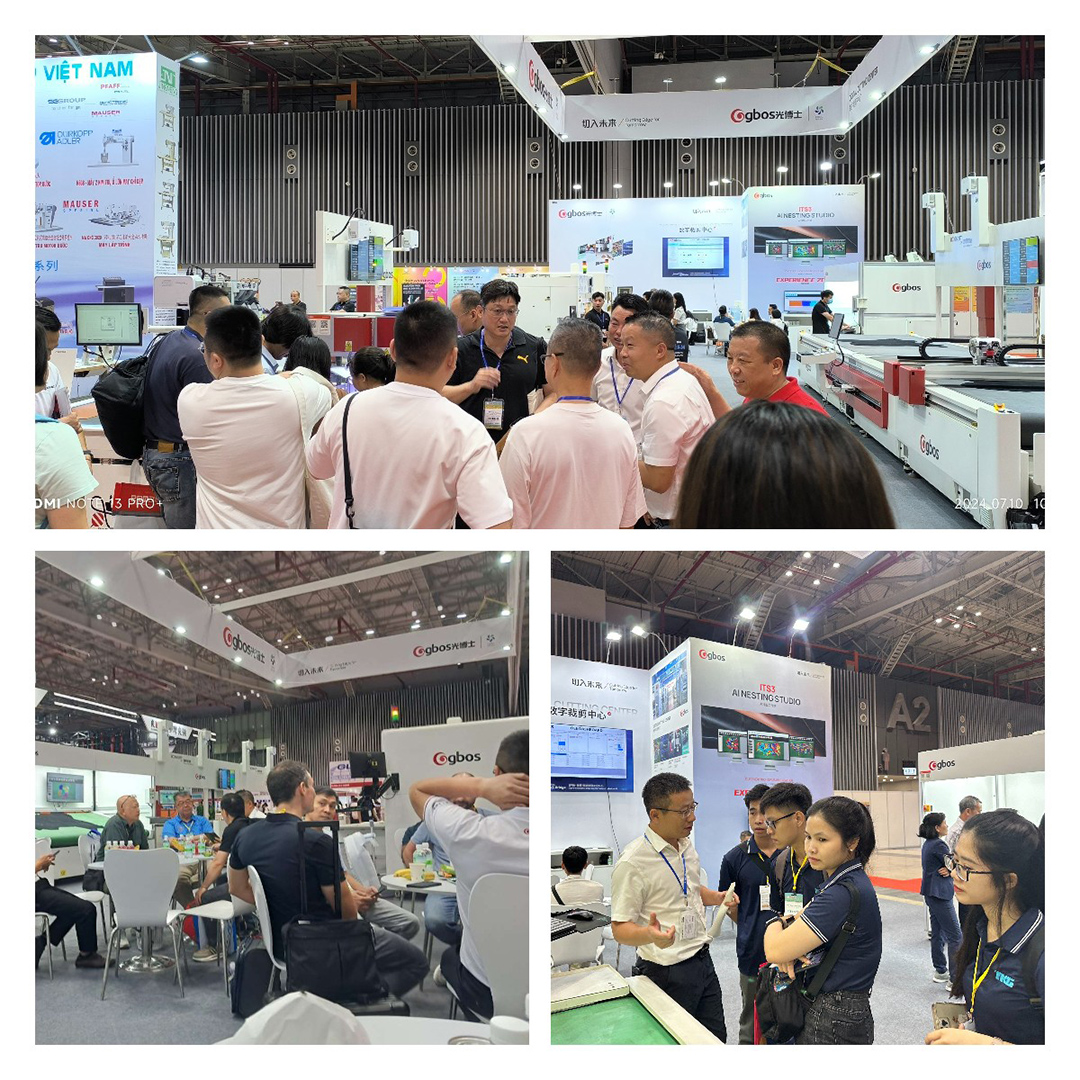

From July 10-12, during the three-day tech extravaganza, the Vietnam International Footwear, Leather & Industrial Equipment Exhibition concluded successfully at the Saigon Exhibition and Convention Center. This success was made possible by the joint efforts of the GBOS Vietnam local team and the headquarters team. The event not only brought together elite forces from the global footwear and leather industry but also showcased how GBOS, a leader in flexible intelligent equipment, drives industry transformation through technological innovation.

01

Hub of Technological Innovation

GBOS Stuns the Audience, Fostering In-depth Discussions with International Brands

GBOS, a globally recognized intelligent equipment brand, made a spectacular appearance with its cutting-edge exhibits, occupying a prime position at the exhibition. Its digital one-stop intelligent cutting and innovative process solutions, known for their exceptional efficiency, stability, and precision, garnered the attention of renowned brands like Wanbang, Asics, and Taekwang. Numerous visitors engaged in in-depth and professional discussions around every detail of GBOS’s machines, creating an extraordinarily lively atmosphere at the booth.

02

Empowering Smart Manufacturing with IoT

IoT Bridge Pioneers Digital Production Management

Notably, GBOS’s independently developed IoT Bridge technology became a focal point for many brands at the exhibition. By enabling unified management of manufacturing workshops, this technology effectively breaks down data silos, providing strong support for the digital management of production processes. This innovation not only enhances production efficiency but also lays a solid foundation for the intelligent transformation of enterprises.

03

Upgraded Solutions, Leading the Future

GBOS Showcases Latest Technological Achievements

At this event, GBOS presented a series of advanced solutions that have undergone comprehensive upgrades and optimizations. These solutions cover applications such as rule material nesting and cutting, leather-saving nesting and cutting, multi-layer material cutting (TPU, PU, etc.), high-speed shoe material line drawing, same-color engineering mesh AI recognition cutting, punching and cutting of hanging nail holes, and integrated fur material cutting with ITS3 cardboard matching functionality. Each technological innovation highlights GBOS’s exceptional ability to save materials, improve efficiency, ensure precision, and promote intelligent production, providing users with more diversified and customized production solutions.

04

Looking Ahead, Creating Brilliance Together

GBOS Looks Forward to Reuniting with You

GBOS sincerely thanks all partners and friends who supported and encouraged us at the Vietnam International Footwear and Leather Exhibition. Your trust and expectations are the driving force behind our continuous progress. Looking to the future, GBOS will continue to uphold the spirit of innovation, committed to advancing the intelligent development of the industry. We eagerly anticipate reuniting with you at the 2025 Vietnam Footwear and Leather Exhibition to witness the new leaps in GBOS technology and to jointly create a more brilliant future!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: