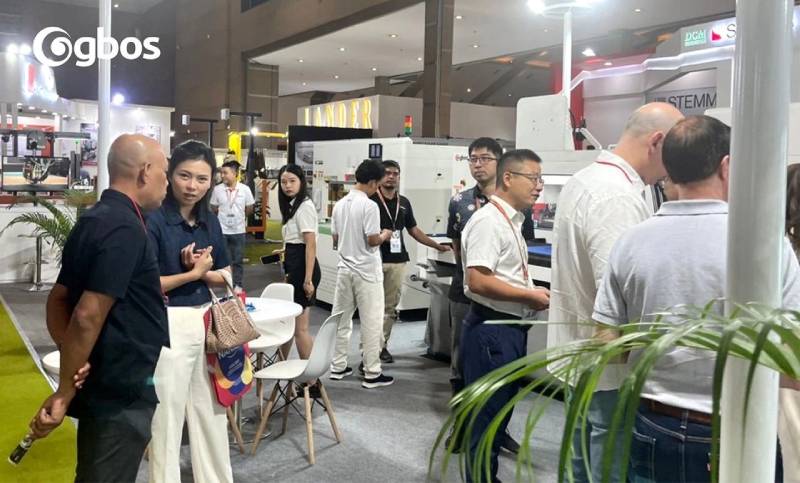

From August 14 to 16, 2025, the Jakarta Convention Center hosted the Indonesia International Leather and Footwear Exhibition (iLF 2025), a cornerstone event for Southeast Asia’s leather, footwear materials, machinery, and finished goods industries. The exhibition attracted a multitude of leading companies and veteran industry professionals, all keen to delve into the prolific business opportunities and expansive development potential offered by the Indonesian market.

A Strategic Hub in the Reshaping of the Global Industrial Chain

In recent years, Indonesia’s manufacturing industry has been advancing toward higher quality and greater efficiency, steadily moving into the ranks of major global manufacturing nations.

At present, the global manufacturing industry is undergoing profound transformation, with industrial and supply chains accelerating toward decentralization, diversification, and localization.

With abundant natural resources, a rapidly growing economy, a vast domestic market, a sufficient labor force, a favorable geographic location, strong government support for manufacturing, an improving business environment, and increasing foreign investment, Indonesia is emerging as one of the most important choices for global manufacturing enterprises seeking to diversify their production bases.

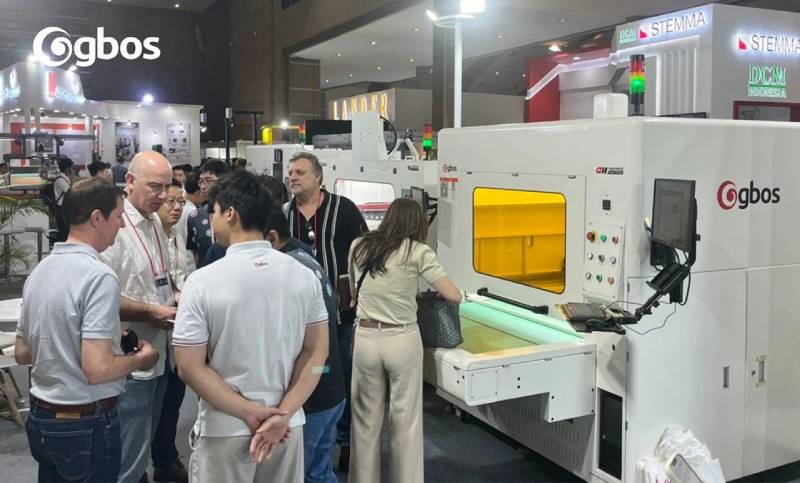

Leading with Cutting-Edge Technology, Empowering Industrial Transformation

The one-stop intelligent cutting and innovative process solutions developed by GBOS serve as a precise and powerful “production engine,” covering multiple software and product lines, including the ITS3 AI Intelligent Nesting System, Digital Knife System, Laser System, Non-standard/Automation solutions, and IoT Bridge.

These systems and products work in synergy and integrate seamlessly, building an efficiently operating intelligent manufacturing ecosystem.

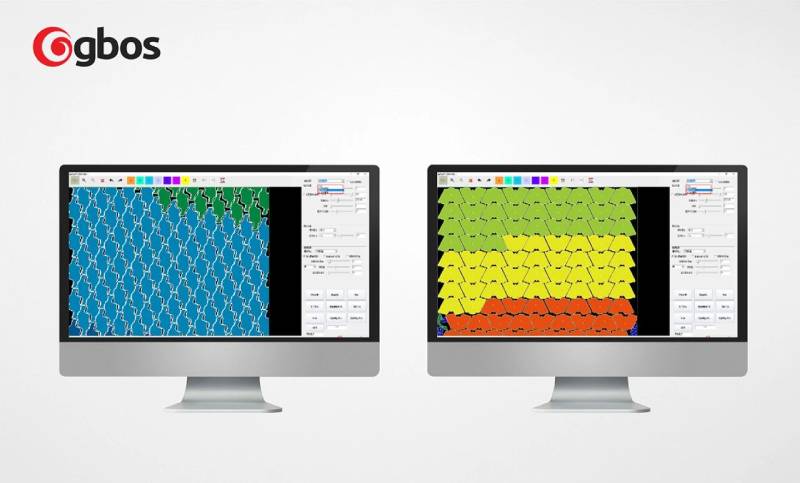

Notably, the latest GBOS AI large model has been deeply integrated into this solution. In leather application scenarios, it demonstrates outstanding performance and convenience—enabling precise recognition of different leather colors, regardless of their diversity, with accurate differentiation. It also precisely detects various defect marking colors without the need for secondary manual correction or parameter adjustment.

This feature greatly enhances the automation of the production process, minimizes human intervention, and ensures stable and highly efficient manufacturing.

GBOS’s AI VisionScan system can be regarded as a “superbrain,” offering high-precision, wide-range recognition capabilities. It handles applications such as same-color mesh cutting, tack hole punching, and midsole line marking with ease and efficiency.

The application of this system not only significantly shortens production cycles, enabling faster time-to-market and better meeting customer demands, but also substantially reduces labor costs and minimizes errors and material waste caused by manual operations, making efficient production truly attainable.

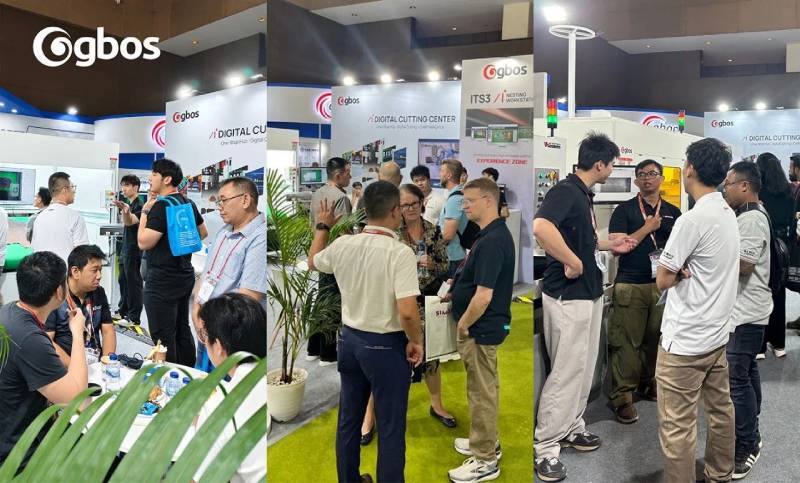

Experience Innovation: Redefining Traditional Nesting

GBOS has specially set up a materials nesting experience zone, allowing visitors to personally experience the advantages of digital nesting. Compared with traditional nesting, digital nesting leverages intelligent algorithms to precisely plan material usage, significantly improving efficiency and reducing waste.

This innovative experience completely changes the perception of traditional nesting, opening a new chapter of more efficient and intelligent production for leather and footwear manufacturers.

Localized Services, Deepening Presence in the Indonesian Market

As a leading intelligent manufacturing equipment company with 20 years of dedicated experience in flexible manufacturing, GBOS leverages its strong technological foundation and extensive industry expertise to actively expand its overseas presence.

Currently, GBOS has established 4S and 3S branches in Jakarta and Cilegon, Indonesia, respectively, creating a comprehensive localized service system covering pre-sales consultation, sales support, after-sales service, and spare parts supply. This efficient and attentive service is designed to deliver greater value to local customers.

Whether it’s equipment installation and commissioning, operator training, or later maintenance and troubleshooting, GBOS’s local team is ready to resolve issues promptly, greatly enhancing customer experience and production efficiency.

With the successful conclusion of the exhibition, GBOS not only showcased its cutting-edge technologies and innovative solutions in intelligent manufacturing to the Indonesian market, but also demonstrated its strong commitment to the market and ambitious vision for future development.

In the future, GBOS will continue to increase its investment in the Indonesian market, further optimize localized services, and collaborate with local enterprises to advance the leather and footwear manufacturing industry toward smarter and more efficient operations, contributing to the transformation and upgrading of Indonesia’s manufacturing sector.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: