In the apparel manufacturing industry, Sewfree technology is rapidly emerging as a new favorite thanks to its unique advantages. From comfortable seamless underwear to performance-enhancing sportswear, and from weather-resistant jackets to breathable quick-dry T-shirts, Sewfree applications are becoming increasingly widespread—winning the favor of global consumers.

Consumers favor Sewfree garments primarily for their exceptional wearing experience. The seamless design eliminates the friction and discomfort caused by traditional stitches, allowing greater freedom of movement during daily wear or intense activities. It also enhances the garment’s overall aesthetics with smooth, minimalist lines that exude modern style. Moreover, the Sewfree structure improves durability by reducing seam wear and tear, extending the garment’s lifespan.

However, in the front-end cutting process of Sewfree production, hot melt adhesive film cutting has become a major challenge for many manufacturers. Limited by traditional cutting technologies, numerous factories struggle with low cutting efficiency and serious material waste. Although laser cutting machines are sometimes used, their inherent laser characteristics allow cutting only one layer per pass. For enterprises focused on mass production and fast delivery, this single-layer cutting mode significantly restricts lead times and undermines market competitiveness.

Against this backdrop, GBOS, backed by deep technical expertise and a spirit of innovation, launched the VC9-1612 Intelligent Oscillating Knife Cutting System — a digital blade cutting solution specifically designed for hot melt adhesive film cutting. This system delivers a perfect solution for multi-layer hot melt film cutting, redefining efficiency and precision in Sewfree manufacturing.

01 Multi-layer Hot Melt Film Cutting — A Leap in Efficiency

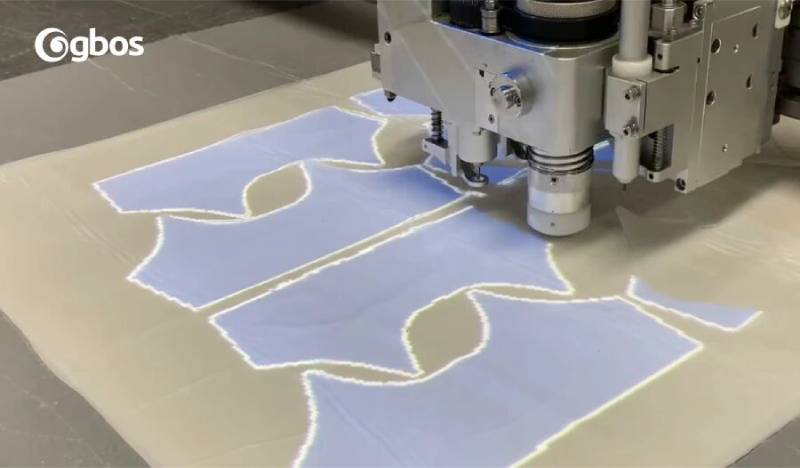

The VC9-1612 Intelligent Oscillating Knife Cutting System offers powerful multi-layer cutting capabilities, enabling simultaneous cutting of up to 12 layers of hot melt adhesive film in a single pass. Compared with the single-layer cutting mode of traditional laser machines, it significantly increases throughput within the same time frame, achieving a quantum leap in production efficiency. Moreover, the cut edges are smooth and clean, perfectly meeting the seamless bonding requirements of high-density smooth fabrics, ensuring superior garment quality.

02 Say Goodbye to Cutting Misalignment — Enjoy Worry-free Precision Positioning

In traditional apparel manufacturing, manual alignment and marking were indispensable steps — yet time-consuming, labor-intensive, and prone to human error, often compromising garment quality and consistency. The VC9-1612 eliminates these challenges by performing multiple processes independently without the need for multiple machines, making it adaptable to various production categories. It is equipped with projection positioning, an optional pen plotting device, and an intelligent nesting system, ensuring precise alignment, material efficiency, and seamless workflow integration.

The projection positioning system accurately projects designs onto the material, enabling fast and precise alignment. The optional pen plotting device assists in marking, providing accurate guidance for the next process. Meanwhile, the intelligent material-saving nesting system automatically optimizes layouts based on the material’s size and shape, minimizing waste and maximizing efficiency.

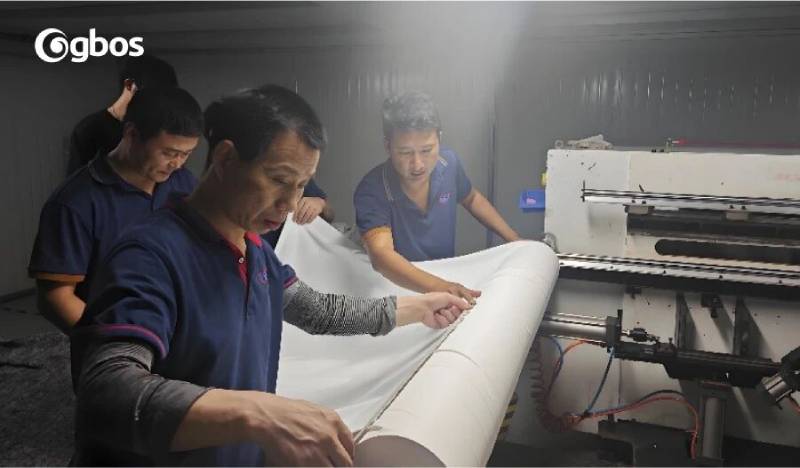

(Image from customer site,Wheel knife cutting device)

Take sportswear production as an example: precise positioning and layout ensure that every garment part maintains accurate dimensions and shapes, enhancing the fit and comfort of the finished sportswear.

03 Empowering Apparel Manufacturers to Optimize Production and Achieve Holistic Growth

As Sewfree technology becomes increasingly widespread in the apparel industry, the performance of production equipment plays a critical role in achieving optimal results. The VC9-1612 enhances efficiency through multi-layer cutting and ensures precision with its projection positioning system, delivering significant improvements in production capacity, quality control, and cost management for apparel manufacturers.

In terms of production capacity, the highly efficient multi-layer cutting capability enables manufacturers to complete more tasks in less time, meeting the rapidly growing market demand for Sewfree garments.

In terms of quality control, precise positioning and cutting ensure consistent garment quality, reduce defect rates, and enhance brand reputation.

In terms of cost control, the intelligent material-saving nesting system effectively reduces material waste, improves equipment utilization, and lowers overall production costs.

For outdoor jacket manufacturers, the optimized production process enhances efficiency, ensures product quality, and reduces production costs, giving companies a competitive edge in a highly challenging market.

With the support of the VC9-1612, Sewfree garments are set to shine even brighter in the market, offering consumers more high-quality and comfortable wearing options.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: