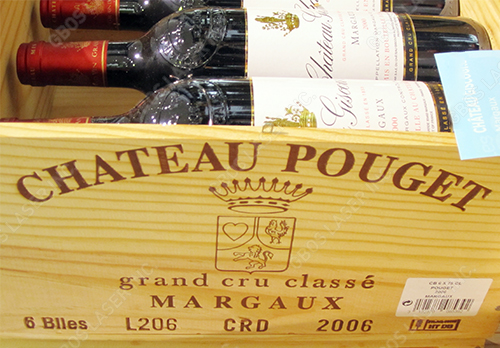

- Craft & Gifts

Expand More +

-

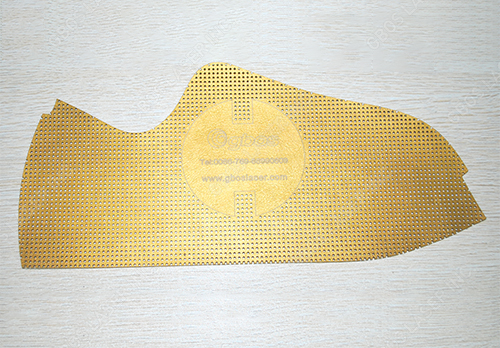

Shoe Accessories Laser Cutting

-

Laser Cutting Marking Shoe Accessories

-

Laser Cutting Sandals Shoe Accessories

-

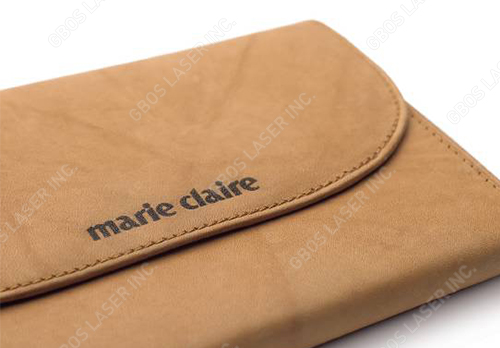

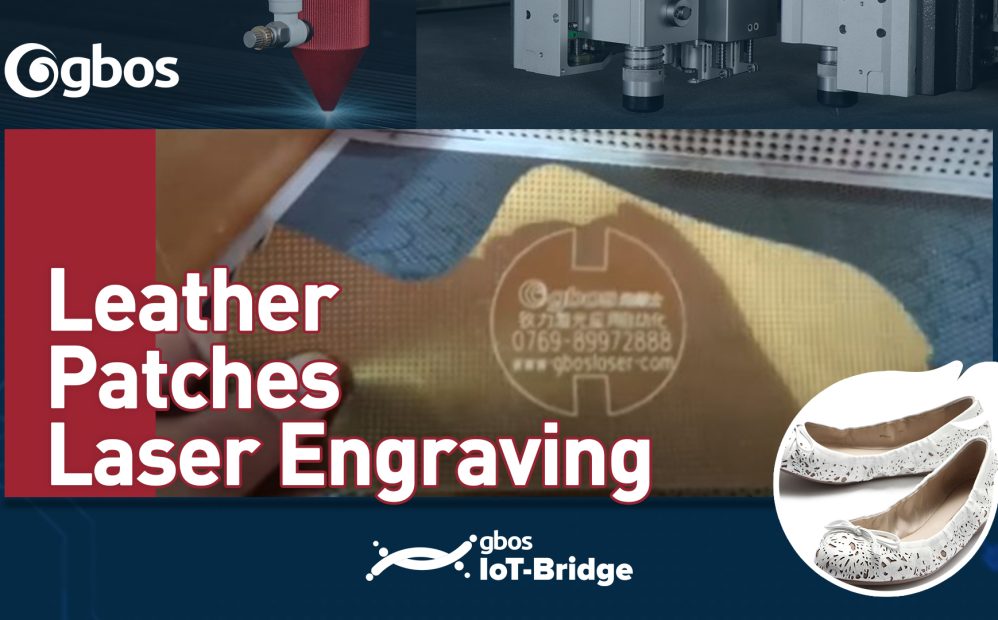

Laser Cutting Engraving Leather

-

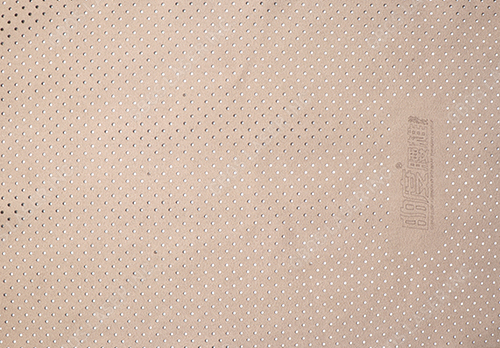

Car Seat Leather Laser Engraving

-

Laser Perfoarting Leather Holes

-

Leather Headrest Laser Engraving

-

Leather Wallet Laser Engraving

-

Laser Engraving Leather Wallet

-

Leather Bags Accessories Laser Cutting

Expand More +

Expand More +

Expand More +

Expand More +

Functions & Modules

-

Purify and treat the smoke and waste gas generated during the cutting processMore Details

-

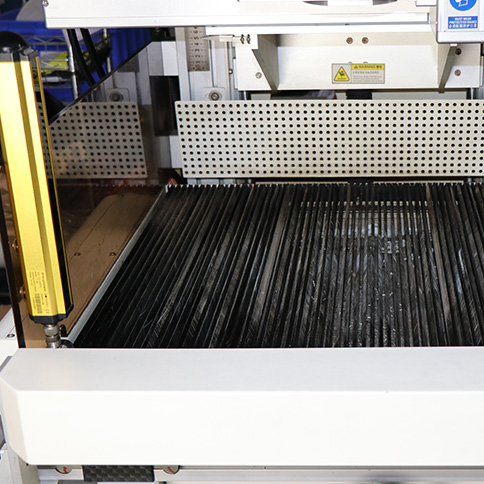

The advantages of using a blade mesh panel as the cutting table for CO2 laser marking machine are as follow:More Details

Expand More +

Industry Solutions

-

Leather Goods

-

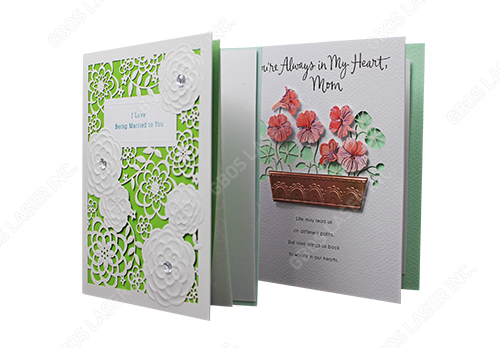

Greeting Card Industry

-

Garment Industry

-

Automotive Interior Industry

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: