As one of the world’s largest and most professional shoe machinery exhibitions, the Guangdong International Intelligent Shoe Machinery & Equipment Exhibition brings together global giants of the footwear industry, cutting-edge innovative concepts, and technological achievements.

From May 28th to 30th, GBOS debuted its brand-new machine models and intelligent solutions at this technological extravaganza, capturing extensive attention and injecting upgrading momentum into the intelligent manufacturing sector of the footwear industry.

Orders Poured In as Technical Strength Won Warm Praise

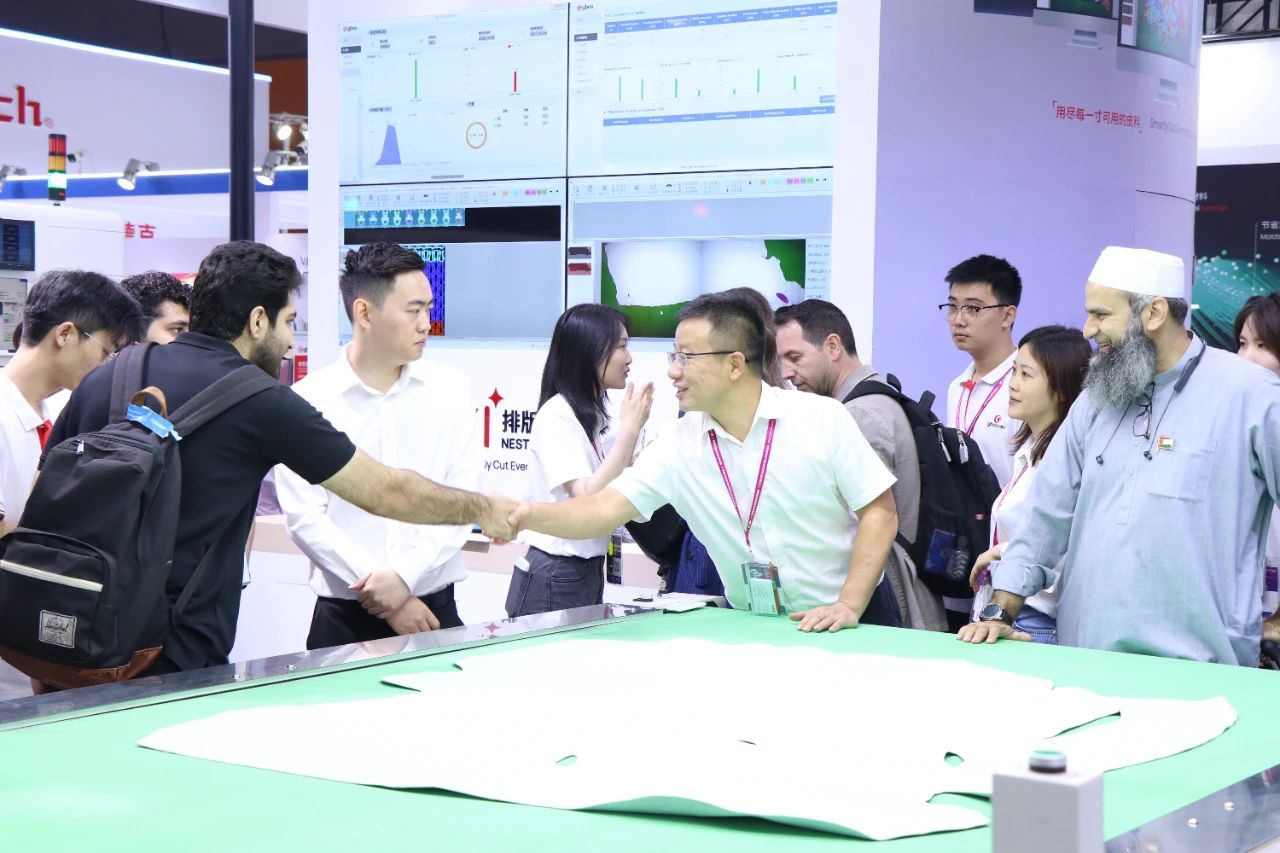

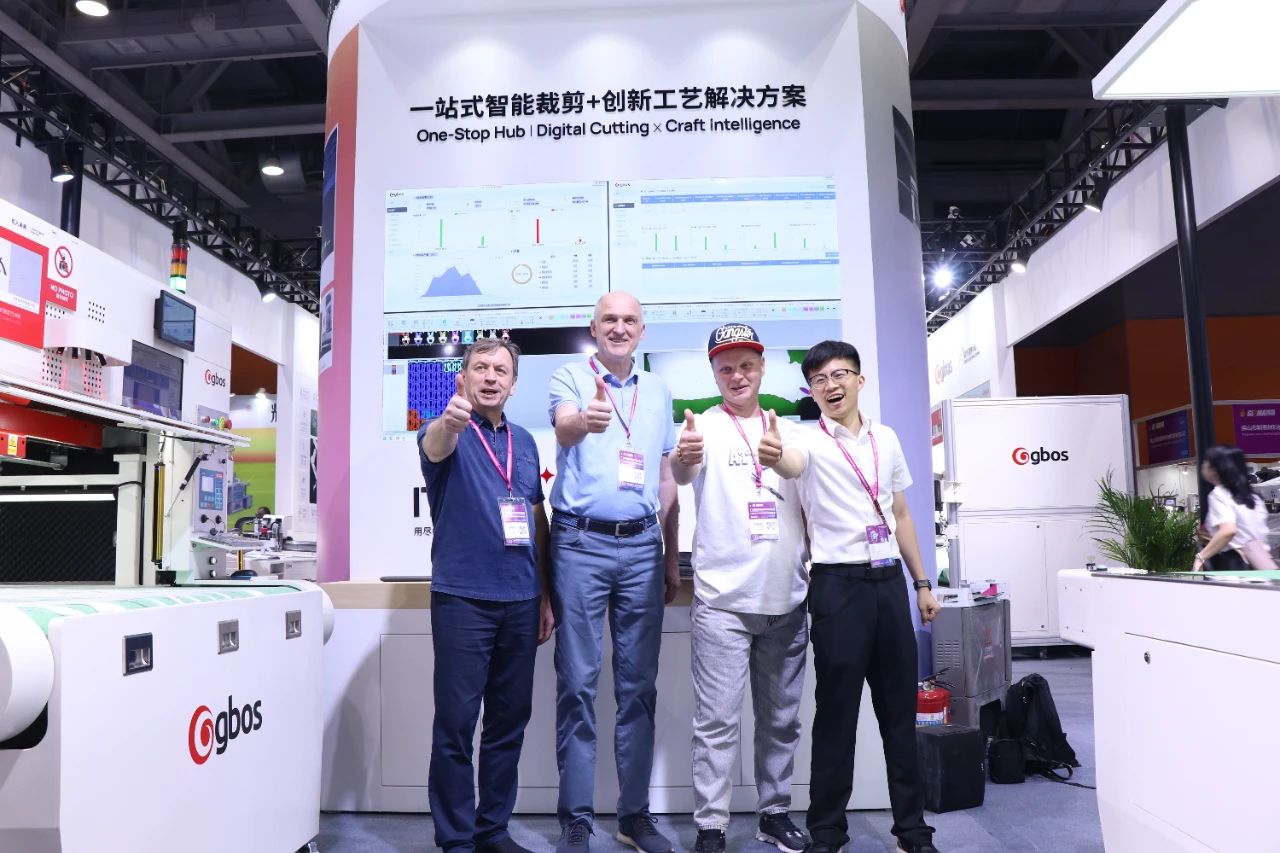

During the exhibition, the GBOS booth was bustling with activity, attracting numerous industry professionals from both home and abroad to stop by, visit, and inquire.

Supply chain teamsfrom various leading brands and Southeast Asian purchasers stopped by, and many enterprises reached cooperation intentions on the spot. Its technical strength and product competitiveness have been highly recognized by the market.

Ingenuity Pours into Exquisite Works, Subverting Traditional Craftsmanship

At the new product launch conference, Mr. Liu Wen, CEO of GBOS, unveiled the highly anticipated leather intelligent cutting assembly line KC1625TT-RT-2P-ITS3-SP.

This equipment integrates leather nesting, coding, and cutting, completely breaking through the bottleneck of traditional manual operations, and bringing a brand-new production model and efficient solutions to footwear enterprises.

- Efficient Operation and Precise Control: While significantly improving operational efficiency, it ensures high-precision and consistency in material cutting, making it suitable for mass production. It avoids defective products caused by secondary alignment cutting, thus reducing leather costs and labor costs.

- Cost Reduction and Automation Advantages: Reduces reliance on skilled labor, cuts leather costs through intelligent nesting, and achieves full automation of production processes with the optional genuine leather automatic double-feeding system.

Technical Highlights:

ITS3 Leather Nesting System

Dual-head Asynchronous Cutting System & Waste Suction

Cartridge-type Inkjet Coding Device

Laying Out the Smart Manufacturing Path, Empowering the Future with Technology

In today’s footwear industry, the wave of intelligentization is sweeping through at an unprecedented pace, bringing brand-new transformations and development opportunities to the traditional industry.

GBOS drives the footwear industry’s transformation towards automation and digitization with innovative equipment and intelligent solutions, continuously empowering the upgrading of smart manufacturing in the shoe industry and leading new directions for industry technological development.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: