-

Garment Industry

-

Lingerie Industry

-

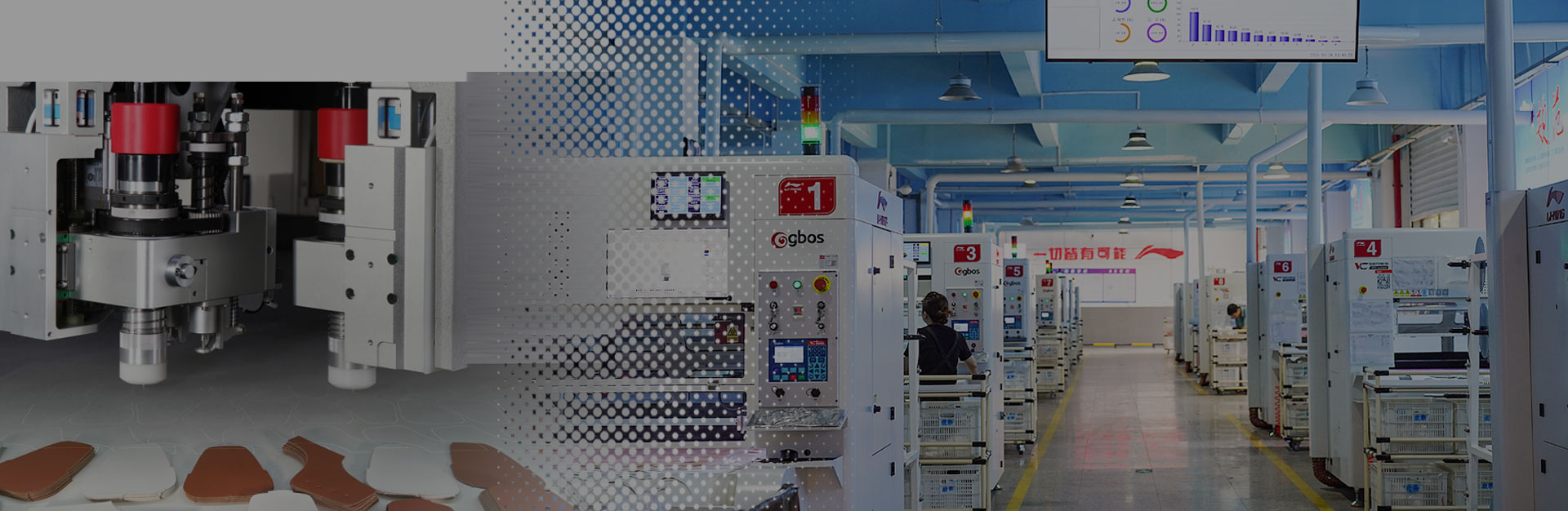

Footwear Industry

-

Smart Wearable Industry

-

Garment Accessories Industry

Products Center

-

Trending

Trending -

CO2 Laser

CO2 Laser

cutting machine -

Laser Marking Machine

Laser Marking Machine -

Laser Denim

Laser Denim

Finishing System -

Other Automation

Other Automation -

Digital Knife

Digital Knife

Cutting Systems -

Discover More+

-

X LABEL 180Digital Laser Die CutterMore Details

Boosts productivity by 10X.

VisionScan: Precise cutting for any soft, non-metallic label.

Efficient feeding, edge cutting, serrated cuts, hollowing, and engraving.

Comprehensive label laser solutions: cutting, carving, marking, and more.

-

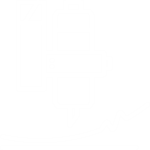

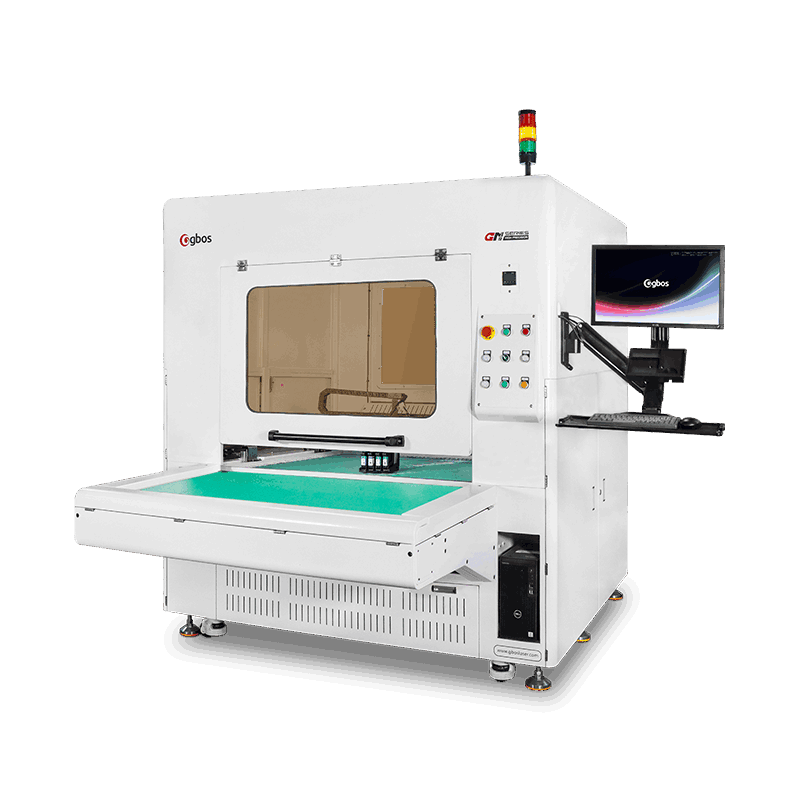

GNM1280T-30ASLIDING TABLE LASER CUTTING MACHINEMore Details

High speed and stability

No burned edge and no yellow or black edge

Interactive dual-head, more waste-saving

for odd numbers of patterns(optional)

-

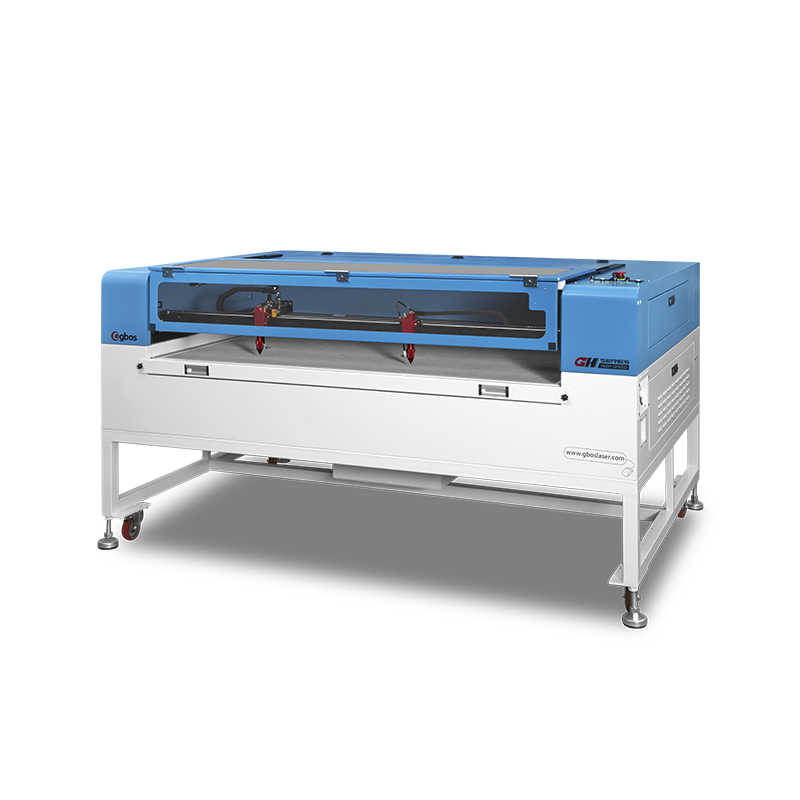

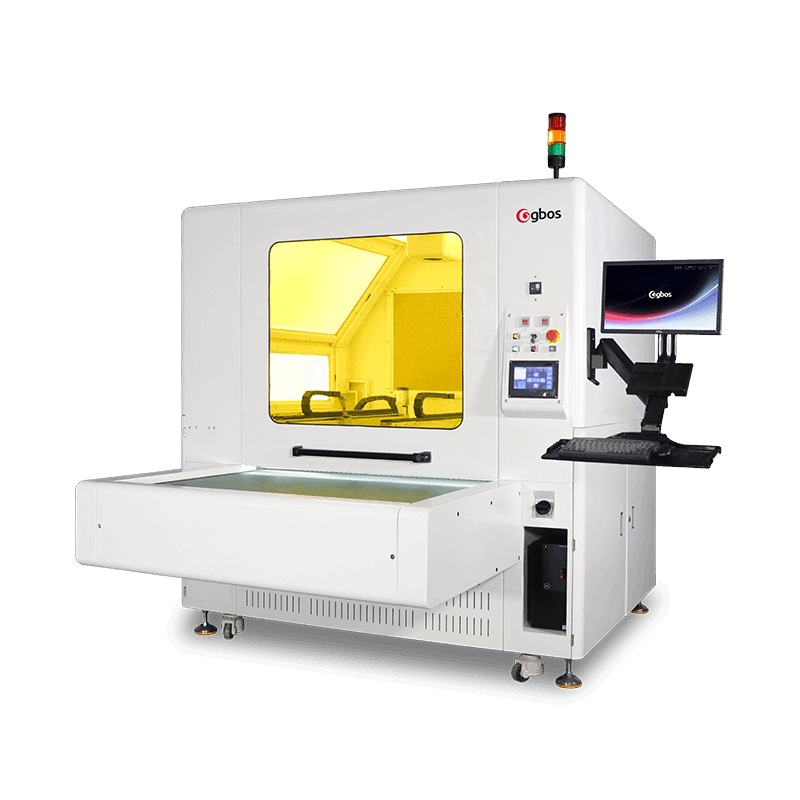

GH1610(TT)-AT-SCCDCO2 Laser Cutting Machine for Sublimation Digital Printing FabricMore Details

Smart zoom

Border cutting

No yellow, burnt edge

Super camera positioning

Automatic extraction of contour

Automatic locking of knitted fabrics

-

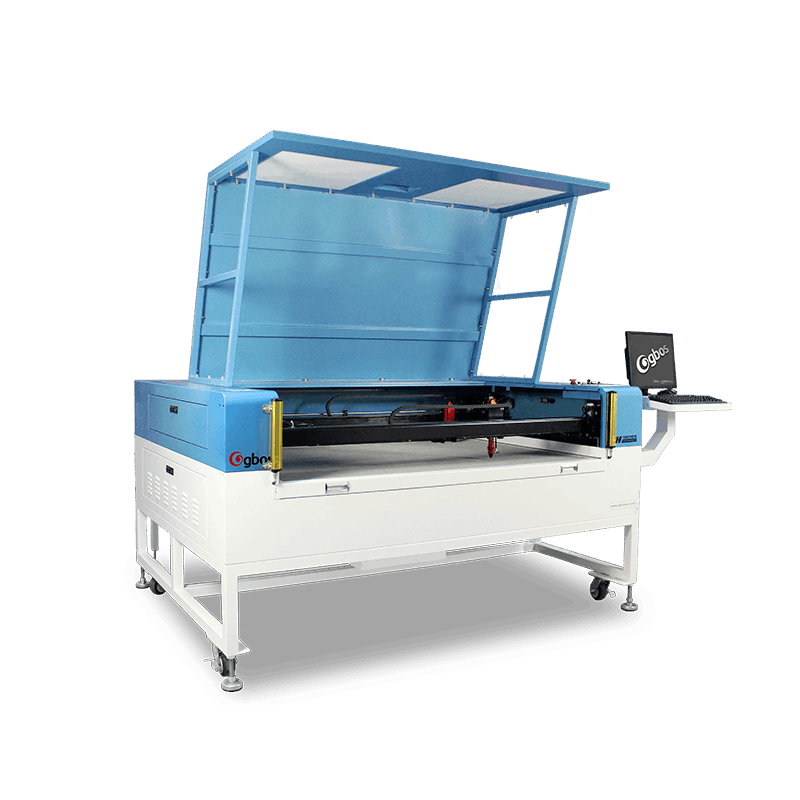

GHMulti-Function CO2 Laser CutterMore Details

Variety of sizes to meet your needs.

18-year classic model, enduring quality.

Modular design for flexible feature configurations.

Options of single/dual/quad laser heads.

Fast and precise, fully compatible with IoT Bridge.

-

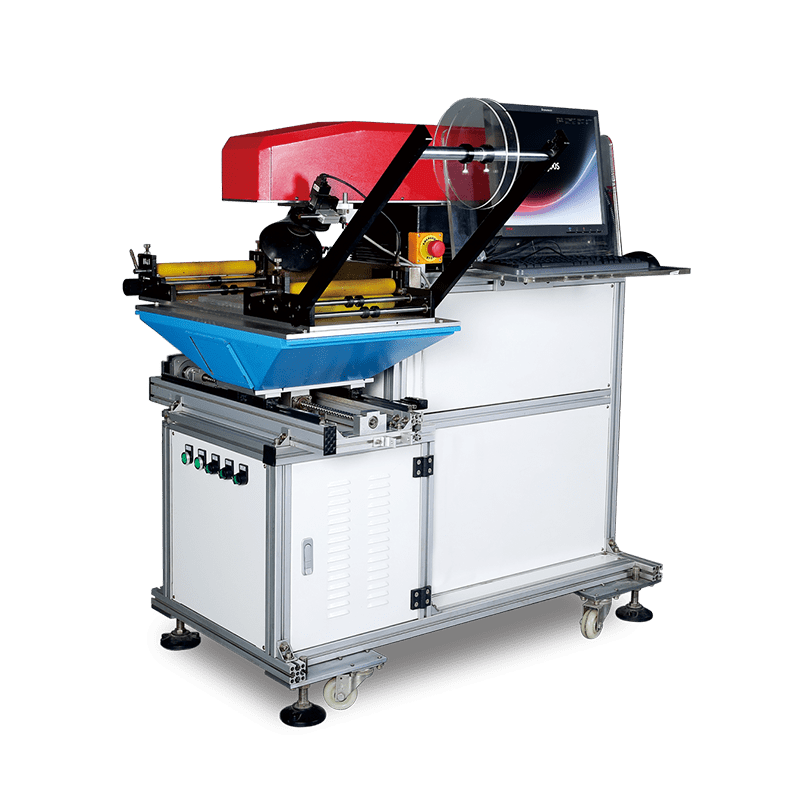

XXP3S-180XXP3S-180 Automatic Feeding Laser Marking MachineMore Details

Especially suitable for rolling materials.

More than 10 times that of ordinary auto feeding cutting machine.

The world's only one automatic feeding marking system customized for rolling materials.

PUV and other materials need batched perforation,engraving, and marking applications.

Compared with the common marking machine,the efficiency increases more than 3 times.

-

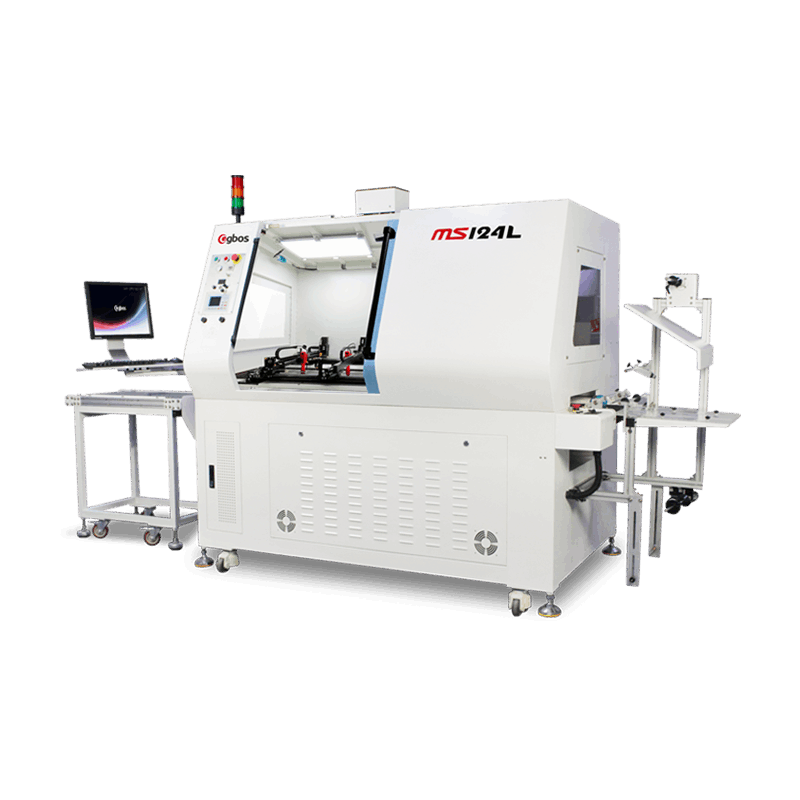

XXP3-180-CCD3D Dynamic Camera Positioning Laser Marking SystemMore Details

Imported metal generator, no sonsumable parts.

Laser marking, engarving, marking, perforating all in one.

User friendly design, inegral forming, multi dimensional exhausting system.

Unique optical system, leading accuracy, thinner marking line, show perfect details.

Solve the laser processing challenge, no yellow edge, no burn edge and no pecular edge.

High efficiency perforating, 300 holes per second, 15-20 times than common cutting machines.

-

XXP5-600-AWLaser S-Denim 6.0 Dry Process SolutionsMore Details

S-Denim 6.0 technology: Process 6.0; Technology 6.0; Ecology 6.0; Pay respect to traditional craftsmanship with digital technology.

Large-scale production of garment and trousers.

S-HDR technology.

Multi-functional high-end personality customization.

Digitization processes, a homage to traditional craftsmanship.

Three-axis laser scanning system and with CO2 RF metal tube.

Four sliding table further improve the efficiency, the 'cloud' shares ideas, and the S-HDR technology is more realistic, three-dimensional, and delicate.

-

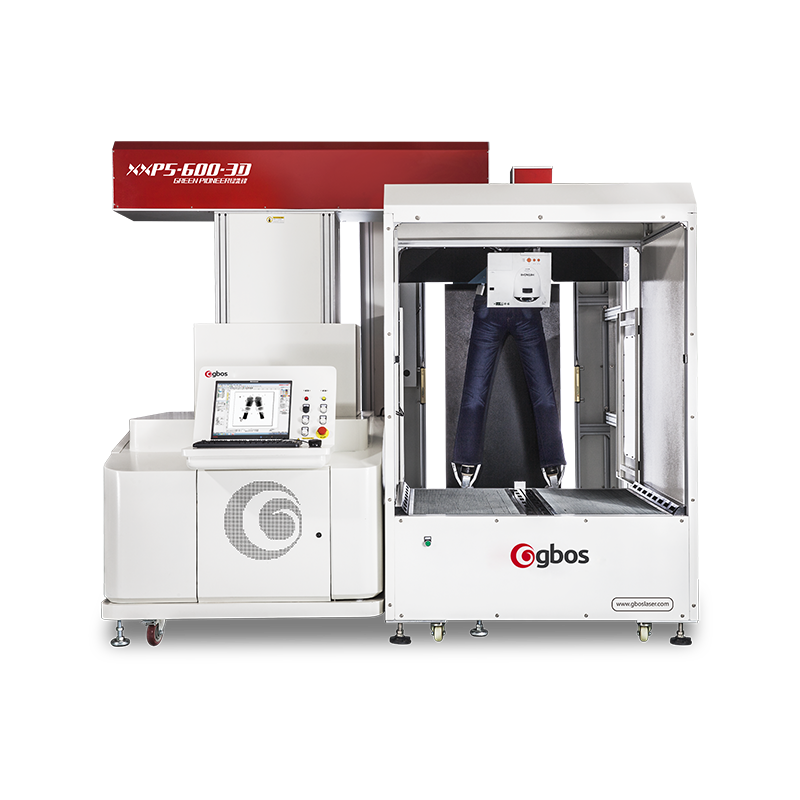

XXP5-600-3D3D Laser Washing System for Denim JeansMore Details

Digital control,double working area including mannequin ro ensure the high efficiency and laser engraving effect.

-

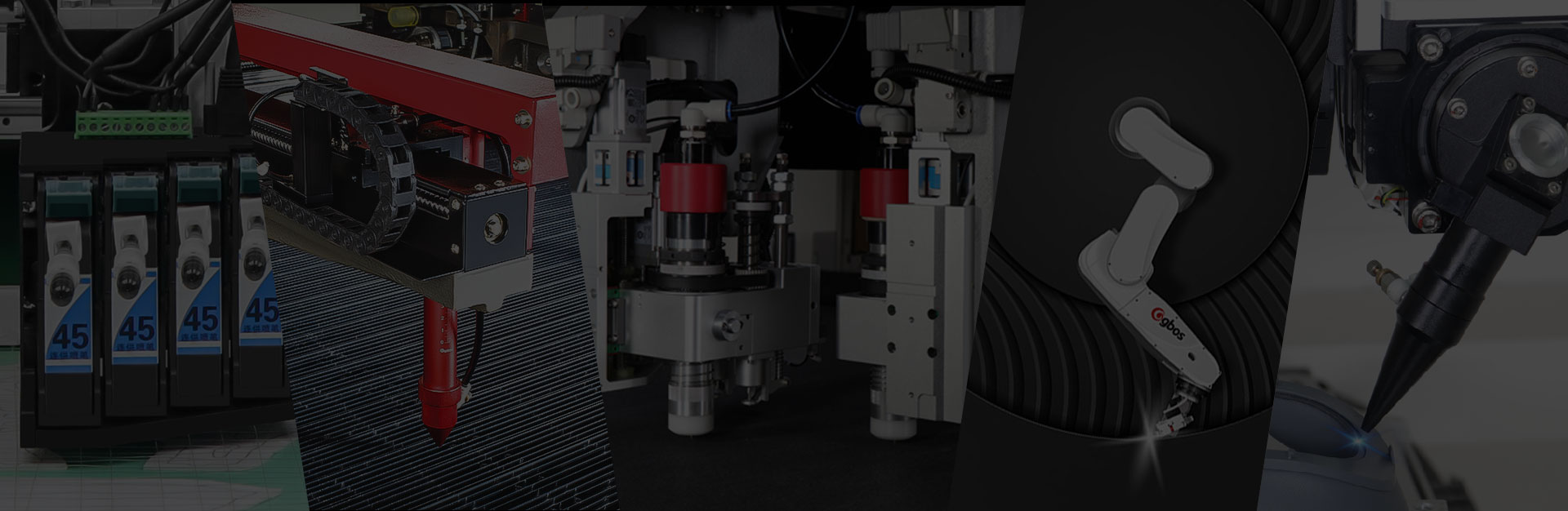

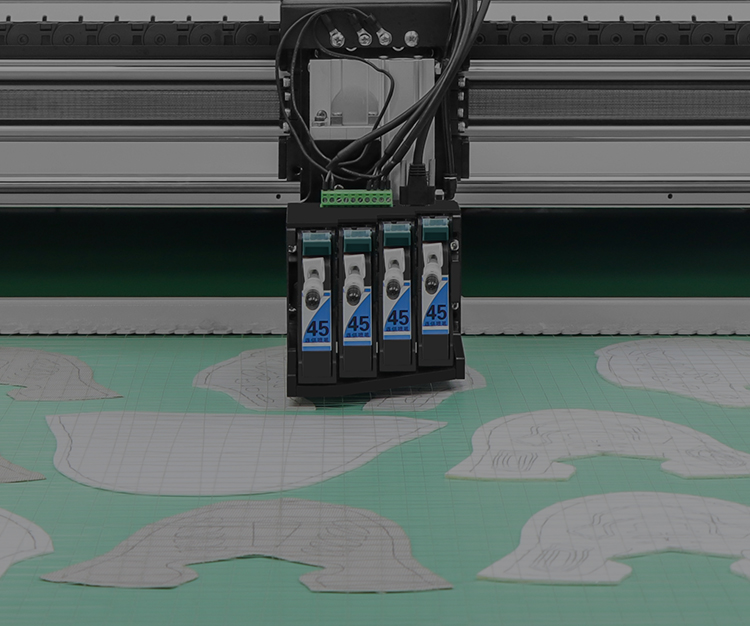

SP-GH1280-AT-SCCDCartridge Type Line Printing Machine with AI SCCD VisionScan SystemMore Details

Replace traditional silk screen printing line machine.

More than 6 times faster and efficiency than traditional machine.

Isolation of feeding, processing and receiving area is realized by conveyor belt.

With AI VisionScan system, achieve: any shape positioning without manual alignment required, arbitrary placement of materials…

-

LA-GN1280TT-AT-SCCDAI SCCD Double Head Async 5G Smart Auto Inkjet Marking ShoeMore Details

IoT system.

Auto drying system.

Press materials system.

Automatic feeding system.

AI VisionScan identity system.

Applicable to a variety of inks.

-

Oscillating Knife Digital Cutter for Flexible MaterialsSuitable large-format materialsMore Details

Digital cutter with double-head asynchronous linear guide, rack and pinion drive. And also for punching four different size holes at the same time.

About GBOS

Discover our Latest News

- Exhibition & Events

- Industry News

- News

![Small Batch& Customized–Leather Sofa [One-stop] Intelligent Nesting + Cutting Small Batch& Customized–Leather Sofa [One-stop] Intelligent Nesting + Cutting](https://www.gboslaser.com/wp-content/uploads/2024/03/2024031611520755fd2.jpg)

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: