Comfortable, Luxurious Car Seats are the Preferred Choice.

Consumers are no longer limited to the aesthetics of their cars, but are paying more and more attention to the aesthetics, comfort and personalisation of the interior when purchasing. As an important part of the car’s interior, consumers are particularly demanding about car seats.

For example, some of the existing ventilated seats are not well ventilated due to irregular breathable holes, so car owners will choose a more breathable car seat to replace the original seat to maintain a comfortable and breathable feeling; or replace it with a set of tailor-made seats, which can not only enhance the car’s class, highlight the unique personality, but also add a sense of comfort.

As a result, the comfort of car seats and innovative manufacturing processes have become a key concern for many manufacturers of automotive interiors. If punching is continuously performed with automated machines, when different hole diameters are required, customized punching needles need to be replaced and the process is unique and only applicable to the punching process.

GBOS, as a service provider offering innovative process solution, has developed the XXP3-180 intelligent high-speed laser marking machine as an innovative process applied to the connection of comfort and visual interface in automotive interiors, which can complete various punched pattern designs without a mould, change the drawing file with a single click, effectively save the cost of opening a mould and complete personalised processes such as laser perforating, punching, marking and engraving at one time.

The company’s products are designed to carry more innovative applications to meet consumer demand for sensory and sensory comfort, and to satisfy OEM audits of craft products.

The best technology, innovative concept.

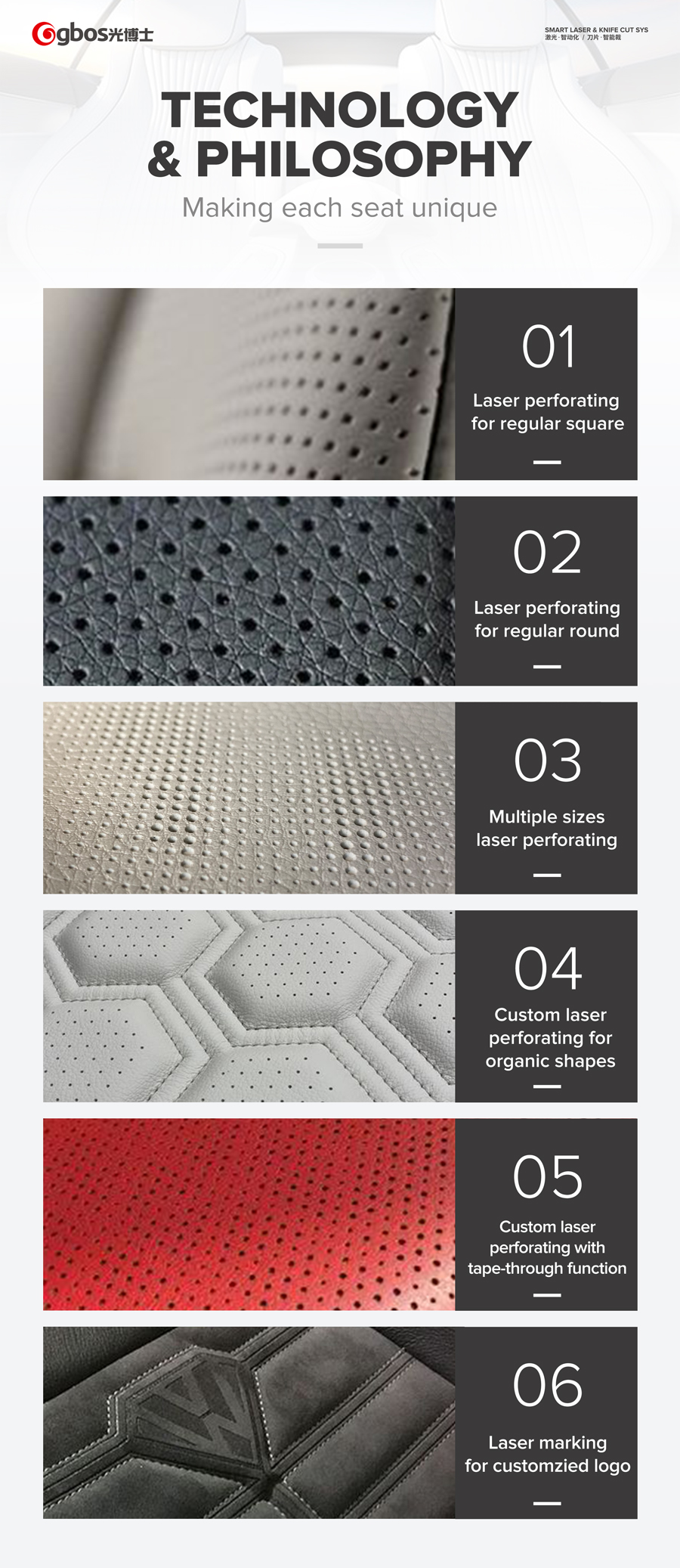

Choose to use the laser perforation process to create round, diamond, square or irregular holes in the leather seats of your car, using the laser marking and engraving process to create fine lines, and complex personalised floral effects to create layers on the leather surface.

The different shapes, patterns and novel arrangements add a sense of luxury to the interior, maintain a wealth of detailing and keep the process innovative.

Laser technology, pioneering a new style of car seat.

Contact for more now!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: