The new era of intelligent manufacturing has arrived. Are you ready for the upcoming 2021? Give yourself a chance to occupy the market firstly and create a digital production workshop that integrates intelligence, automation and informatization.

A LIVE STREAM ON FACEBOOK!

Time: Fir Dec. 18th, 2020 10:10, GMT +0800

Aim to”More than just fast, faster than fast, breakthrough the last mile of smart cutting,” Let’s explore the cutting, line marking, punching, glue spray solutions together! And explore the cutting application together!

Show equipment

- VC9-1670T, Oscillating knife cutter, max cutting thickness: 18mm.

- GC850SCCD-P-EP, A machine for full-scene use, full-material use! Breakthrough the last mile of smart cutting.

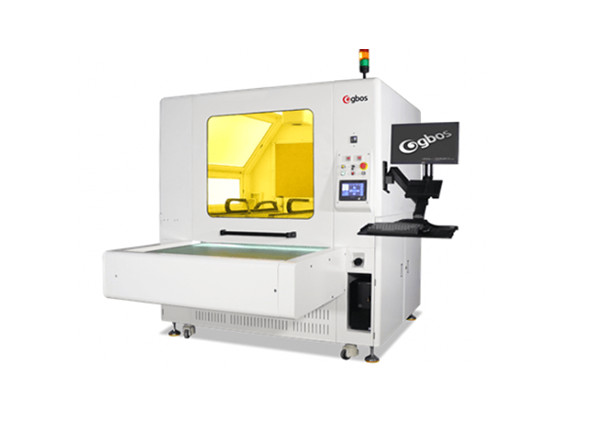

- XXP3.2-180-CCD, High speed laser marking machine.

- V10SCCD, SCCD for contour extracting and cutting digital printing shoe upper.

- R3, Smart Spray glue systems for shoe.

- LA-GN1280TT-SCCD-AT, Double head async 5G smart auto marking line machine.

- ITS2, Smart nesting system.

- VC9-1612, Small order, sample model.

Provide you fully a set of automatic solutions, and help your shoe factory enter Industry 4.0 before 2021! Help you enter smart die-less cutting; Inputting pattern, cutting, feeding, collecting, calculating all in one; Customized and more!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: