Stock Code: 870145

Green Pioneer XXP5-600 Series

CO2 Laser Denim Finishing System

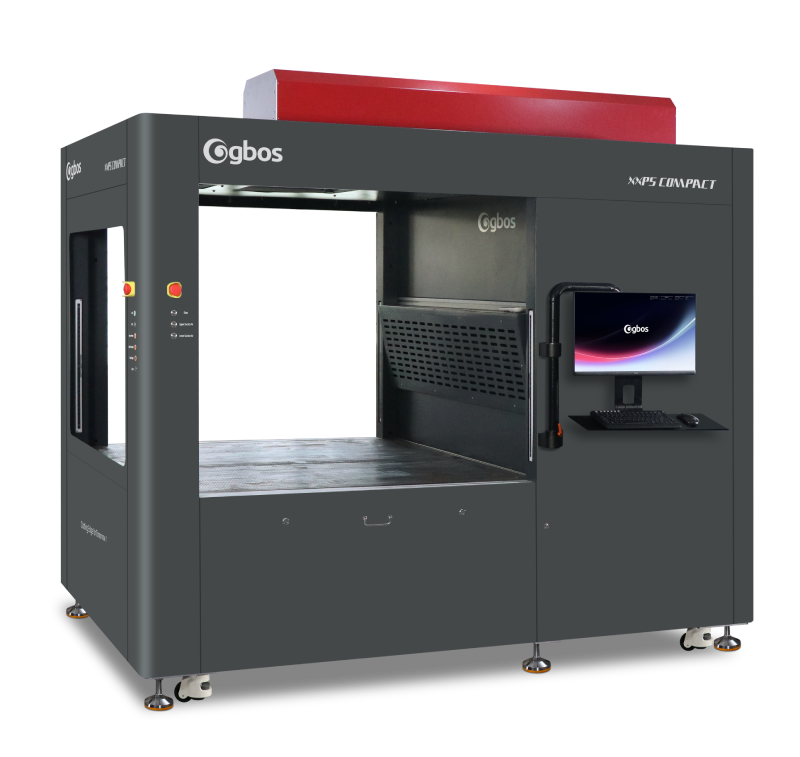

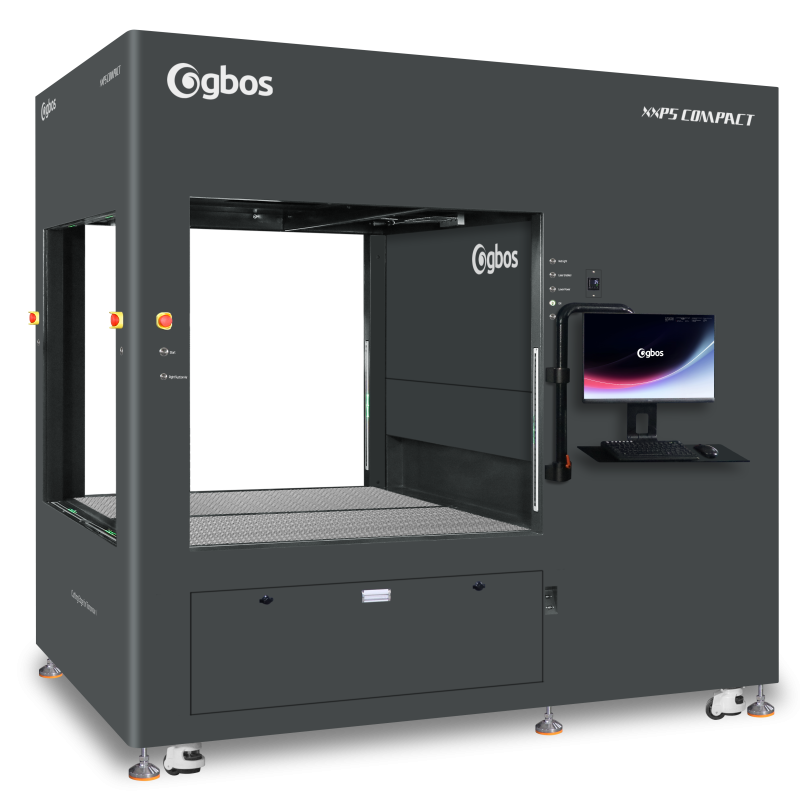

The compact nature of the machine makes it ideal for smaller workshops or factories where space is limited.The three-sided open design, combined with a safety light curtain system, makes denim washing operations more convenient and efficient.

Working area: 1300*1300mm.

Compact in Size. Unlimited in Power.

A space-efficient design for higher productivity.

Powered by Luxinar Laser Technology(UK).

Specifications

Model

Description

Industry application

Modules

Working area

Whole power

Laser power

System requirements

Power supply

Product dimensions

Weight

Custom

Product Function

-

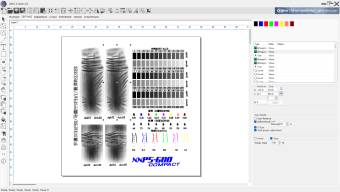

S-Denim 6.0 SystemInfinite Possibilities in Denim Dry Processing. Built-in extensive creative cloud library, enabling real-time effect preview and parameter adjustment, with a clean, intuitive interface for seamless operation.

-

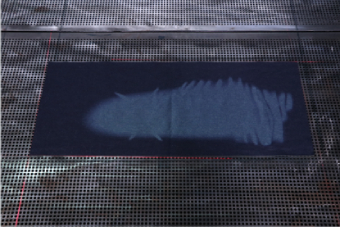

Demonstration of Multiple Process EffectsA single machine is capable of performing various denim washing processes, including "Laser Ripping, Laser Grinding, Pp Spray Simulation, Laser Whiskers, All-over Laser Marking". It is both efficient and eco-friendly, significantly enhancing production efficiency.

-

Projection Preview Positioning SystemThrough a high-definition projection system, the denim washing processes are clearly projected onto the denim fabric, allowing for an intuitive view of the process effects.

-

Red Light Preview Positioning DeviceEquipped with four high-precision infrared ray devices, the emitted red light can clearly locate the placement positions of fabric cut-pieces, effectively avoiding placement deviations and ensuring the smoothness and precision of the production process.

-

Compact Open-style WorkbenchThe overall size of the workbench is compact, saving space. With a three-sided open design, it offers a wide field of view and convenient operation. It is suitable for both denim fabric cut-pieces and supports direct washing of finished denim garments, meeting diverse production requirements.

-

3D Air Suction DeviceIt is equipped with a built-in multi-dimensional air suction module that can absorb and exhaust work-related fumes in real time. It provides full coverage of the screen and sides of the work area, safeguarding the environment and the health of operators.

-

Active Cooling (AC) System(Optional)Integrated air-cooling system for laser source stability and long-term reliability.

Expand More +

Functions & Modules

-

Utilizes infrared laser projection to precisely locate fabric cut pieces in real-time, enabling error-free alignment during material handling.More Details

-

Projects full-scale visual simulations of denim washing treatments onto the work area in real time, enabling instant verification of pattern alignment and effect accuracy.More Details

-

Purify and treat the smoke and waste gas generated during the cutting processMore Details

-

By utilizing the convective heat transfer effect of the circulating water inside the water tank, stable control over the heat generated during the operation of the laser tube is achieved.More Details

Expand More +

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: