Stock Code: 870145

XXP3S-320

Automatic Feeding CO2 Laser Marking System

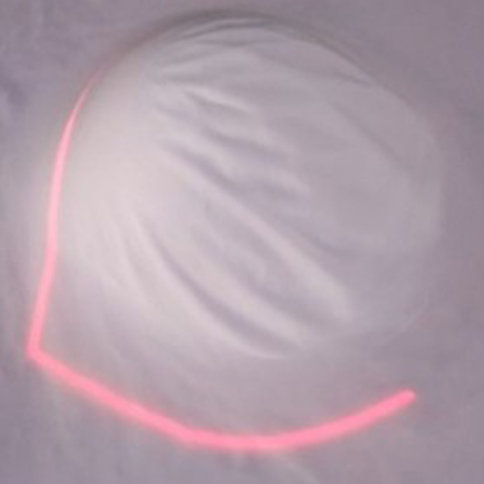

Faster speed. It is more suitable for thick materials, leather and other roll materials, especially suitable for batch perforation, engraving, and other laser marking applications of roll PU, PUV and other materials. The efficiency is more than 3 times higher than that of ordinary marking machines. The feeding and cutting machine has been improved by more than 10 times.

Especially suitable for rolling materials.

More than 10 times that of ordinary auto feeding cutting machine.

PUV and other materials need batched perforation,engraving, and marking applications.

The world's only one automatic feeding marking system customized for rolling materials.

Compared with the common marking machine,the efficiency increases more than 3 times.

| Working area | Gross power | Laser power | Power supply | Dimension | Overall weight | System compatible format |

|---|---|---|---|---|---|---|

| 1600*400mm | 12170W | 320W | 380V 50Hz/60Hz | 3107X1610X1900mm | 1200kg | Windows XP/7/8/10,Al,PLT,DXF.DST,BMPJPG,JPEG,PNG |

Functions & Modules

-

Purify and treat the smoke and waste gas generated during the cutting processMore Details

Purify and treat the smoke and waste gas generated during the cutting processMore Details -

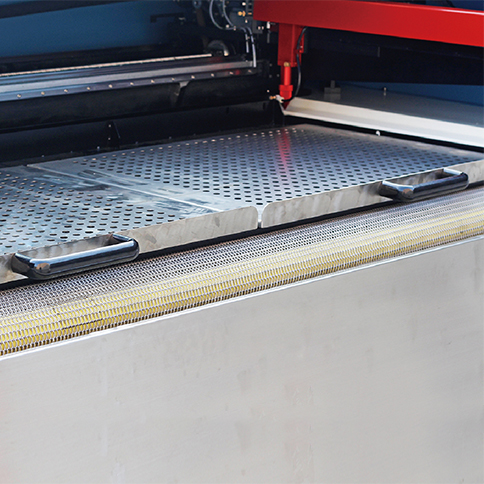

Different mesh panel materials and structures are suitable for different cutting materials and requirements.More Details

Different mesh panel materials and structures are suitable for different cutting materials and requirements.More Details

Expand More +

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: