Stock Code: 870145

Green Pioneer XXP5-AW Series

CO2 Laser Denim Finishing System

The Preferred High Speed Model for Jeans and Mass Production

High dynamic range imaging.

Washing water digital technology 6.0.

Double-station interactive work platform.

Specifications

Model

Description

Industry application

Modules

Working area

Whole power

Laser power

System requirements

Power supply

Product dimensions

Weight

Custom

Product Function

-

“Cloud” Support, Sharing Idea with Whole WorldProvide massive design resources, solve design requirements of users, boost massive saving in design costs and time.

“Cloud” Support, Sharing Idea with Whole WorldProvide massive design resources, solve design requirements of users, boost massive saving in design costs and time. -

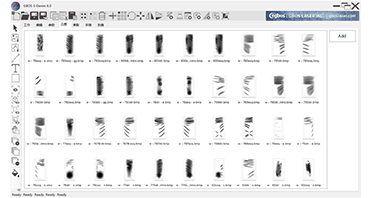

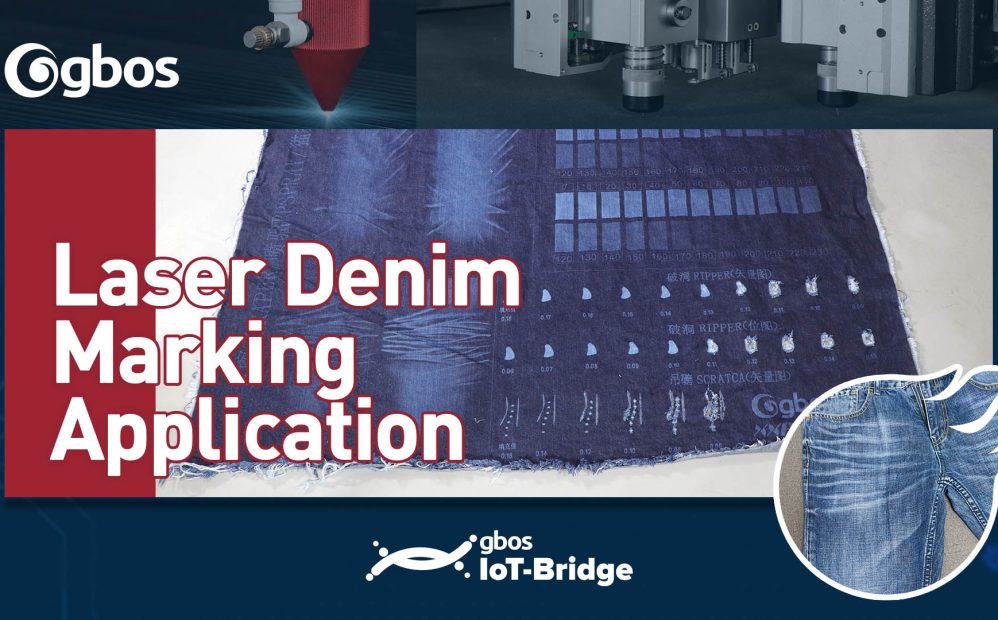

S-HDR, the Key Technology for Clear, Three-dimensional, Delicate and NaturalOver-motion range imaging laser technology, the images are clear, detailed and realistic. Also, makes the dark texture and shadow details perfectly presented.

S-HDR, the Key Technology for Clear, Three-dimensional, Delicate and NaturalOver-motion range imaging laser technology, the images are clear, detailed and realistic. Also, makes the dark texture and shadow details perfectly presented. -

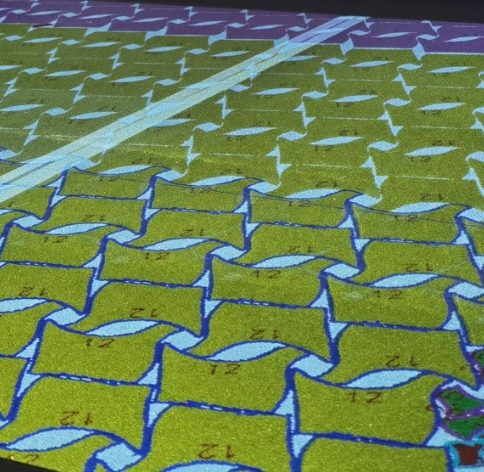

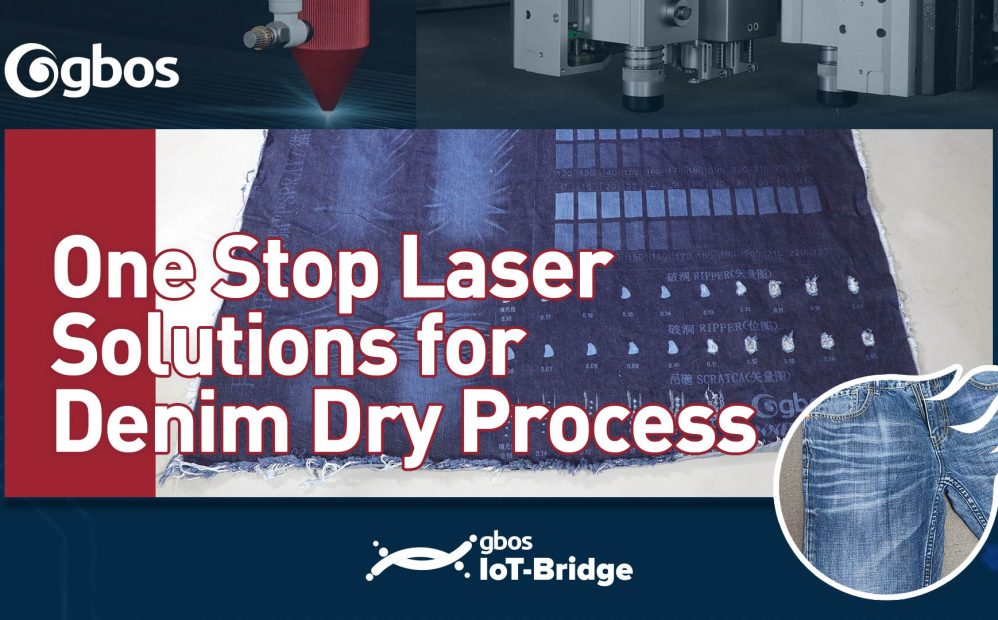

Pay Respect to Traditional Craftsmanship with Digital TechnologyIt has a natural sense like traditional crafts, with clear and delicate layering, different fashion styles can be created. (China, Japan & Korea Style: Minimalist, fresh and natural; Western style: Wild and bold.)

Pay Respect to Traditional Craftsmanship with Digital TechnologyIt has a natural sense like traditional crafts, with clear and delicate layering, different fashion styles can be created. (China, Japan & Korea Style: Minimalist, fresh and natural; Western style: Wild and bold.) -

Process 6.0, Increase Capacity and Efficiency while Achieving CustomizationDestroy effect 5 seconds/2 legs; Cat whisker, Monkey wash 25 seconds/2 legs; Grinding effect 2 seconds/2 legs; Full Printing 3 minutes/2 legs.

Process 6.0, Increase Capacity and Efficiency while Achieving CustomizationDestroy effect 5 seconds/2 legs; Cat whisker, Monkey wash 25 seconds/2 legs; Grinding effect 2 seconds/2 legs; Full Printing 3 minutes/2 legs. -

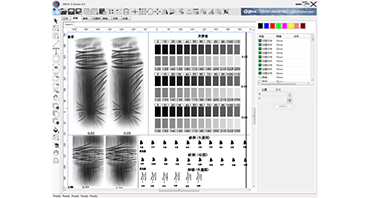

Precisely Control of Process EffectsControllable parameters of weft strength; Arbitrary adjustment of partial deformation; Accurate adjustment of partial gray scale and intensity.

Precisely Control of Process EffectsControllable parameters of weft strength; Arbitrary adjustment of partial deformation; Accurate adjustment of partial gray scale and intensity. -

Ecology 6.0, to Promote Carbon Neutrality and Sustainable Development Strategies for EnterpriseProcess without chemical, working environment is guaranteed; Compared to traditional manual: No CO2 emission, contribute to achieving carbon neutrality targets.

Ecology 6.0, to Promote Carbon Neutrality and Sustainable Development Strategies for EnterpriseProcess without chemical, working environment is guaranteed; Compared to traditional manual: No CO2 emission, contribute to achieving carbon neutrality targets. -

The Whole Process is EasyOne-Click solution for denim washing process, no skill requirement for operator, no proficiency requirement, operate like cover your eyes.

The Whole Process is EasyOne-Click solution for denim washing process, no skill requirement for operator, no proficiency requirement, operate like cover your eyes. -

Simulation Effect Preview and PositioningVisual simulation background and positioning; Projection simulation effect preview and positioning, convenient to identify, real-time presentation of process effects.

Simulation Effect Preview and PositioningVisual simulation background and positioning; Projection simulation effect preview and positioning, convenient to identify, real-time presentation of process effects. -

The Preferred Model for Jeans and Mass ProductionIntelligent interactive work, continuously working without waiting, front and back sides and multiple processes in one time! 30% faster than the 5th generation.

The Preferred Model for Jeans and Mass ProductionIntelligent interactive work, continuously working without waiting, front and back sides and multiple processes in one time! 30% faster than the 5th generation. -

Executive StandardWith 3 Emergency stop switches, have safety isolation protection between loading & unloading area and laser processing area, 2 feeding operation switches, IP54 electric dust-proof design.

Executive StandardWith 3 Emergency stop switches, have safety isolation protection between loading & unloading area and laser processing area, 2 feeding operation switches, IP54 electric dust-proof design.

Expand More +

Functions & Modules

-

Real-time preview of nesting result, convenient and fast. Real-time nesting, manual insert, maximize material utilization rate.More Details

Real-time preview of nesting result, convenient and fast. Real-time nesting, manual insert, maximize material utilization rate.More Details -

Purify and treat the smoke and waste gas generated during the cutting processMore Details

Purify and treat the smoke and waste gas generated during the cutting processMore Details

Expand More +

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: