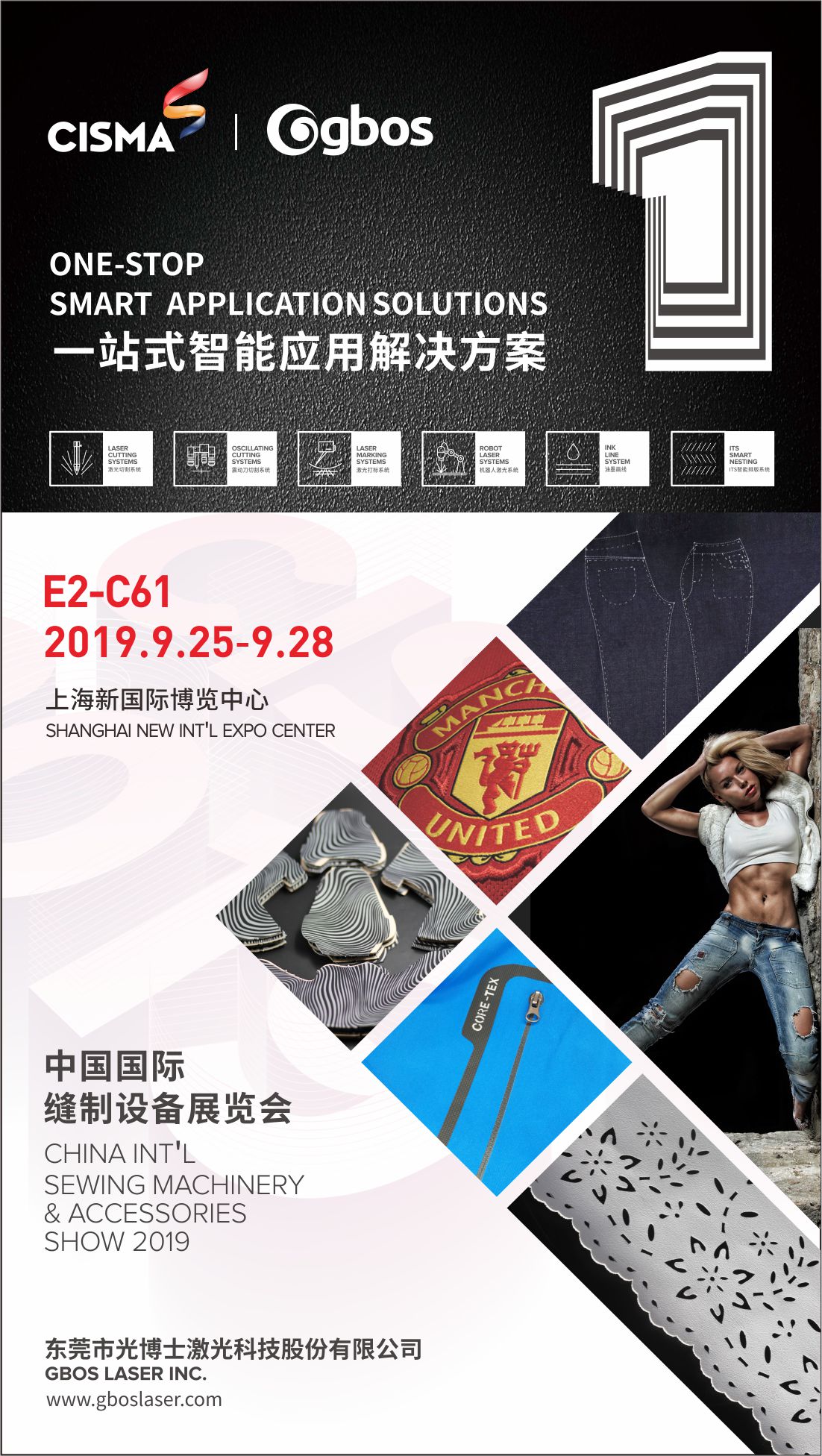

China International Sewing Machinery & Accessories Show (CISMA 2019) is very largest professional sewing machinery show in the world which will be held from Sept.25-28, 2019,at Shanghai New Int’l Expo Center. The theme of CISMA 2019 is “Smart Sewing Factory – Technologies and Solutions”. Sewing machinery industry is a typical equipment manufacturing industry and technological innovation is the original driving force for the development of the industry.

Booth information:

Exhibition: China International Sewing Machinery & Accessories Show (CISMA 2019)

Booth number: E2-C61

Time: Sept.25-28, 2019

Area: 120㎡

Venue: Shanghai New International Expo Centre, Century Park, Pudong, China

GBOS LASER has always been focusing on smart laser cutting & marking solutions for Garment/Garment Accessories/Denim Wash industries.

One-stop solutions for Apparel industry will be show on CISMA which can helps you increase quality and productivity, and meanwhile reduce your labor cost.

Exhibition equipment

XXP3 laser marking system, Integrated for both cutting & engraving & perforating

✓Super fast perforating air hole for fabric (High efficient perforating, 300 holes per second)

✓Kiss-cut cutting for heat transfer label

✓Super fast fabric marking

XXP5-600-2D the fifth generation of smart denim washing system

✓Exhaust system

✓Automatic feeding system

✓Red light positioning system

✓Projector positioning system

✓Portable projector positioning system

✓Multi application, integrated system (cat whiskers, scrapping, destroy, grinding, full prints)

S series laser system for cutting seamless bonding & label.

✓Camera positioning cutting system

✓ Double working table, Cut off and feeding system

✓ Any angle cutting & One time cutting multi patterns.

✓ Automatically identifying the defective products.

SCCD digital cutting system

✓Super camera smart visual-reading system

✓ Auto-feeding system

✓ Nesting system, saving material & auto counting

✓ IOT system (machine remote connection & control by man)

Multi-layer Oscillating knife cutting machine

✓Automatic feeding, gripping feed system

✓Projector preview and position- Convenient, fast.

✓Smart nesting-Save materials, high speed

✓No need Die-cut blade

GBOS is proud to be your partner for INDUSTRY 4.0!

GBOS Looking forward to you.

CISMA 2019 – The professional show is coming soon, Gbos laser is ready

September 07, 2023

Return To List

Recommended news

-

As smart manufacturing becomes the core engine driving the global leather industry upgrade, South Asia—supported by its unique industrial advantages and strong market potential—has rapidly emerged as a key focus for the worldwide leather manufacturing landscape. Recently, the 2025 Bangladesh International Leather Technology Expo successfully concluded at the Bashundhara International Convention City in Dhaka. As an innovator in intelligent cutting and a driving force in the digital transformation of the industry, GBOS showcased its full-scenario intelligent cutting systems and breakthrough process innovations at the event. With the strong capabilities of Chinese smart manufacturing, GBOS connected with South Asia’s industrial resources and explored new global partnerships, injecting powerful momentum into the region’s leather industry upgrade. 01 Positioning Ourselves at the South Asia Hub: Advancing the Future of the Leather Industry Together As the central hub of the leather industry in South Asia, Bangladesh has become a strategic destination for global leather enterprises expanding their international presence. With its well-established supply chain, strong production capacity, and rapidly growing market demand, the country continues to strengthen its position as a key global manufacturing base. GBOS has always placed strong emphasis on expanding its global presence, positioning the South Asia market as a vital...Pub Date: Dec 10, 2025

-

From October 28 to 31, 2025, ITMA2025 Asia Exhibition opened grandly at the Singapore Expo Center. Renowned as a “garden of innovation” in global textile machinery, the exhibition integrates core industry trends such as environmental sustainability, intelligent technology, and automation, illuminating the path for the textile industry’s upgrade. 01 Heading to the Textile Gala in Lion City With two decades of experience in intelligent manufacturing equipment, GBOS made a strong presence at ITMA2025 under the theme of *“full industry chain display + innovative technology + AI-driven solutions.”* The company set up three functional exhibition areas: product demonstration, technical consultation, and cooperation negotiation, offering forward-looking solutions for multiple textile scenarios. From precision fabric cutting and pattern matching to digital printing visual recognition, compact green denim washing, lace cutting, and roll-and-piece label processing, GBOS showcased solutions covering key links in textile production. These innovations support the industry in transitioning toward a new era of green and intelligent manufacturing through advanced technology. 02 Tailored Global Cooperation The GBOS booth attracted a steady stream of visitors, drawing representatives from textile companies worldwide. The professional team provided detailed explanations on topics such as: ●How the AI visual recognition system improves cutting accuracy ●How the green...Pub Date: Oct 30, 2025

/XXXP3.2-180.png)

/XXP5-600-2D.png)

/FB02CCD-CISMA.png)

/GH1610TT-SCCD.png)

/VC9-1612T-P-SCCD.png)

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: