Stock Code: 870145

ITS2/3/5 Series

AI VisionScan Leather Nesting System

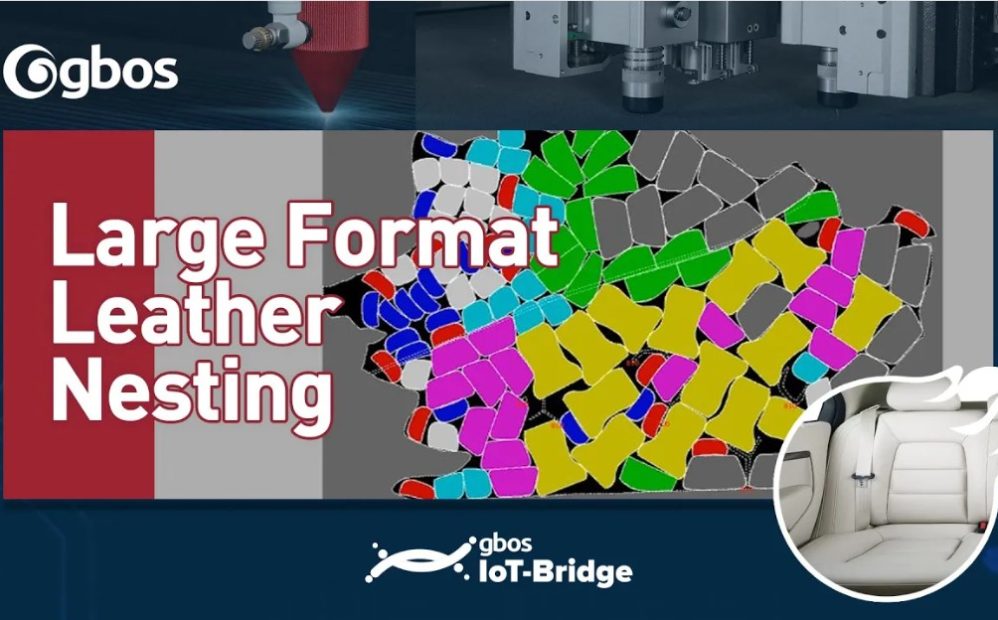

Leading AI leather nesting algorithm codes increase leather utilization rate, provide user-friendly experience, and unlock the full value of every inch of leather.

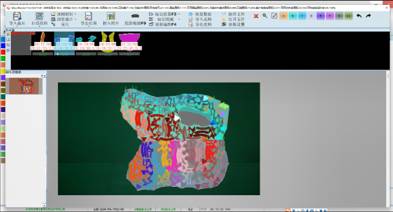

AI automatic nesting function.

Users can manually intervene in the layout results.

Equipped with defect detection and utilization functions.

Supports partitioning, pairing, and simultaneous nesting of multiple leather pieces.

Supports automatic counting function and can be combined with oscillating knife series systems and laser cutting systems.

Specifications

Model

Description

Industry application

Modules

Working area

Whole power

Laser power

System requirements

Power supply

Product dimensions

Weight

Custom

Product Function

-

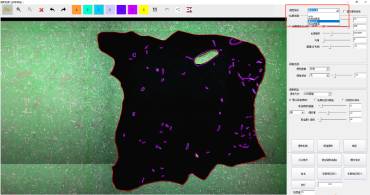

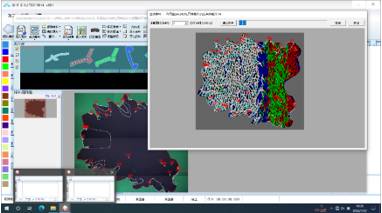

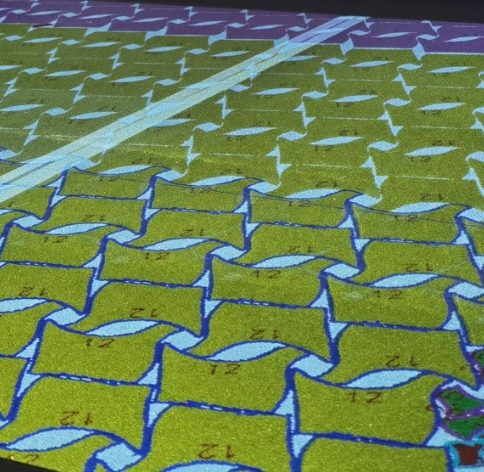

GBOS New Deep Learning Large ModelThe system self-purifies, becoming smarter with use. It automatically identifies leather defects, adapts to different colors and markings, significantly boosting efficiency while saving manpower and time.

-

Two High-definition Industrial Cameras40 million pixels, with wider recognition accuracy and range.

-

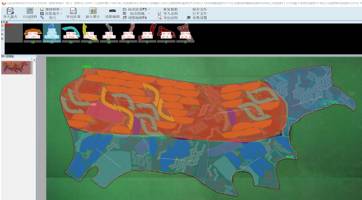

Cardboard Matching LayoutFor fur-integrated materials, nesting can be done through cardboard matching.

-

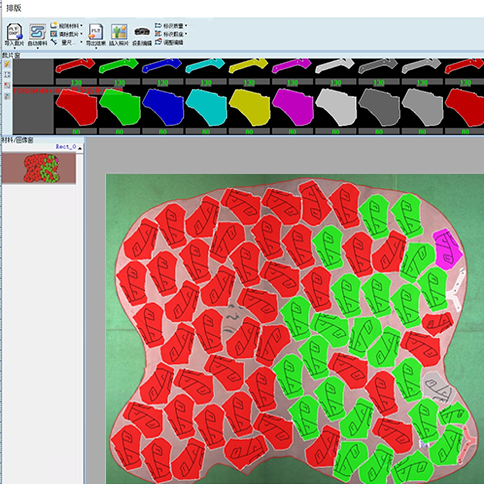

Double Color MatchingTypographyDifferent pieces are configured with different colors for distinction, and paired according to the piece data, improving work efficiency.

-

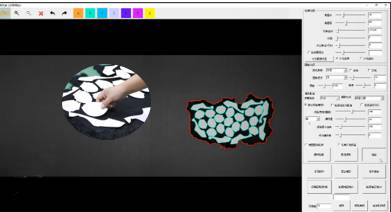

Multi-task OperationIn the same interface, multiple leather pieces can be photographed and nested simultaneously.

-

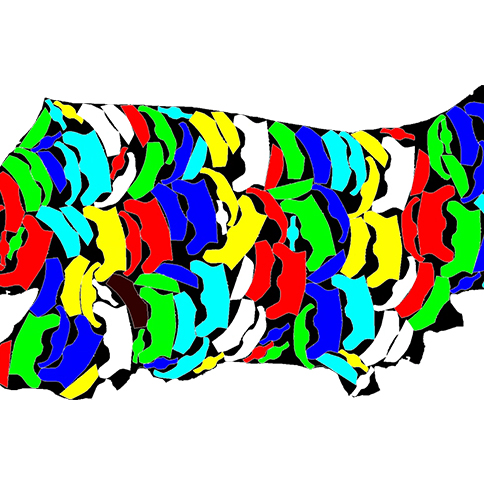

Nesting in Hair DirectionFor hairy materials, nesting can be performed based on the direction of the hair.

-

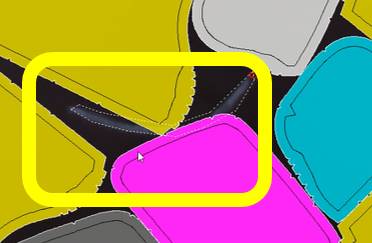

Overlay TypographyWithin the quality acceptance range, it achieves compatibility, knife eating, and improves utilization.

-

Utilization of DefectsAutomatically arranges areas that can be hidden by stitching in flawed regions.

Expand More +

Functions & Modules

-

Intelligent nesting for genuine leather, automatically identifies defects, optimizes the cutting area of the leather, increases utilization, and reduces material waste.More Details

-

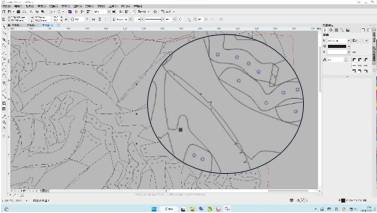

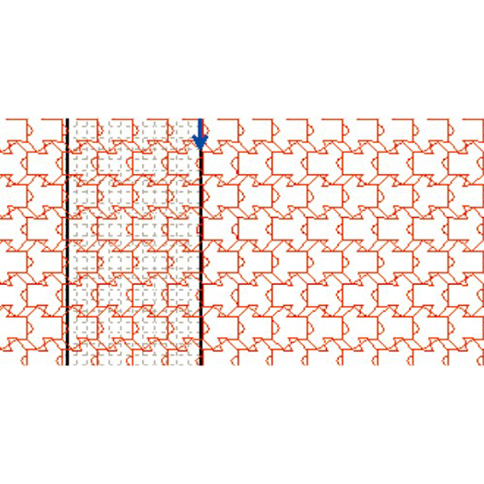

Intelligent nesting system, which is used for regular materials and can improve utilization and reduce material waste.More Details

-

Achieve digital management, reduce paper-oriented work, empowering “Carbon Neutral” goals.More Details

-

The code management system can automatically recognize and read barcodes and QR codes on leather materials, thereby achieving automatic management of materials.More Details

-

Real-time preview of nesting result, convenient and fast. Real-time nesting, manual insert, maximize material utilization rate.More Details

Expand More +

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: