On January 1, 2024, the 11th mini marathon of GBOS was officially kicked off in Dongguan Tongsha Eco Park! On that day, all GBOS staff and some customers and friends happily participated in it, giving a good start to the year 2024!

The warm-up began!

Move your hands, shake your shoulders,

Twist your waist and kick your legs

The energetic pre-game preparation

Unleashing infinite joy and enthusiasm

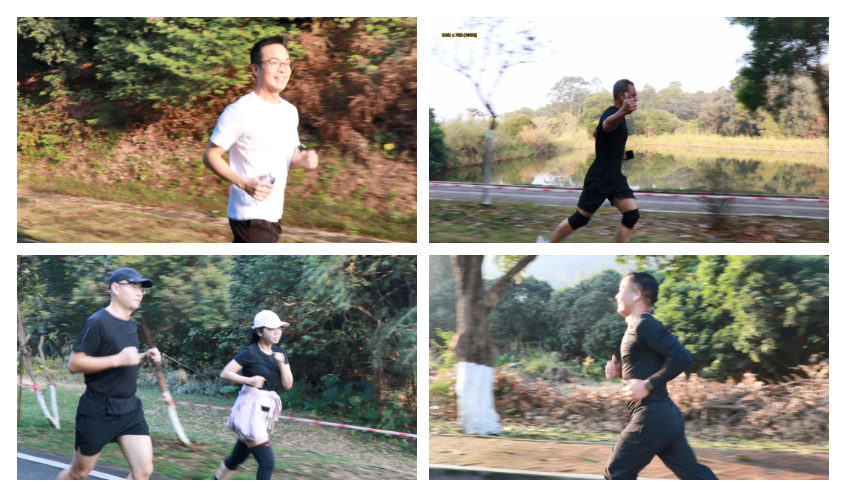

Strong posture

Bright smiling faces

The sound and shadow of running

Together, we built a beautiful landscape!

Our running figures can be seen all along the way

Confident steps, resolute eyes, joyful laughter

And an unshakable heart

We ran forward with all our might!

The spirit of the marathon is alive and well

Everyone steps in their own rhythm

Crossing the finish line

Breaking through the limit

Leaving an heroic posture in our wake

GBOS 2024 Marathon ended successfully

This event showed the new spirit of GBOS people

We are competing all the way and insisting all the way

Showing sunshine and vigor with speed

We wrote the struggle of youth with sweat

The first, second and third place winners

of the men’s and women’s categories came out at last!

We are full of energy

Applause rose and fell in succession

We promote friendship in the competition

Passing positive energy in sports

Taking photos under the warm sunshine

Record the new year look of GBOS!

With a dream in our heart

We keep on running

Embrace the light and run towards the future

GBOS never stops running!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: