Stock Code: 870145

Green Pioneer XXP5-AW Series

CO2 Laser Denim Finishing System

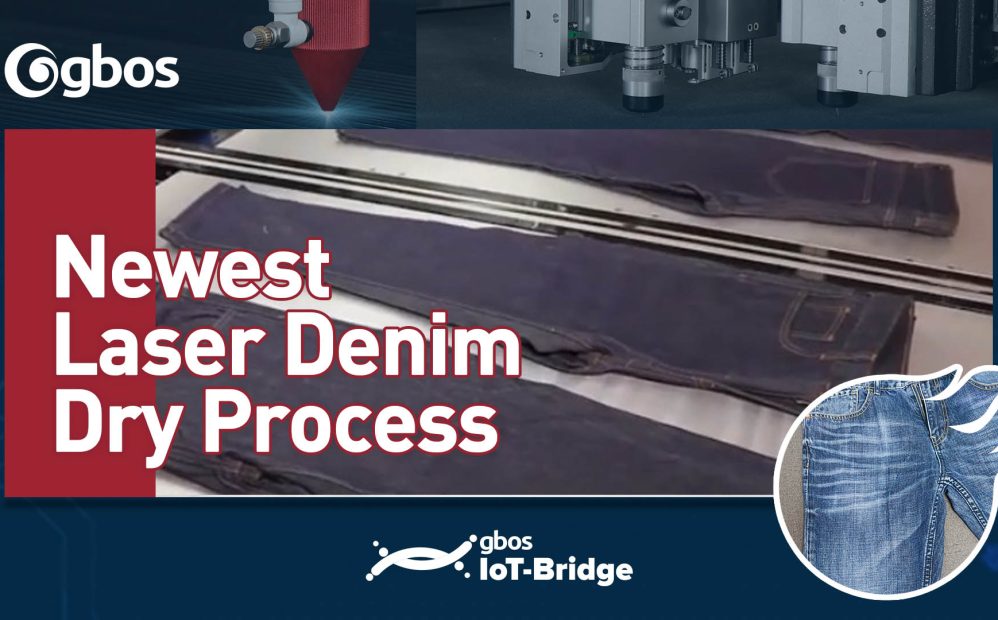

The Preferred High Speed Model for Jeans and Mass Production

High dynamic range imaging.

Washing water digital technology 6.0.

Double-station interactive work platform.

Specifications

Model

Description

Industry application

Modules

Working area

Whole power

Laser power

System requirements

Power supply

Product dimensions

Weight

Custom

Product Function

-

“Cloud” Support, Sharing Idea with Whole WorldProvide massive design resources, solve design requirements of users, boost massive saving in design costs and time.

-

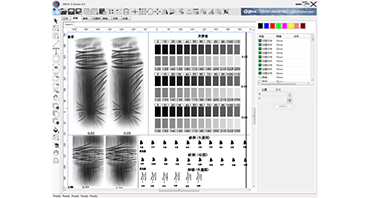

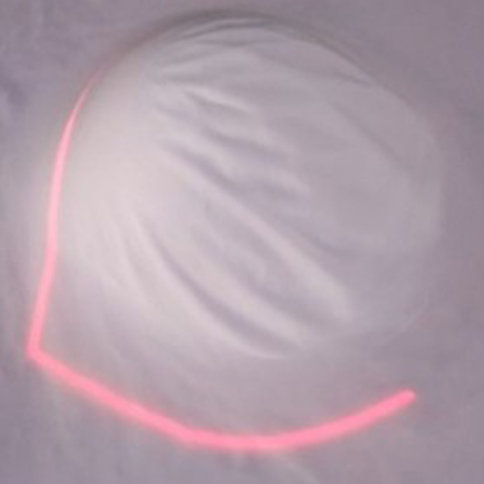

S-HDR, the Key Technology for Clear, Three-dimensional, Delicate and NaturalOver-motion range imaging laser technology, the images are clear, detailed and realistic. Also, makes the dark texture and shadow details perfectly presented.

-

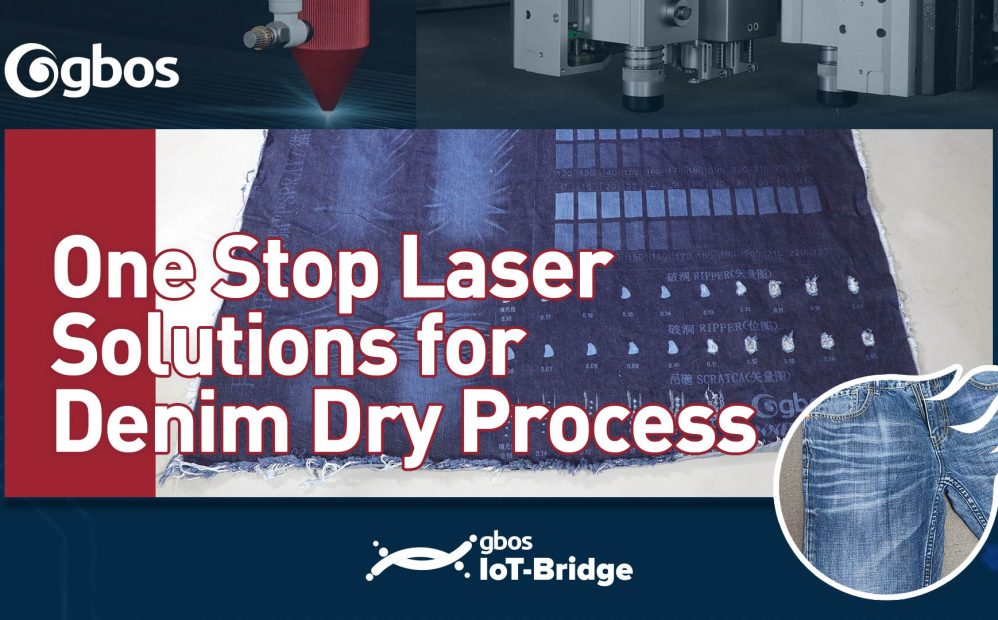

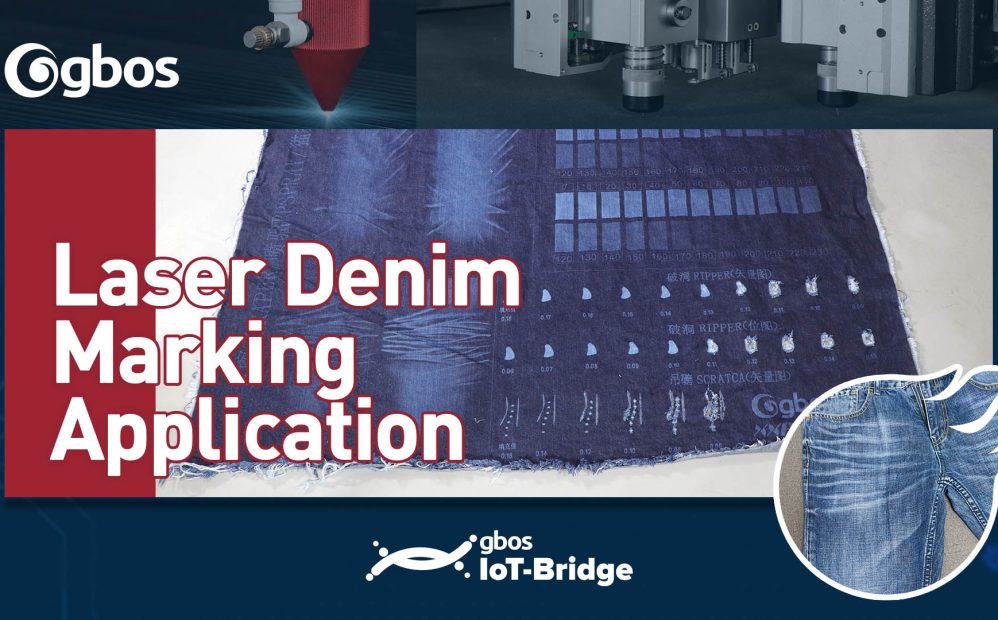

Pay Respect to Traditional Craftsmanship with Digital TechnologyIt has a natural sense like traditional crafts, with clear and delicate layering, different fashion styles can be created. (China, Japan & Korea Style: Minimalist, fresh and natural; Western style: Wild and bold.)

-

Process 6.0, Increase Capacity and Efficiency while Achieving CustomizationDestroy effect 5 seconds/2 legs; Cat whisker, Monkey wash 25 seconds/2 legs; Grinding effect 2 seconds/2 legs; Full Printing 3 minutes/2 legs.

-

Precisely Control of Process EffectsControllable parameters of weft strength; Arbitrary adjustment of partial deformation; Accurate adjustment of partial gray scale and intensity.

-

Ecology 6.0, to Promote Carbon Neutrality and Sustainable Development Strategies for EnterpriseProcess without chemical, working environment is guaranteed; Compared to traditional manual: No CO2 emission, contribute to achieving carbon neutrality targets.

-

The Whole Process is EasyOne-Click solution for denim washing process, no skill requirement for operator, no proficiency requirement, operate like cover your eyes.

-

Simulation Effect Preview and PositioningVisual simulation background and positioning; Projection simulation effect preview and positioning, convenient to identify, real-time presentation of process effects.

-

The Preferred Model for Jeans and Mass ProductionIntelligent interactive work, continuously working without waiting, front and back sides and multiple processes in one time! 30% faster than the 5th generation.

-

Executive StandardWith 3 Emergency stop switches, have safety isolation protection between loading & unloading area and laser processing area, 2 feeding operation switches, IP54 electric dust-proof design.

Expand More +

Functions & Modules

-

Real-time preview of nesting result, convenient and fast. Real-time nesting, manual insert, maximize material utilization rate.More Details

-

Purify and treat the smoke and waste gas generated during the cutting processMore Details

Expand More +

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: