Over the past decade, major e-commerce shopping festivals like “618” and “Double 11” (Singles’ Day) have evolved from marketing promotions into nationwide consumer celebrations. Fueled by advances in internet technology and shifting consumer habits, these events now see a dramatic surge in online sales every year, with e-commerce platforms consistently reporting record-breaking transaction volumes during each festival.

E-Commerce Booms Drive Explosive Market Demand

According to relevant data, each major shopping festival sees exponential growth in the sales of apparel, footwear, and leather goods. As consumer expectations continue to evolve, there is a rising demand for personalized and diverse products. Trendy designs and high-quality craftsmanship have become top choices in shoppers’ carts.

The explosive market demand brings mixed feelings for manufacturers. On one hand, they’re thrilled by the surge in orders; on the other, they’re challenged by the pressure to fulfill those large volumes within tight deadlines.

Production Bottlenecks Exposed: Traditional Manufacturing Struggles to Keep Up

Faced with the explosive surge of orders during e-commerce shopping festivals, the shortcomings of traditional production models become increasingly evident. In particular, material cutting—a critical step in the manufacturing process—suffers from low efficiency and poor precision when done using conventional methods. These limitations make it difficult to meet the demands of large-scale production. Additionally, high labor costs and extended production cycles further hinder the ability to deliver on time.

Even with extended work hours and overtime shifts, many manufacturers still struggle to deliver orders on time. This not only affects brand reputation but also risks losing future business opportunities. Breaking through production bottlenecks has become an urgent challenge for manufacturers seeking to stay competitive in today’s fast-paced market.

Flagship Digital Blade Cutting Machine: Redefining the Standard for Production Efficiency

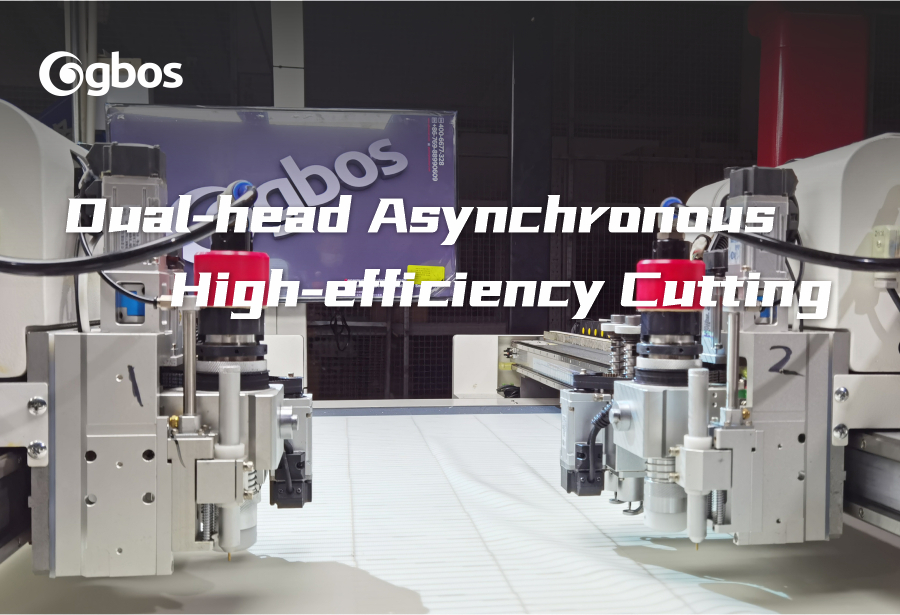

The all-in-one precision cutting solution — VC9-1616TT — is designed to help manufacturers break through production bottlenecks. Engineered with powerful capabilities, this flagship machine excels at multi-layer cutting of a wide range of auxiliary and standard materials, significantly expanding production versatility and efficiency.

In terms of cutting efficiency, the VC9-1616TT features a dual-head asynchronous cutting system that breaks the speed limitations of traditional single-head machines.

The two cutting heads work efficiently in tandem, significantly enhancing cutting speed and accelerating the production pace. This allows manufacturers to complete large volumes of cutting tasks within a short timeframe.

In terms of production process optimization, the multi-layer automatic clamping and feeding system enables full automation. With minimal manual intervention, it precisely controls the feeding process to ensure smooth and flat material delivery, achieving dual optimization of production efficiency and processing accuracy.

The projection preview positioning system makes operation more intuitive and convenient. Operators can instantly preview layout arrangements, plan cutting strategies in advance, optimize every step of the production process, reduce errors, and enhance overall efficiency.

Additionally, the machine body is crafted using an integrated casting process, ensuring durability and resistance to deformation under heavy workloads. This significantly extends the machine’s lifespan and helps manufacturers save on replacement costs.

With its outstanding performance and innovative design, the VC9-1616TT has become a powerful ally for manufacturers facing the pressure of e-commerce shopping festival orders. It helps businesses boost their market competitiveness and stand out in a fiercely competitive landscape.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: