-

Industry Trends/Customer Challenges

Industry Trends/Customer ChallengesFor sports underwear, more and more unlimited size lingerie demands excellence line orders (small volume orders), how to reponse quickly?

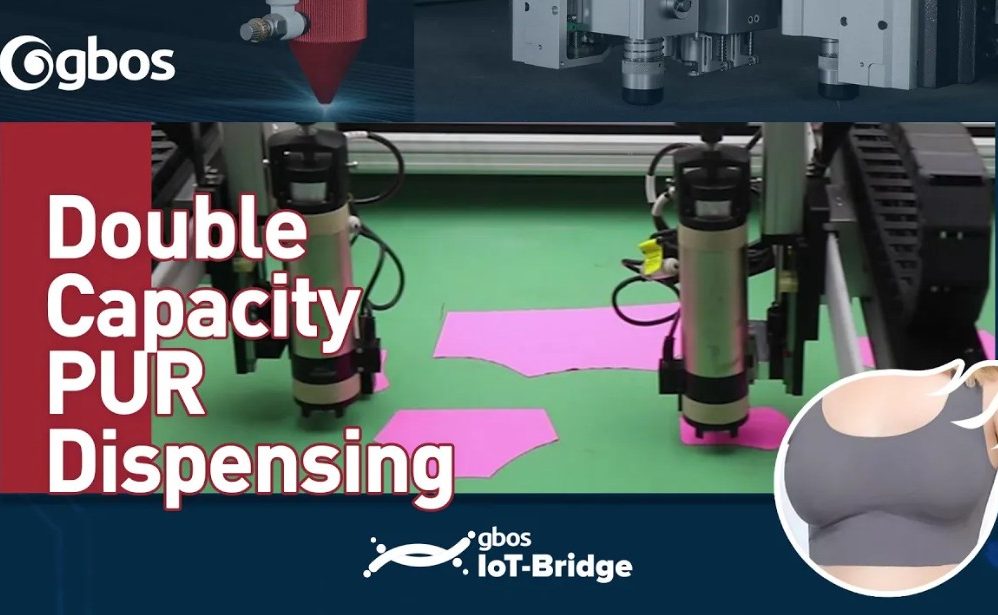

Sewfree® underwear had become the new trends in these years.

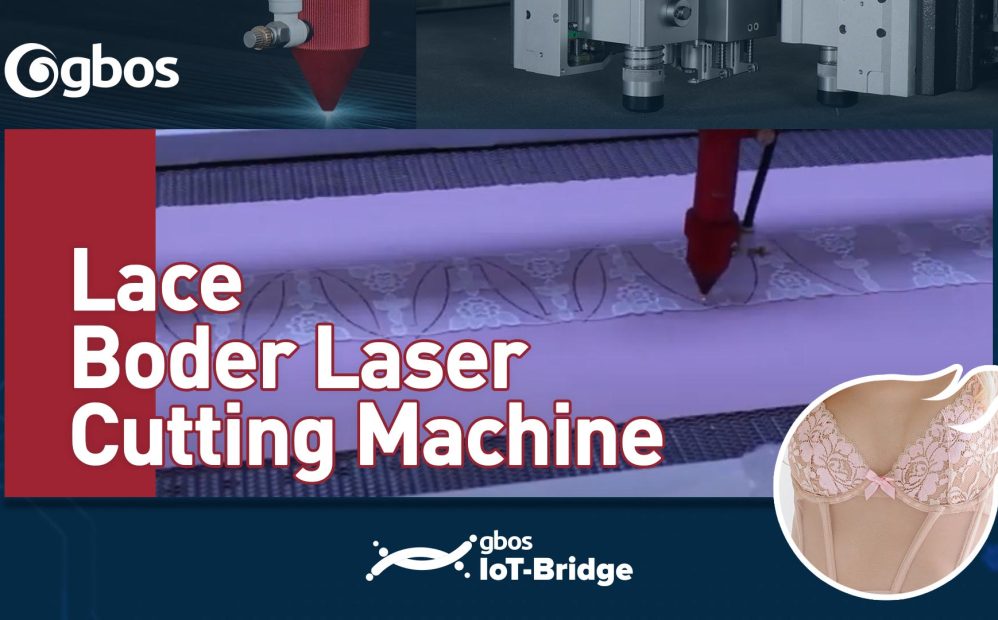

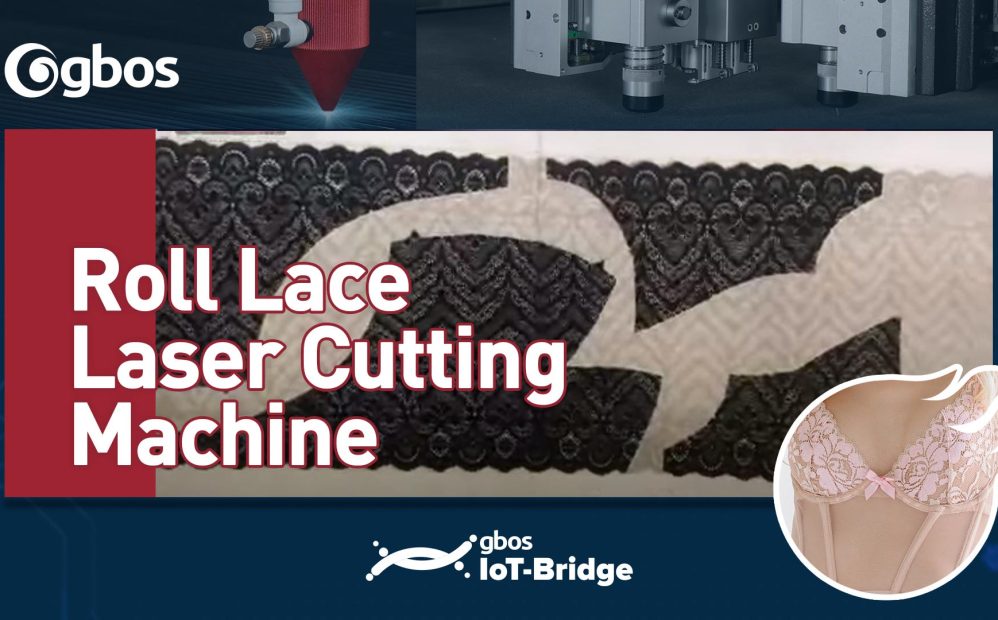

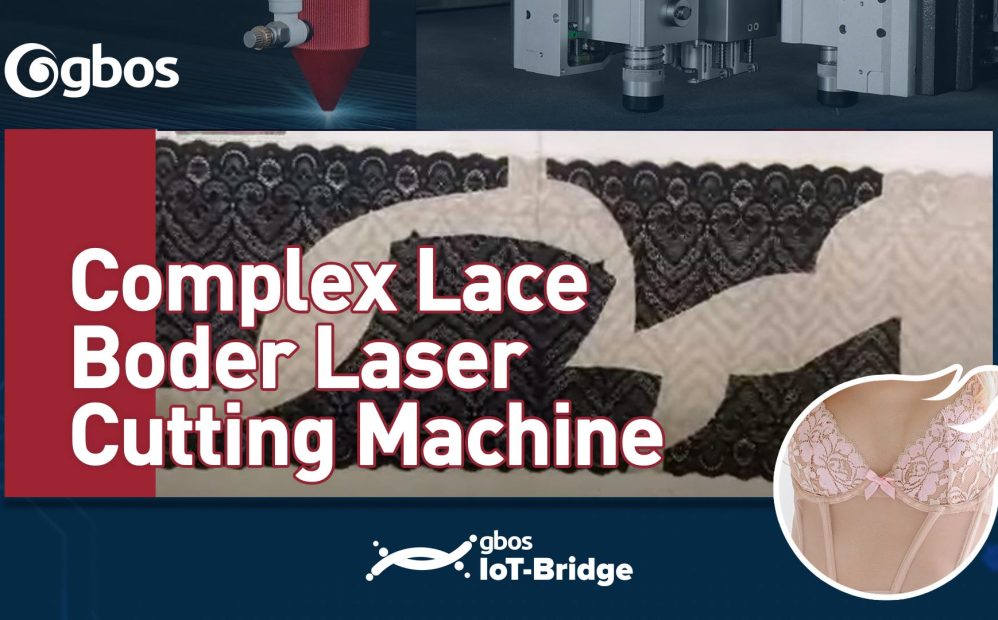

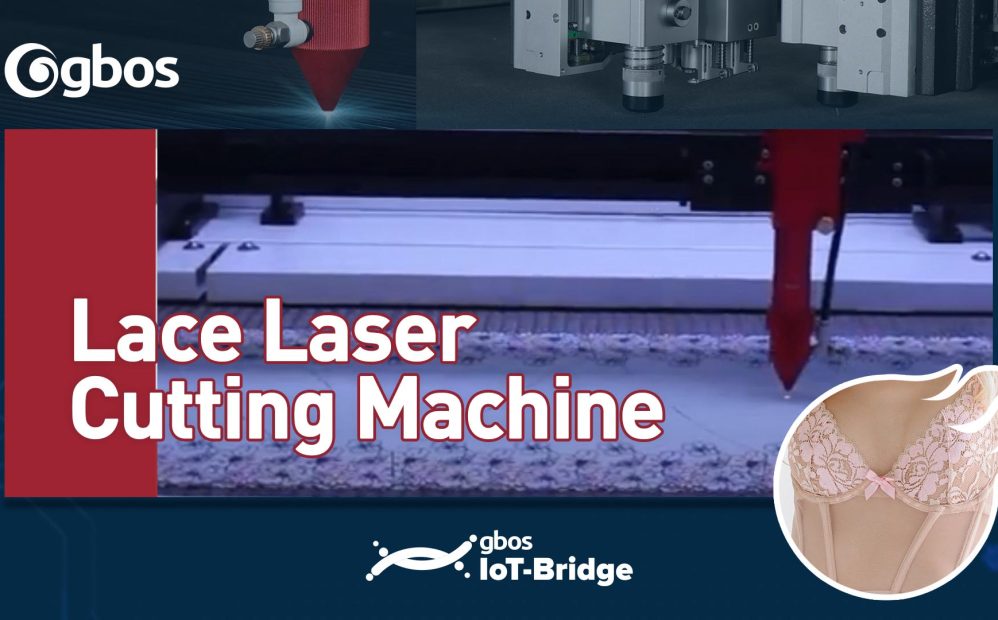

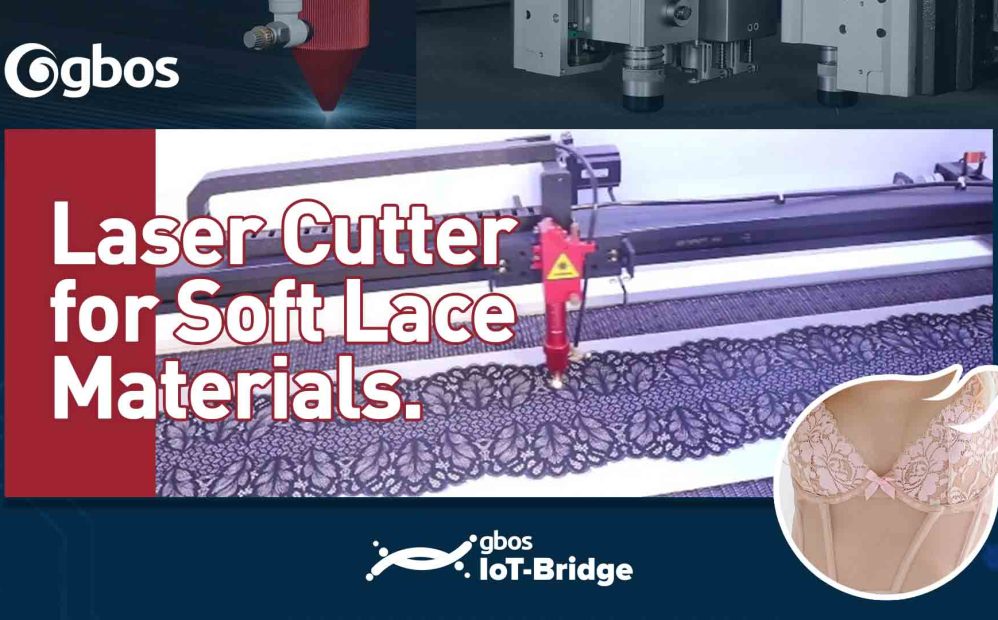

Overreliance on manual labor in traditional lace cutting has resulted in issues of inconsistency and substandard quality in the products. This not only impacts the appearance and comfort of the products but also escalates the rate of defective items and production costs.

-

Advantages of GBOS Solutions

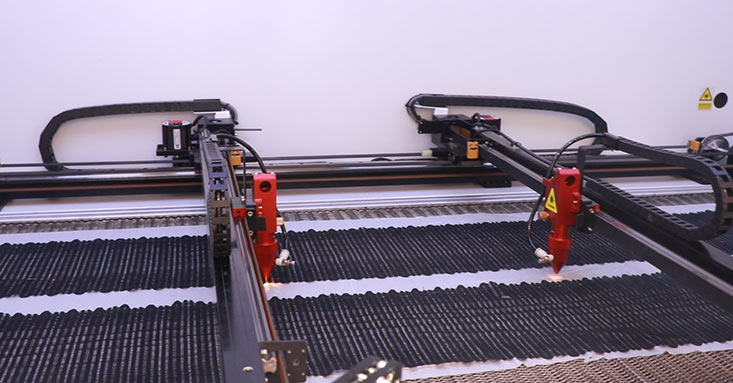

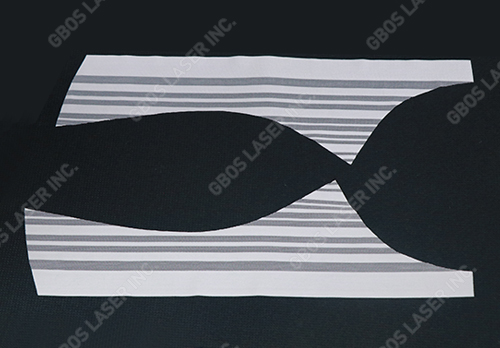

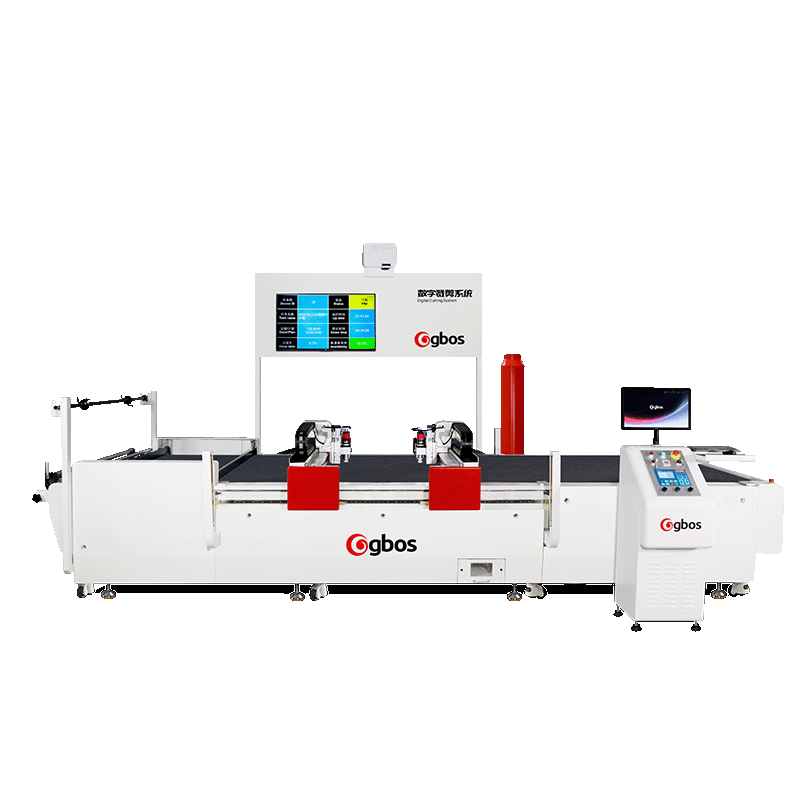

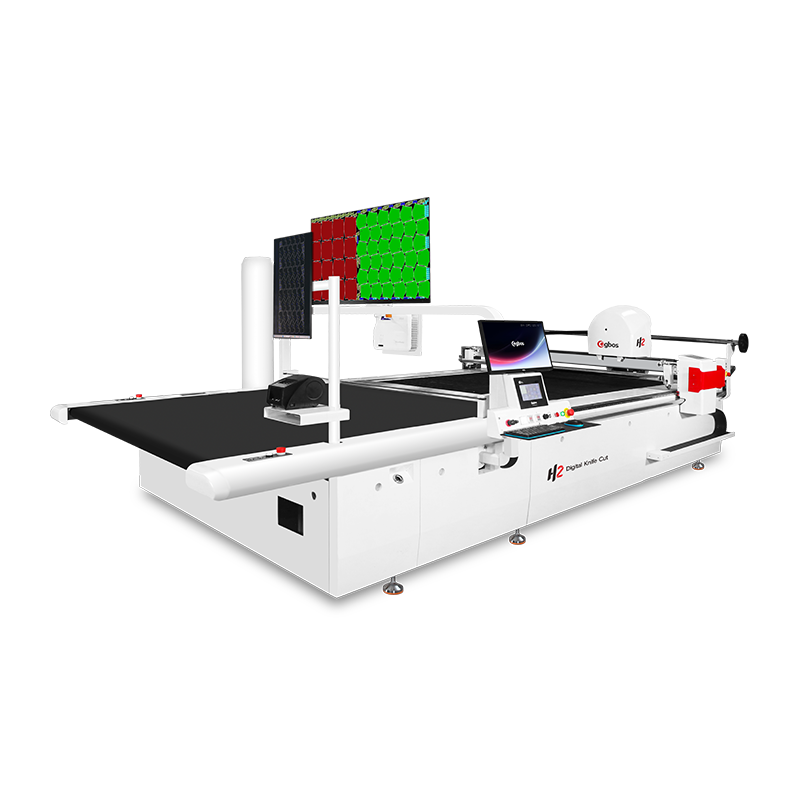

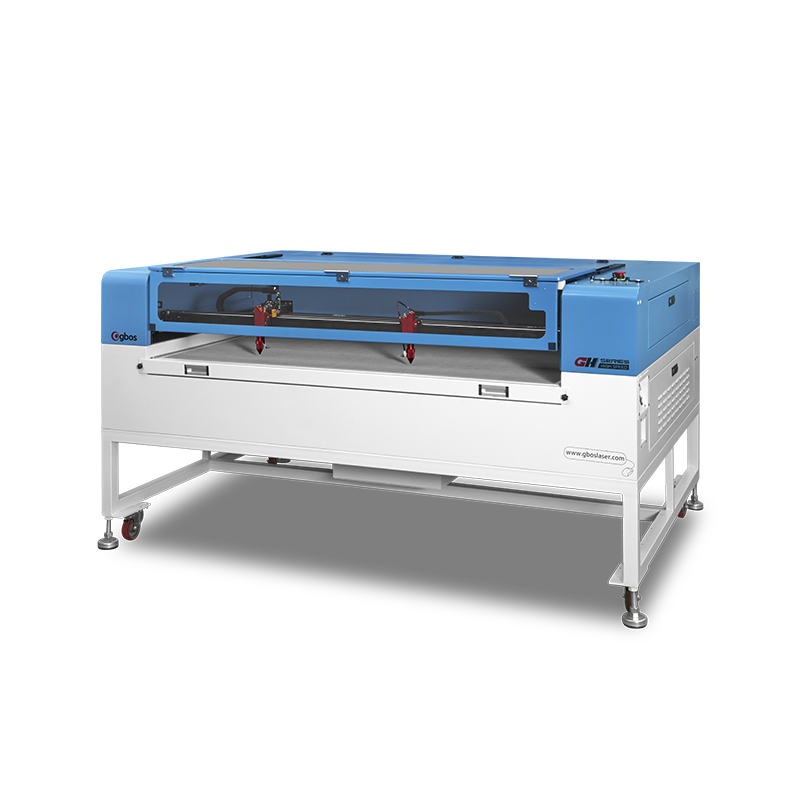

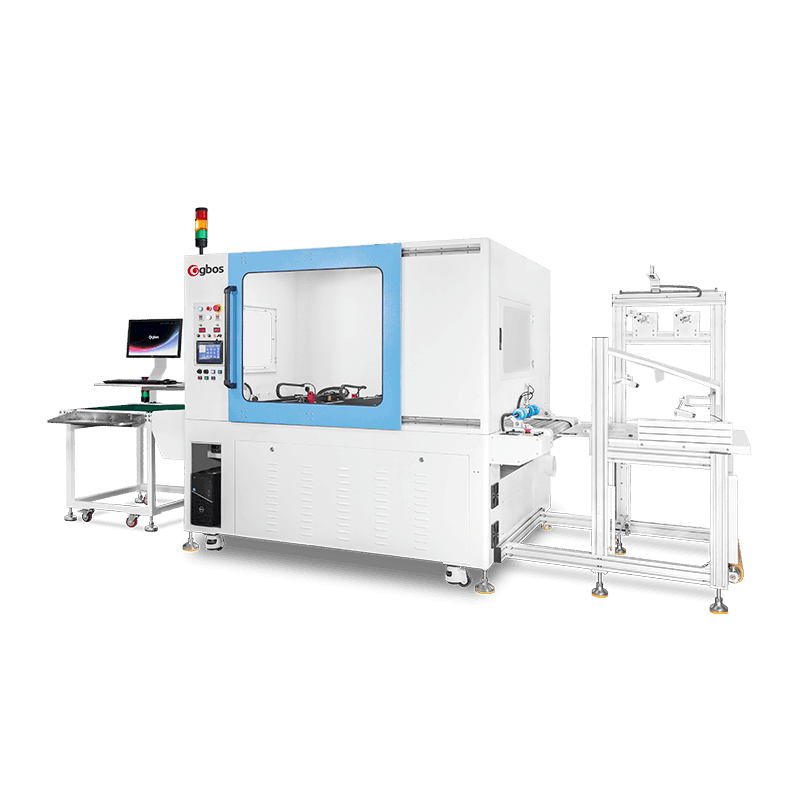

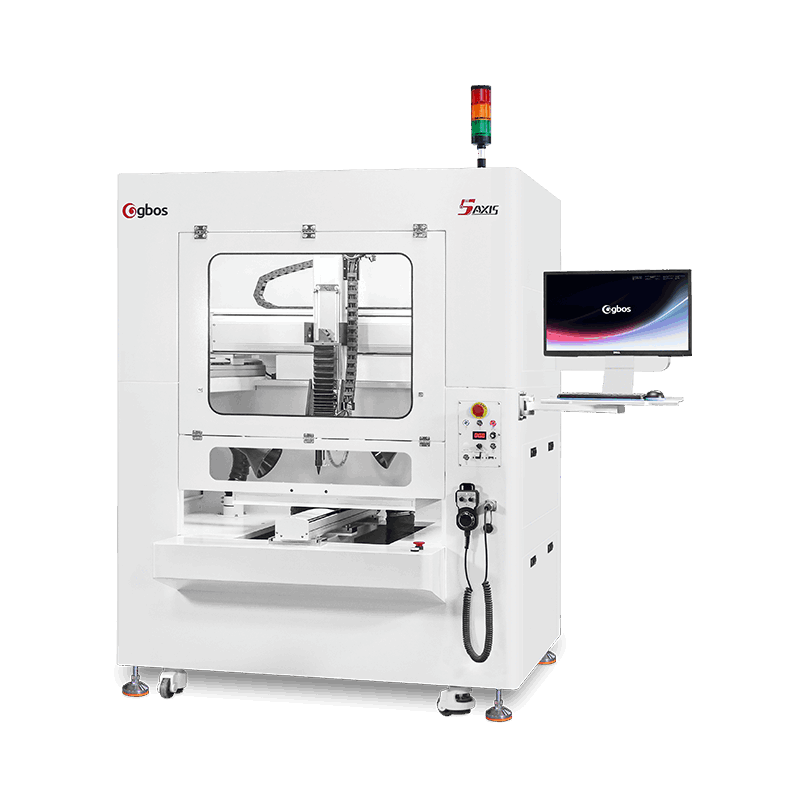

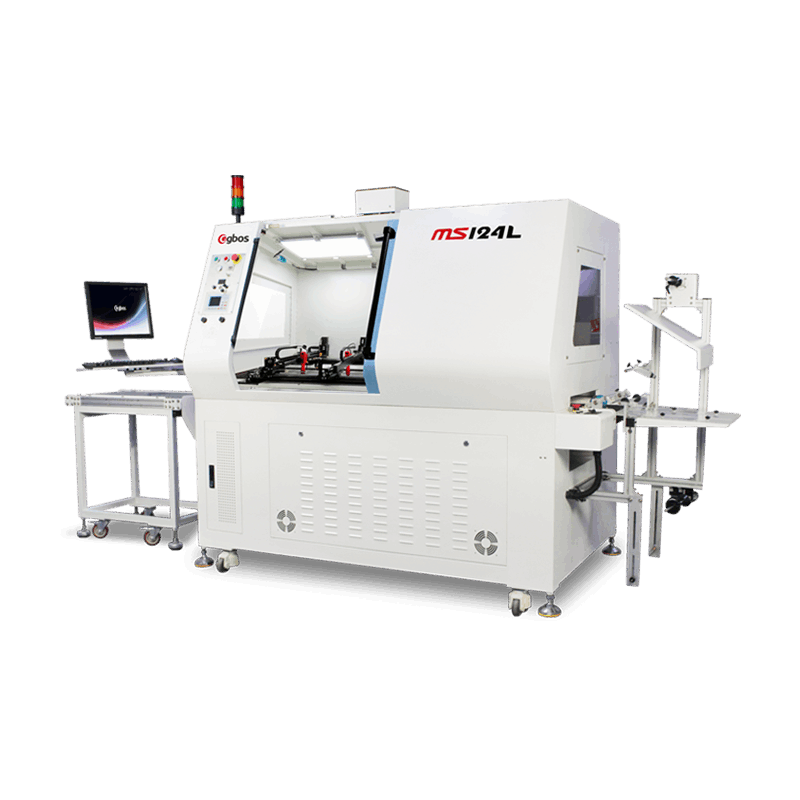

The modern AI SCCD VisionScan dual-head asynchronous lace laser cutting machine has emerged as an automated solution. It ensures cutting precision within ±0.01mm while guaranteeing product consistency, thereby significantly enhancing production efficiency, reduce production process, reduce material waste and save labor, realize factory automation manufacturing.

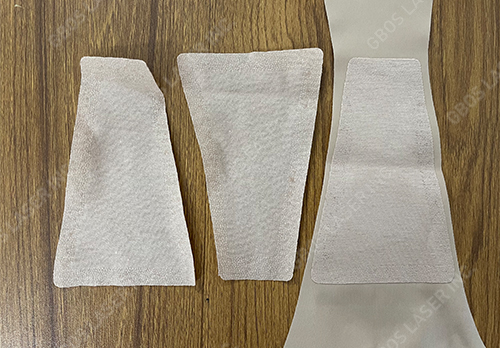

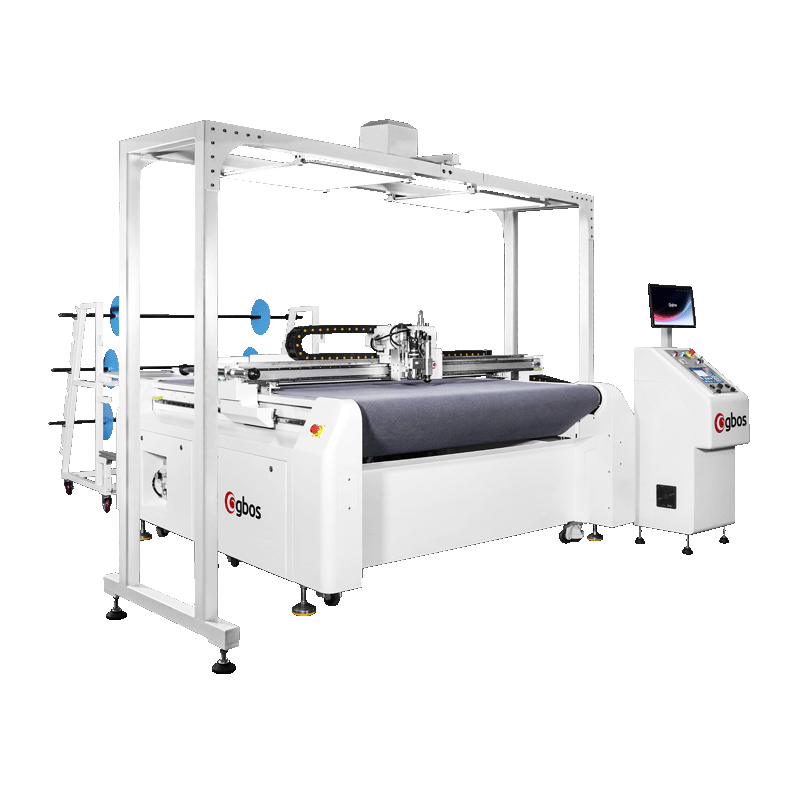

PUR dispensing + cutting all in one solution, reduce process, increase productivity, keep cloth comfortable.

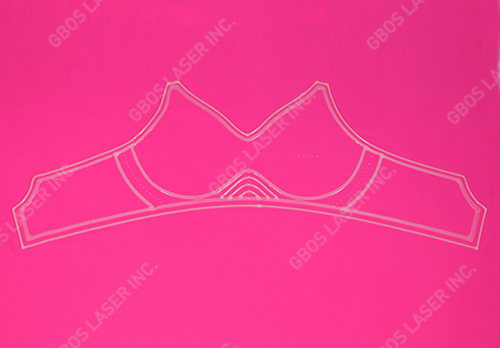

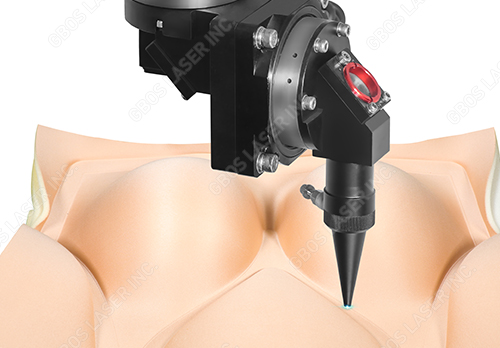

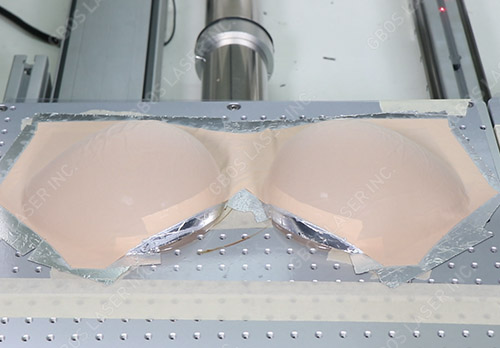

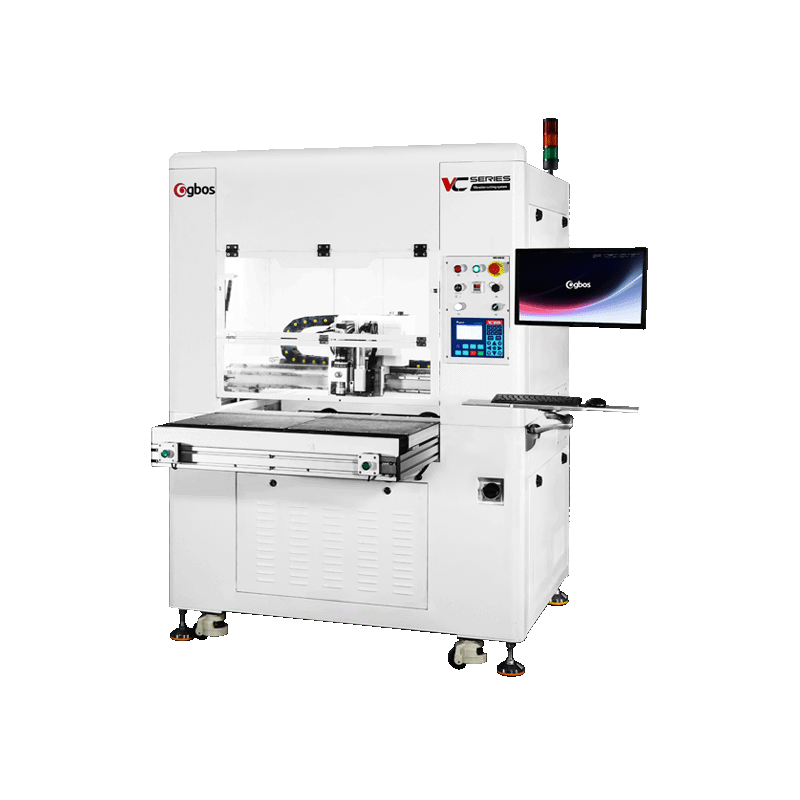

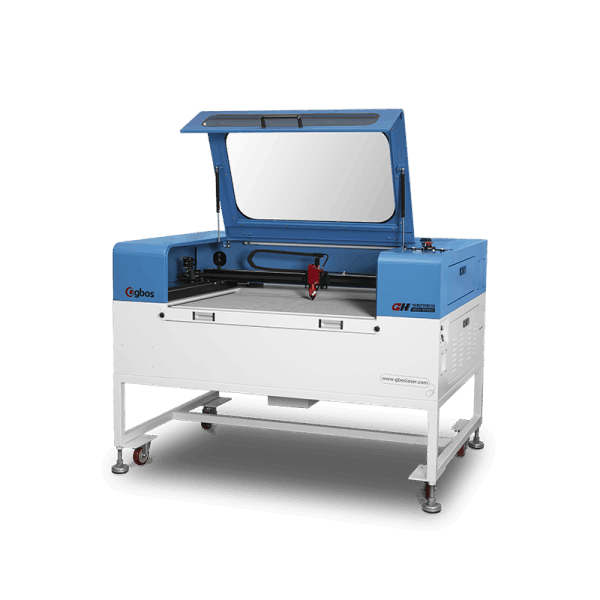

3D lingerie cup laser cutting, no yellow edges, no burnt edges.

- Lace Laser Cutting Solution

- Lingerie Laser Cutting Solution

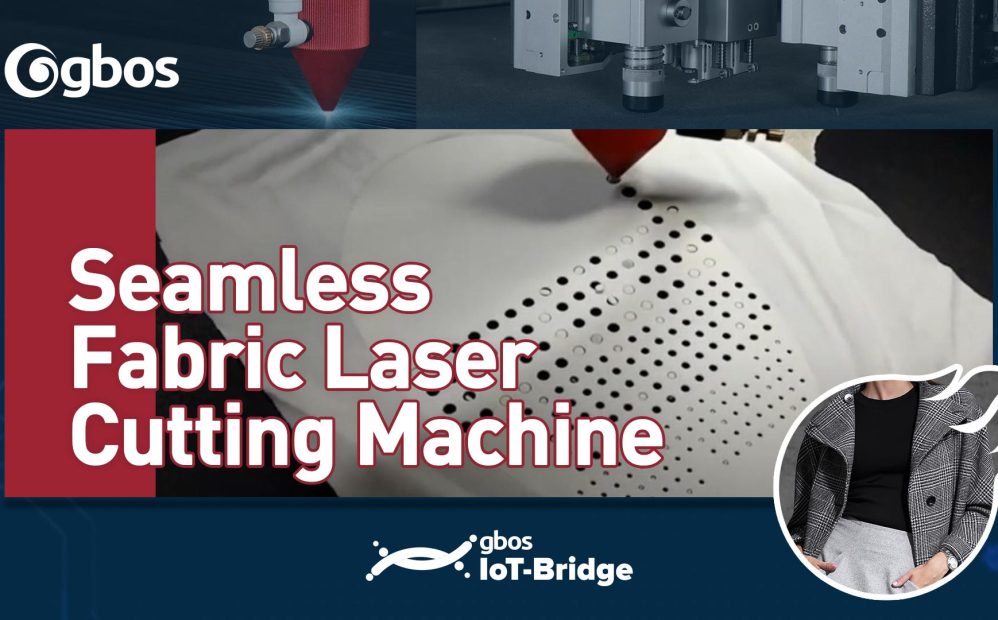

- Sewfree® Fabric Laser Cutting Solution

- (Sewfree®) Lingerie PUR Dispensing Solution

- Lingerie Laser Perforating Breathable Hole Solution

- 3D Bra Cup Laser Cutting

-

Oct 16,2025In the apparel manufacturing industry, Sewfree technology is rapidly emerging as a new favorite thanks to its unique advantages. From comfortable seamless underwear to performance-enhancing sportswear, and from weather-resistant jackets to breathable quick-dry T-shirts, Sewfree applications are becoming increasingly widespread—winning the favor of global consumers. Consumers favor Sewfree garments primarily for their exceptional wearing experience. The seamless design eliminates the friction and discomfort caused by traditional stitches, allowing greater freedom of movement during daily wear or intense activities. It also enhances the garment’s overall aesthetics with smooth, minimalist lines that exude modern style. Moreover, the Sewfree structure improves durability by reducing seam wear and tear, extending the garment’s lifespan. However, in the front-end cutting process of Sewfree production, hot melt adhesive film cutting has become a major challenge for many manufacturers. Limited by traditional cutting technologies, numerous factories struggle with low cutting efficiency and serious material waste. Although laser cutting machines are sometimes used, their inherent laser characteristics allow cutting only one layer per pass. For enterprises focused on mass production and fast delivery, this single-layer cutting mode significantly restricts lead times and undermines market competitiveness. Against this backdrop, GBOS, backed by deep technical expertise and a spirit of innovation,...

-

Jun 25,2025As summer temperatures soar, swimming is emerging as one of the hottest summer trends for cooling off and staying active. Market data shows a steady rise in sales of swim-related products, with swimwear in particular riding the wave of consumer demand. Surging Swimwear Demand Amid the Summer Economy Boom As an essential piece of swim gear, swimwear continues to experience growing market demand. Today’s consumers are no longer satisfied with basic functionality alone—they are increasingly seeking the perfect blend of fashion, comfort, and personalization. This evolving trend presents unprecedented challenges for swimwear manufacturers. Challenges and Bottlenecks Facing Swimwear Manufacturers Despite the surging market demand, swimwear manufacturers find themselves caught in a difficult dilemma. On one hand, traditional manufacturing processes struggle to handle elastic fabrics efficiently, often falling short in achieving precise cutting. This lack of accuracy leads to significant material waste. According to industry data, cutting errors in conventional production methods contribute to substantial fabric loss—undeniably driving up overall manufacturing costs. On the other hand, as consumer demand for personalized swimwear continues to rise, manufacturers are forced to frequently adjust their production processes to accommodate various styles and patterns. This constant adaptation significantly reduces production efficiency and extends lead times,...

-

Feb 21,2025As the festive buzz of the Spring Festival fades, it leaves behind not only cherished memories of reunion but also a few extra pounds around the waist. With fitness resolutions in full swing, people are sweating it out to kickstart a healthier year. This workout boom has undoubtedly created a surge in demand for sports lingerie, with orders rising like spring bamboo shoots. However, amidst this promising outlook, can manufacturers truly stand out? 01 The Sports Bra Market is Booming, but Manufacturers Face Growing Challenges As health awareness deepens, exercise has become an essential part of daily life. sports lingerie, crucial for comfort and support during workouts, continue to see rising demand. Especially in the post-holiday period, a surge in fitness activities has led to an explosion in orders. However, behind this booming market, manufacturers face significant production challenges. ① Multi-Layer Material Cutting Challenges: Balancing Efficiency and Quality Sports bras require multiple fabric layers, but cutting them poses a challenge. Traditional methods struggle with low precision, high material waste, and slow speed, making it hard to meet demand. Cutting Lycra and seamless fabrics is especially tricky—any slight misstep can lead to uneven edges, deformation, or overcutting, impacting product quality and...

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: