Stock Code: 870145

Green Manufacturing, Create Green Future

Empowering the Goal of "Carbon Neutrality, Carbon Peaking".

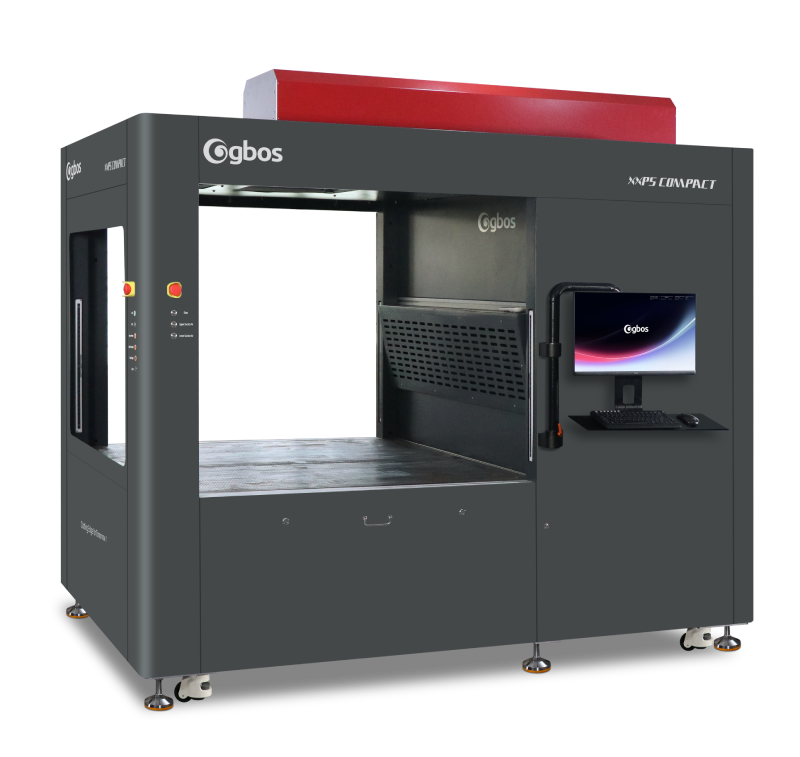

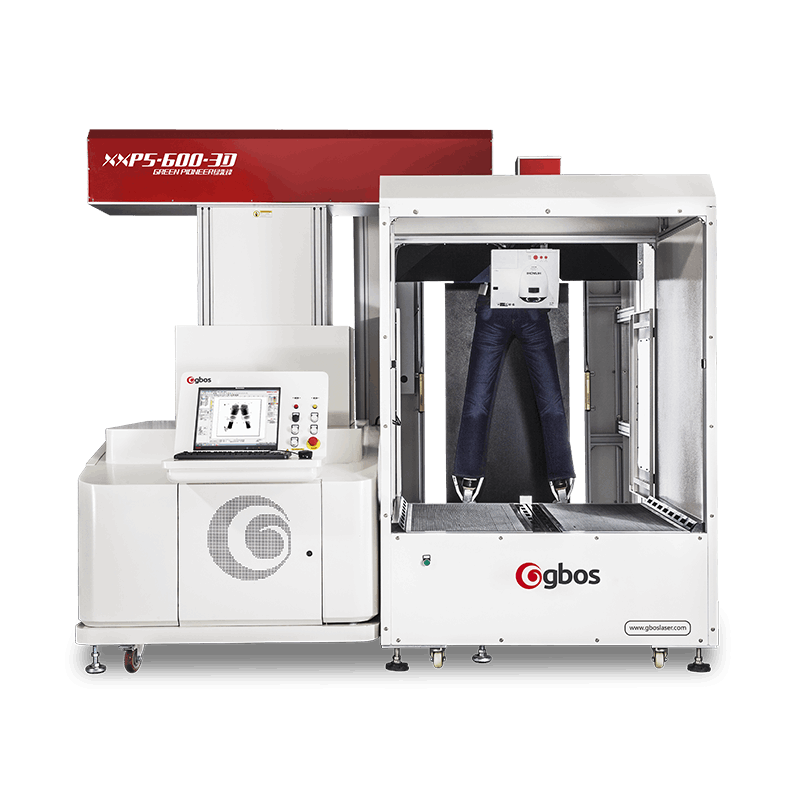

Home > Product Center > Laser Denim Finishing Systems

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

- GBOS Global Headquarters

-

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Tel: +86 769 88990609

Fax: +86 769 88990677

Email: gbos@gboslaser.com

© 2024 GBOS.All Rights Reserved.

Privacy Policy|Site Map

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: