-

Industry Trends/Customer Challenges

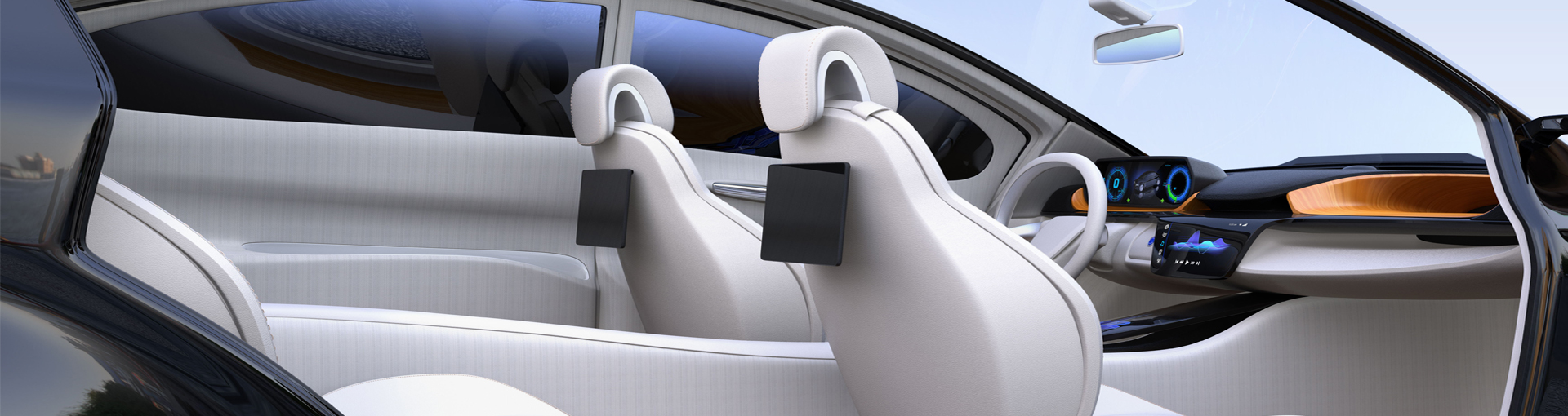

Industry Trends/Customer ChallengesThe automotive interior industry involves a wide variety and large quantity of materials. From cutting large-format materials like seats and floor mats to precision processes such as marking function buttons and engraving interior patterns, manufacturers face tough challenges, including high labor costs, low precision, poor quality, and low production efficiency.

The rapid rise of new energy vehicles has dramatically increased the demand for high-quality, aesthetically pleasing automotive interiors. Comfortable interiors are now an essential factor in consumers' vehicle choices.

In response to these market changes, automotive interior manufacturers and brands urgently need to overcome inefficient production practices. They seek multifunctional, all-material, high-precision, and labor-saving digital machinery to meet the new personalized consumer demands.

-

Advantages of GBOS Solutions

Customized Solutions: Tailored cutting solutions for various flexible automotive interior materials like leather, foam, and composite materials, covering multiple processes such as cutting, marking, engraving, and punching to achieve optimal production outcomes.

Fully Automated Process: Highly automated procedures integrated with a self-developed software system reduce labor costs while enabling quick order response, meeting the needs of personalized and customized production.

Digitalized Production: An IoT system with data visualization enables real-time monitoring of production data and equipment status, maximizing efficiency for digital production management and control.

- Automotive Interior (Flexible Material) Cutting Solutions

- Automotive Exterior Materials Laser Cutting Solutions

- Shaped Materials Laser Cutting & Trimming Solution

- Automotive Interior Laser Marking Solutions

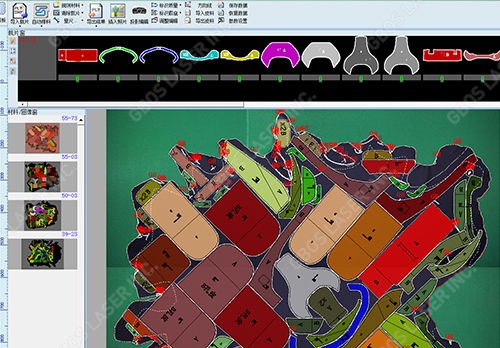

- Automotive Interior Leather Nesting Sys

-

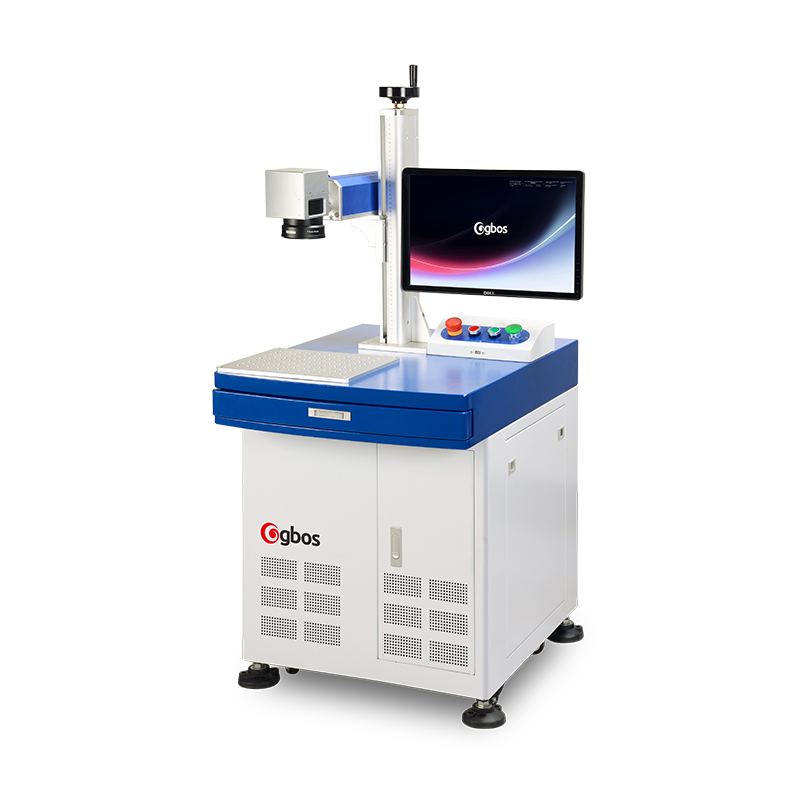

XXP3-250High Speed Galvo Birthday Greeting Card Wedding card Laser Engraving Cutting Marking MachineMore Details

-

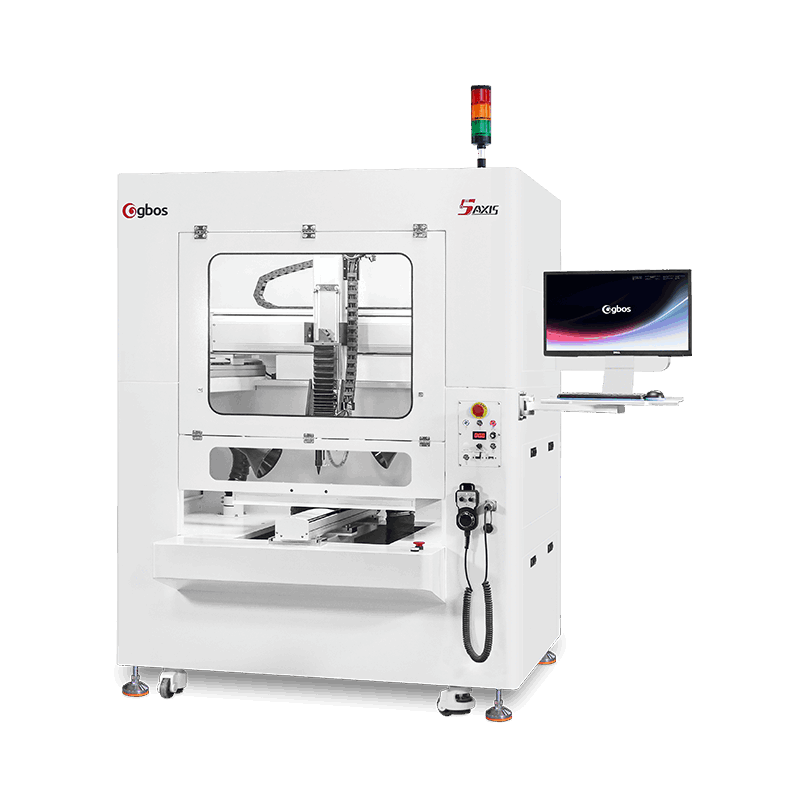

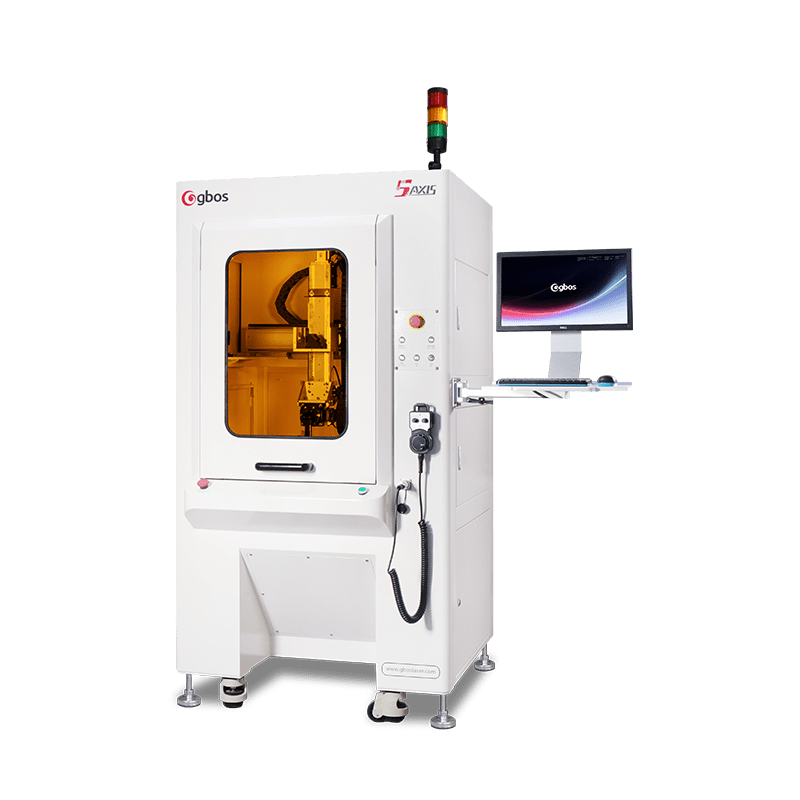

GN502-3D-EPGN502-3D-EP Five-axis Intelligent CO2 Laser Cutting Machine With Dual Working Tables.More Details

-

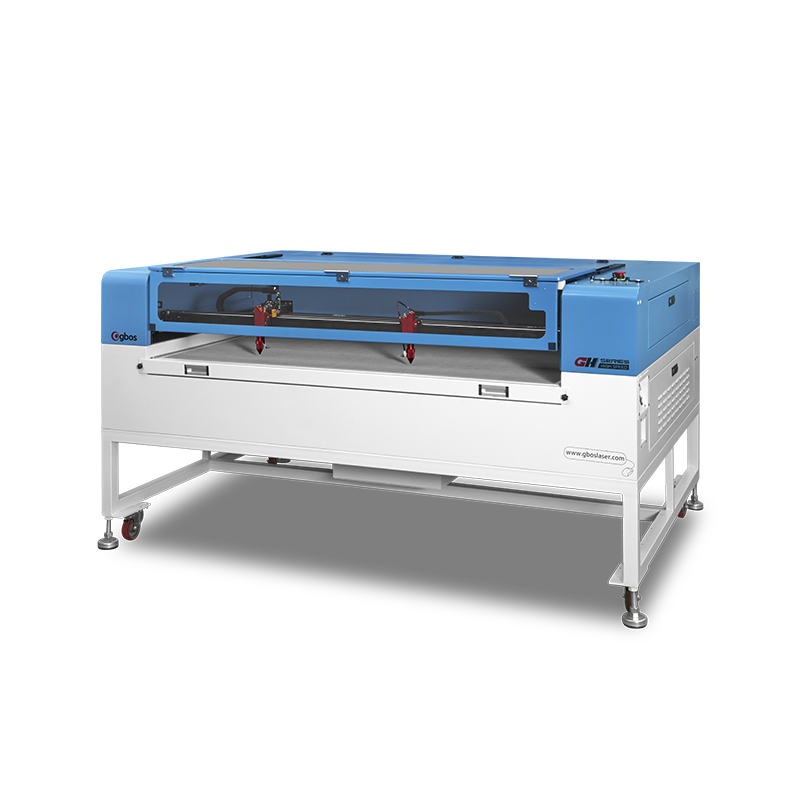

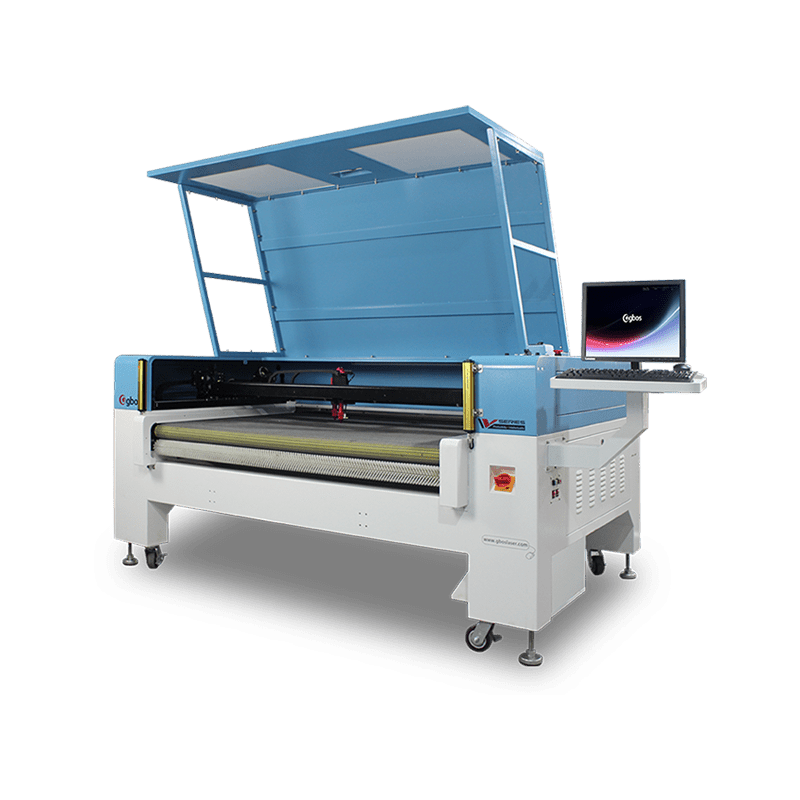

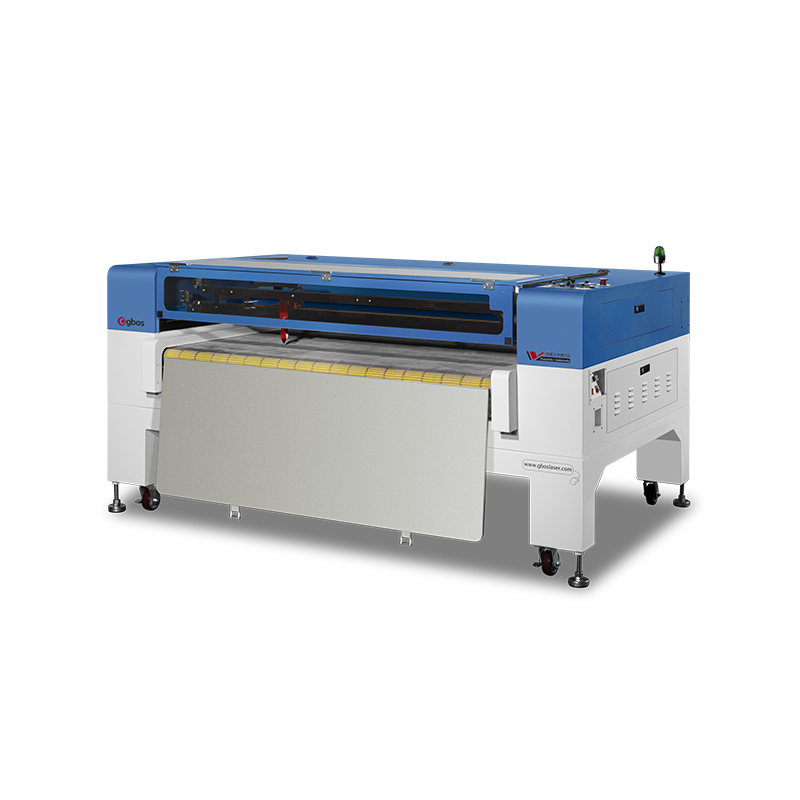

GH1812T-AT-SCCDTwo heads Intelligent Auto Feeding Laser Cutting Machine with Supper CameraMore Details

-

Jan 17,2026The true refinement of automotive interiors is often hidden in the details you don’t immediately see. From a single piece of plastic raw material to a contoured trim part that fits seamlessly into the cabin, the precision and efficiency of the cutting process directly define the upper limit of product quality—and ultimately shape a manufacturer’s core competitiveness. 01 The Dual Challenge of Cutting Complex Automotive Interior Components As you sit inside a vehicle and run your fingers along the smooth curves of the center console or the precisely cut openings on the door panels, you probably don’t stop to think about how these complex, contoured parts are produced with such consistency. For automotive component manufacturers, however, achieving this level of precision has long been a hidden pain point in production. Traditional stamping dies are bulky and costly to change over, making them ill-suited for customized or irregularly shaped interior parts. Manual trimming, on the other hand, relies heavily on operator experience, often resulting in inconsistent accuracy, excessive burrs, and additional finishing processes that consume time, labor, and may even compromise part precision. As a result, the machining of complex interior parts is often trapped in a dilemma between low efficiency...

-

Aug 01,2025As the automotive industry experiences slower growth, cost reduction and efficiency improvement have become critical for suppliers to remain competitive. In this new normal, companies must restructure their strategies and operational models to overcome production challenges while seizing emerging opportunities. The acceleration of electrification and the upgrade of automotive interiors are driving a major industry transformation. Autonomous driving, new energy, and connected technologies are continuously reshaping the supply chain landscape. Leading companies are boosting factory efficiency through technological innovation—strategic upgrades of manufacturing bases are becoming essential to stay competitive in the digital era. Smart Nesting Unlocks New Levels of Leather Utilization In the fast-evolving automotive market, premium car seats start with precision leather cutting. Traditional manual nesting relies heavily on experience and often results in low material utilization. The GBOS ITS5-3012 Intelligent Leather Nesting System is transforming this process, bringing automation and efficiency to the forefront. Backed by GBOS’s deep expertise in automotive interior and exterior manufacturing, the Intelligent Leather Nesting System leverages years of algorithm optimization to deliver highly efficient nesting, significantly reducing leather waste compared to manual operations. Equipped with a 40MP industrial camera, it accurately captures leather contours and automatically stitches multiple images, enabling continuous multi-piece nesting....

-

Jun 20,2025Amid the wave of consumption upgrading, leather has become a favorite in sectors such as automotive interiors and fashion accessories, thanks to its unique texture and durability. Booming Leather Applications and Evolving Market Needs In the automotive industry, premium leather seats and interior panels convey a strong sense of luxury and comfort. Meanwhile, in the bags and handbags market, leather products—with their wide variety of styles and personalized designs—cater to consumers’ growing pursuit of quality and fashion. Consumers are no longer satisfied with basic functionality; instead, they increasingly seek products with unique, customized designs. This shift is driving the leather industry to continuously explore the boundaries of innovation. Challenges and Dilemmas Facing Leather Manufacturers Behind the market opportunities, leather manufacturers face numerous challenges. On the supply side, high-quality leather resources are scarce and subject to significant price fluctuations, making cost control increasingly difficult. In terms of market competition, brands are engaged in intense rivalry, while consumers are placing higher demands on product quality, design, and brand identity. To stay competitive, companies must strike a balance between improving production efficiency, enhancing product quality, and building a strong brand image. Reforming and Reshaping the Leather Industry Landscape 1.Leather Cutting Solutions: Precision and...

-

Oct 23,2024The development of China’s automotive industry has transformed from weak beginnings to remarkable prosperity, marking a significant historical chapter. As the market shifts from rapid expansion to stable competition, the automotive sector stands at a new historical juncture, facing fresh opportunities for globalization. This is not just a challenge but a golden period for Chinese automotive brands to showcase their strength on the global stage and strategize anew. 01 Innovative Manufacturing in Automotive Interiors: Key to Enhancing Market Competitiveness Among various manufacturing stages, the design and production of automotive interiors are crucial. They impact vehicle aesthetics, functionality, consumer experience, and market competitiveness. With increasing demands for intelligent, high-quality, and timely delivery from brands and manufacturers, interior manufacturers must adopt effective strategies, innovating and optimizing processes to meet these high standards. 02 Growth Strategies for Interior Manufacturers To maintain a competitive edge, interior manufacturers should implement strategies such as increasing R&D investment, promoting technological innovation, enhancing manufacturing processes, ensuring product quality and consistency, and utilizing advanced digital production management systems to improve decision-making and responsiveness to market changes. GBOS excels in implementing these strategies, offering one-stop smart cutting and innovative process solutions for automotive interiors. This includes: Leather Layout and Cutting...

-

Feb 08,2023Comfortable, Luxurious Car Seats are the Preferred Choice. Consumers are no longer limited to the aesthetics of their cars, but are paying more and more attention to the aesthetics, comfort and personalisation of the interior when purchasing. As an important part of the car’s interior, consumers are particularly demanding about car seats. For example, some of the existing ventilated seats are not well ventilated due to irregular breathable holes, so car owners will choose a more breathable car seat to replace the original seat to maintain a comfortable and breathable feeling; or replace it with a set of tailor-made seats, which can not only enhance the car’s class, highlight the unique personality, but also add a sense of comfort. As a result, the comfort of car seats and innovative manufacturing processes have become a key concern for many manufacturers of automotive interiors. If punching is continuously performed with automated machines, when different hole diameters are required, customized punching needles need to be replaced and the process is unique and only applicable to the punching process. GBOS, as a service provider offering innovative process solution, has developed the XXP3-180 intelligent high-speed laser...

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: