A New Chapter in Textiles Begins as We Embark on a Bright Future Together. The 2024 China International Textile Machinery Exhibition & ITMA Asia officially kicked off on October 14 at the National Exhibition and Convention Center (Shanghai). Spanning a massive 160,000 square meters, the event brings together nearly 1,700 textile machinery companies from countries including China, Germany, Japan, and Italy.

GBOS, a dedicated innovator in the field of intelligent equipment, showcased its latest products and solutions, drawing widespread attention from within and beyond the industry, thanks to its 19 years of R&D expertise.

01 Full Smart Innovation Technology

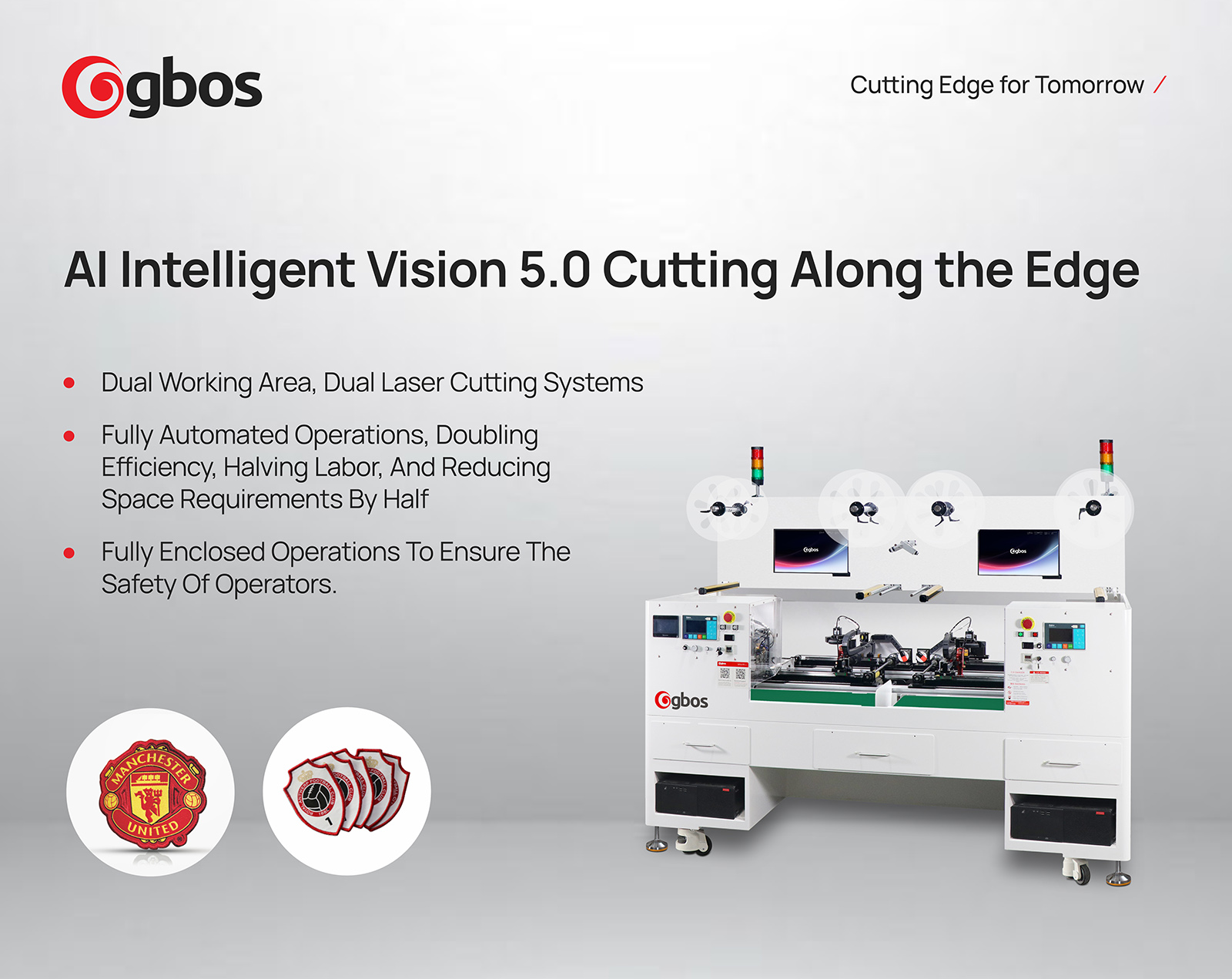

GBOS has always adhered to a customer-centric approach, continuously creating higher value for clients. At this exhibition, GBOS unveiled its latest innovation—the FB06CCD AI Smart Vision 5.0 Edge Cutting Machine. This breakthrough showcased GBOS’s accumulated technological advancements in the garment label (tag) sector, developed in collaboration with its users over the years.

The new CCD series cutting machine represents a complete upgrade, featuring an integrated design that combines multiple functions such as feeding, cutting, waste collection, robotic arm automatic material retrieval, and inspection table into one system. This not only optimizes the production process and improves efficiency but also ensures ease of operation and continuous production. Attendees expressed great interest in how this system simplifies operations while boosting productivity.

The high level of automation in the FB06CCD minimizes manual intervention throughout the production process, from material feeding to finished products, significantly reducing labor costs and enhancing product quality consistency. This revolutionary production model ensures high reliability in large-scale production of roll-type woven and embroidered labels, sparking lively discussions among attendees about the future of factory automation and intelligence.

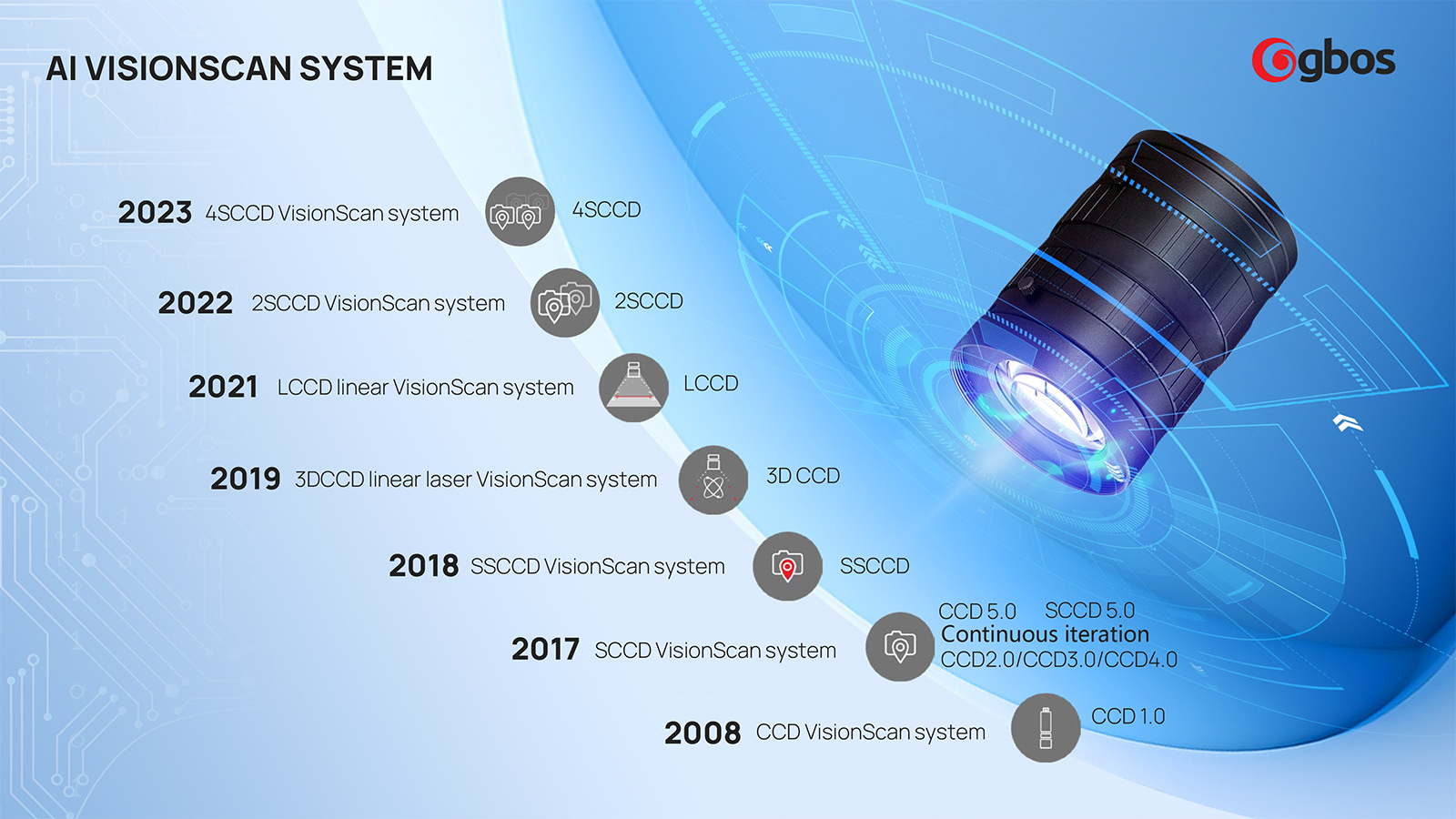

Another standout feature of the FB06CCD is its AI-powered visual recognition system. Supported by 16 years of visual recognition technology, it can identify complex patterns and similar-colored products in label designs, achieving precise cutting of label edges and key points. This AI-driven high recognition capability ensures perfect alignment of label patterns and flawless cutting of intricate designs, greatly improving cutting precision and enhancing the aesthetic appeal of labels.

The debut of the FB06CCD not only boosts production efficiency and product quality but also supports personalized and customized production with its flexibility and automation, driving the label cutting industry towards a more efficient, intelligent, and eco-friendly future.

02 Stunning Booth Display, Continuous Orders

While the FB06CCD stole the spotlight at the event, other GBOS equipment also garnered attention from attendees. Each machine, with its unique technological innovations and practical applications, sparked keen interest among industry professionals.

As the exhibition progressed, the GBOS team, filled with enthusiasm and expertise, warmly welcomed customers from all over the world. They patiently addressed queries and provided tailored solutions, making the booth a bustling hub of activity and securing numerous orders. The positive feedback from users and the significant number of signed orders are a testament to the excellence of GBOS products, as well as its technological innovation, service quality, and global strategic vision.

In the face of rapid changes in global manufacturing, GBOS will continue to collaborate with its partners to meet the challenges and seize the opportunities brought by digital transformation. Through ongoing technological innovation and service optimization, GBOS will help clients enhance their competitiveness and achieve sustainable development. Looking ahead, GBOS is committed to forging a brighter future for the textile industry with even greater determination and strides forward!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: