From August 13–15, 2025, the 20th Shanghai International Automotive Interiors & Exteriors Exhibition (CIAIE 2025) — widely recognized as the trendsetter of the automotive interiors and exteriors industry — opened grandly at the Shanghai New International Expo Centre.

This global event brought together industry leaders and innovators from around the world, showcasing the latest breakthroughs in automotive interior and exterior technologies. More than just an exhibition, CIAIE 2025 has become a vital platform for technological innovation, industry collaboration, and supply chain integration, driving the next era of smart, sustainable, and high-quality automotive manufacturing.

From advanced materials to intelligent manufacturing equipment, and from innovative design concepts to eco-friendly solutions, the exhibition comprehensively showcased the latest achievements in the industry’s transformation toward digitalization, intelligent manufacturing, and sustainability.

GBOS in the Spotlight at CIAIE 2025

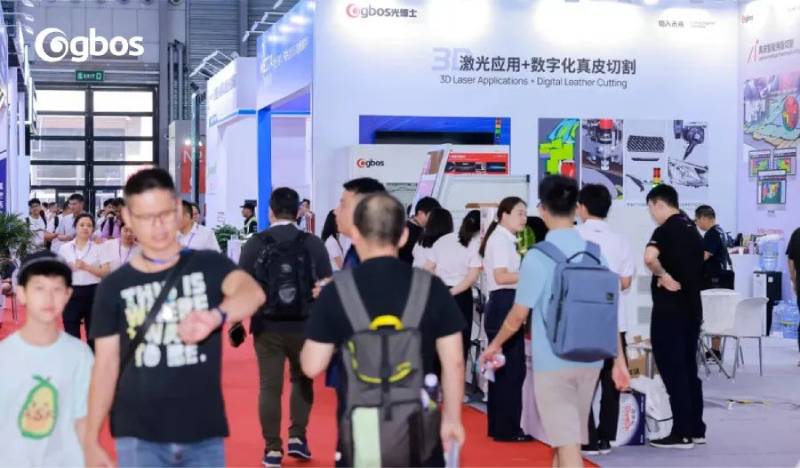

As a pioneer in the digital transformation of the automotive interiors and exteriors industry, GBOS made a high-profile appearance at the exhibition with its end-to-end intelligent solutions, becoming one of the main highlights of the event.

With the core theme of “Digital Empowerment · Smart Manufacturing for the Future”, the GBOS booth featured two major sections — a product experience zone and an industry exchange zone — attracting leading automakers, technology experts, and supply chain partners to engage in in-depth discussions and collaboration.

With professional insights and enthusiastic engagement, the on-site GBOS team provided every visitor with detailed explanations of the product features and technical advantages. The vibrant atmosphere of communication fully reflected GBOS’s strong influence and reputation within the automotive interiors and exteriors industry.

Diverse Applications Driving Industry Pain-Point Solutions

As the automotive industry accelerates its shift toward intelligent and personalized development, the production of automotive interiors and exteriors is facing multiple challenges — including higher precision requirements, optimized material utilization, and improved production efficiency.

At CIAIE 2025, GBOS presented its one-stop intelligent cutting solutions and innovative process system, centered on the integration of 3D laser applications and digital leather cutting technologies. This fusion builds a comprehensive smart manufacturing ecosystem for the entire scope of automotive interiors and exteriors, delivering precise solutions to the industry’s most pressing challenges.

In the field of automotive seat material cutting, GBOS equipment, with its outstanding precision multi-layer cutting capabilities, has opened up a new path for the efficient processing of PU composite mesh and foam materials, significantly shortening the material processing cycle.

In the field of intelligent leather cutting, the latest GBOS system powered by the AI large model enables integrated operations of material-saving nesting, line marking, and smart cutting — eliminating the need for manual repositioning. This innovation not only enhances operational efficiency and material utilization, but also provides strong support in reducing production costs for enterprises.

In the production of new energy vehicle through-lighting, the GBOS 3D laser engraving machine demonstrates exceptional process adaptability. Whether for paint engraving or plated surface treatment, it easily achieves a variety of precise, customized effects, meeting the demands of personalized automotive design.

The 3D five-axis cutting machine (GN702-3D) provides an ideal solution for the cutting and trimming challenges of various automotive injection-molded parts and complex-shaped products. Its open design allows seamless integration with automakers’ robotic arms, significantly enhancing the automation and efficiency of production lines.

Seizing Momentum for a New Journey, Leading the Industry Ahead

Looking at the industry’s development potential, as consumers’ demands for automotive quality and personalization continue to rise, the automotive interiors and exteriors sector is set to embrace even greater growth opportunities.

On one hand, digital and intelligent manufacturing will become the industry mainstream, helping companies improve production efficiency, reduce costs, enhance product quality, and meet personalized customization demands. On the other hand, the concepts of environmental protection and sustainability will drive continuous innovation in material selection and production processes.

GBOS’s series of innovative technologies and solutions align perfectly with the industry’s development trends, providing strong support for the transformation and upgrading of the automotive interiors and exteriors sector.

Amid the ongoing wave of innovation in the automotive industry, GBOS will continue to increase R&D investment and introduce innovative products and solutions, helping the automotive interiors and exteriors sector continuously overcome challenges and expand its development potential, ultimately delivering higher-quality and more personalized automotive experiences to consumers.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: