Stock Code: 870145

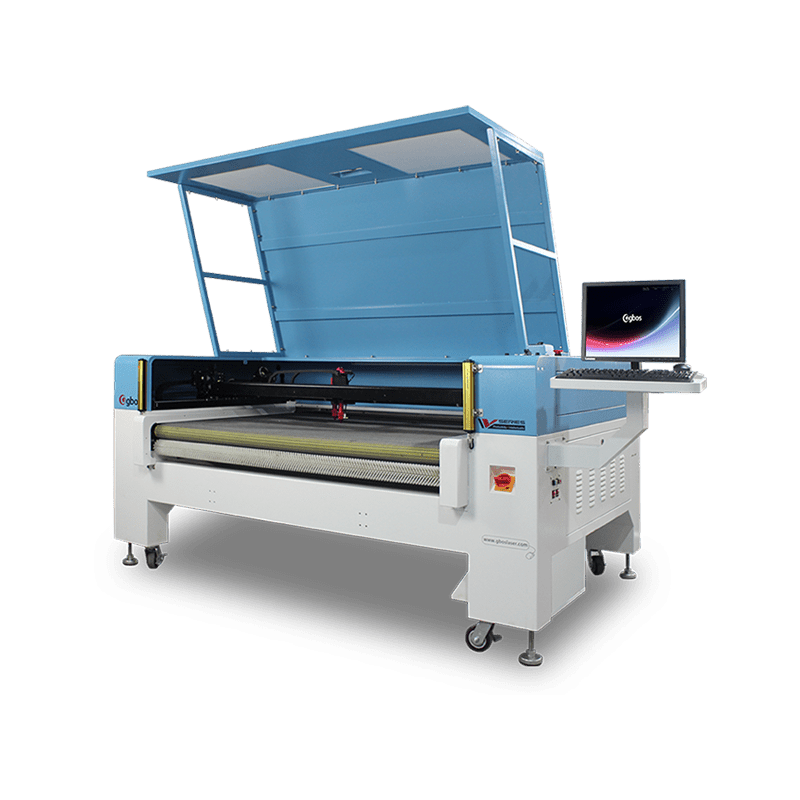

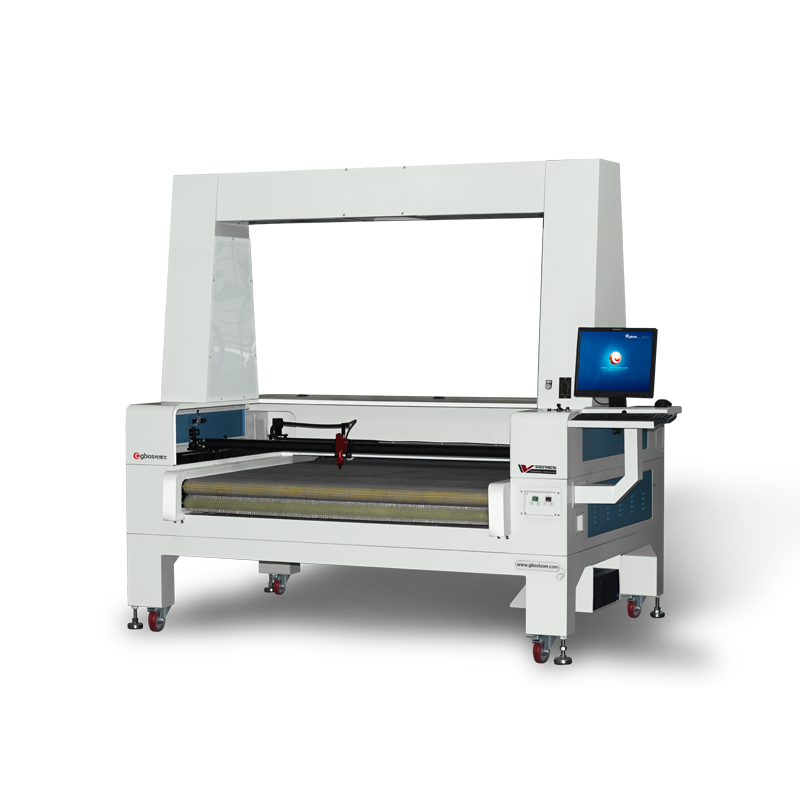

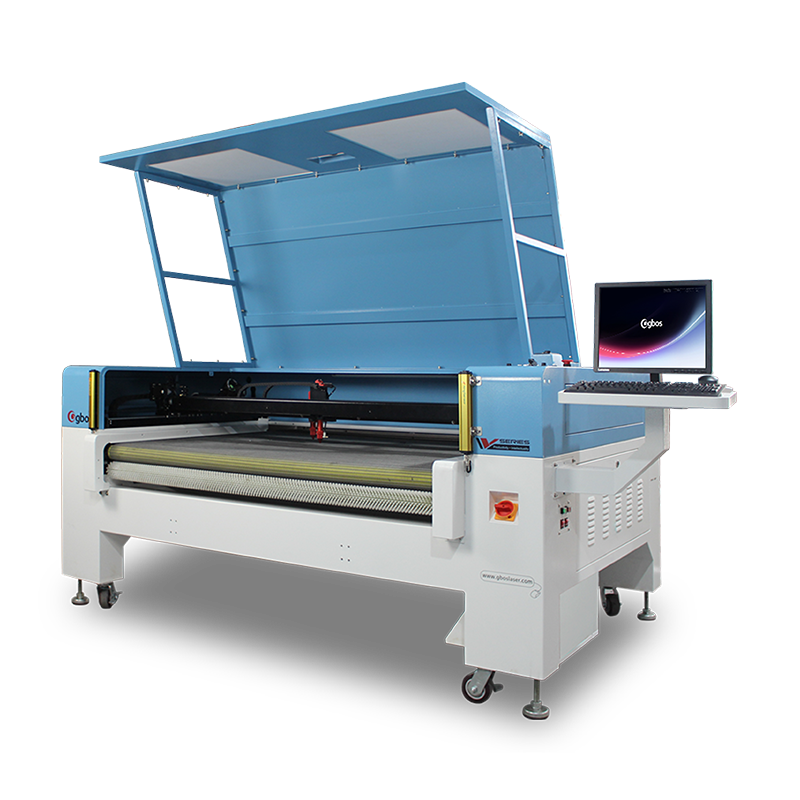

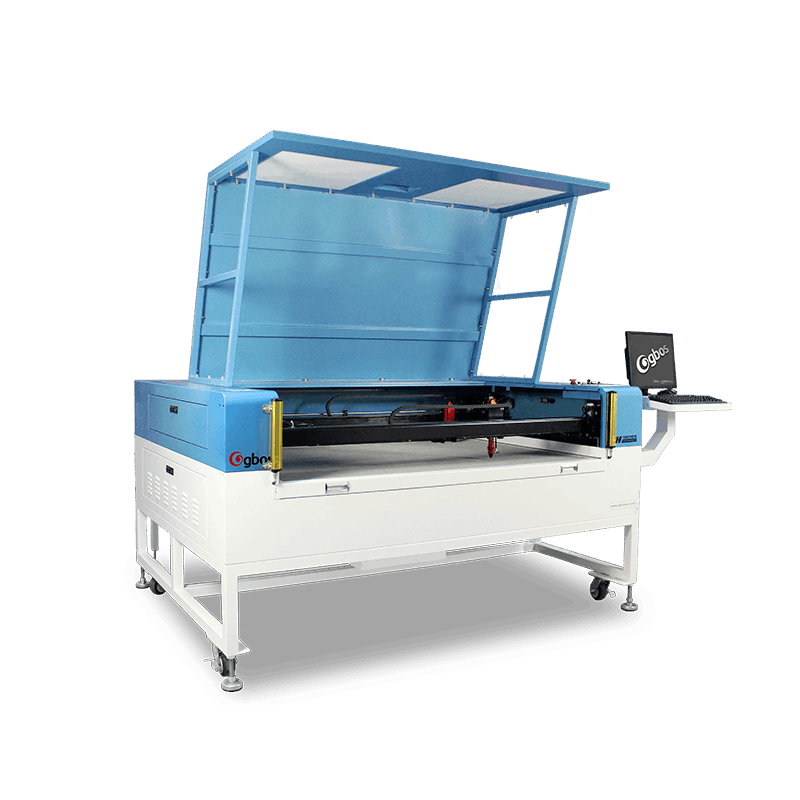

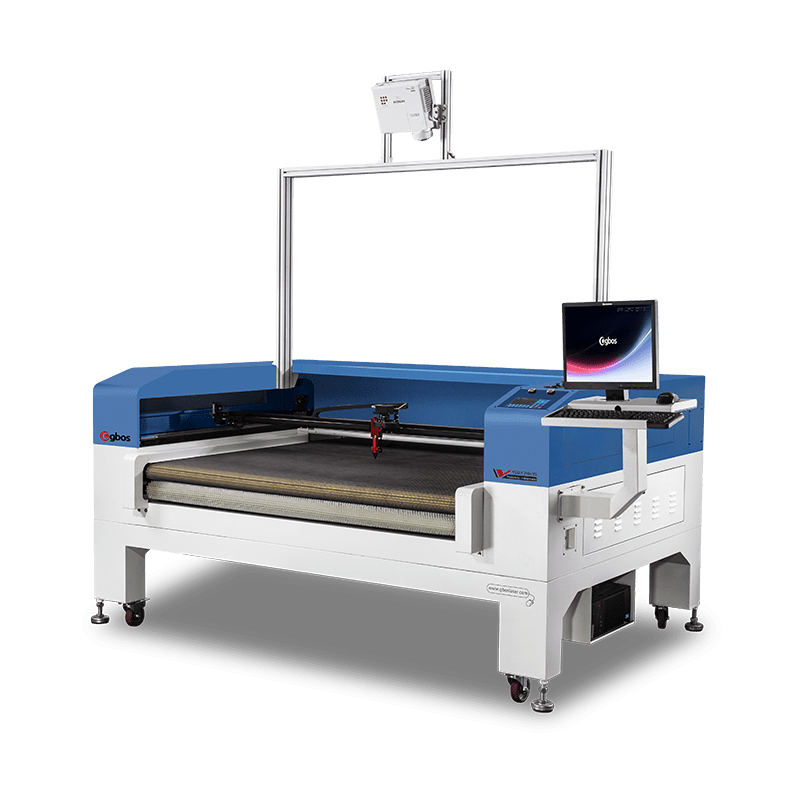

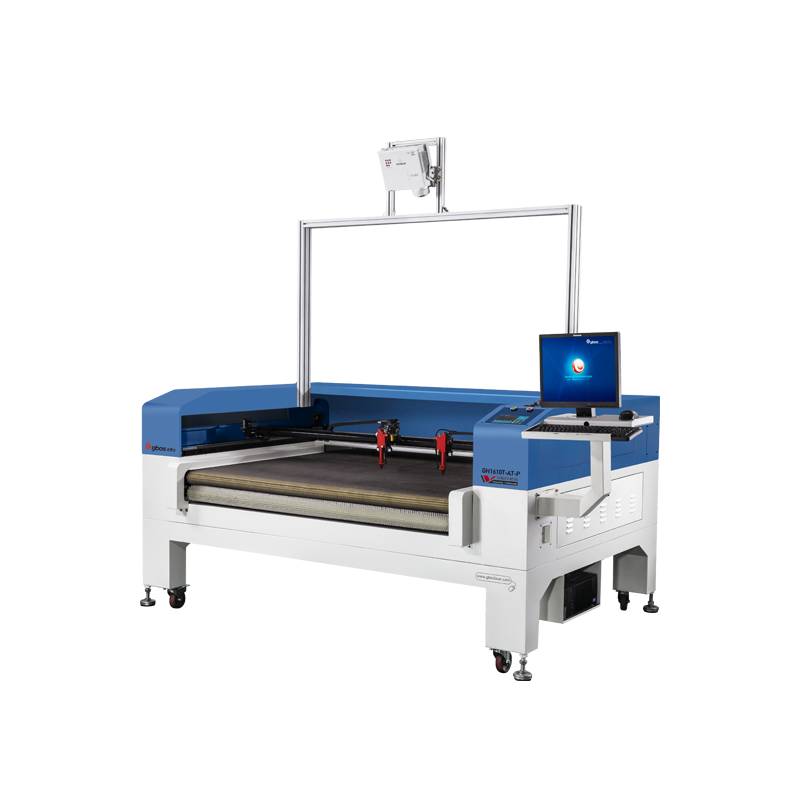

V7 Series

AI VisionSan laser cutting machine

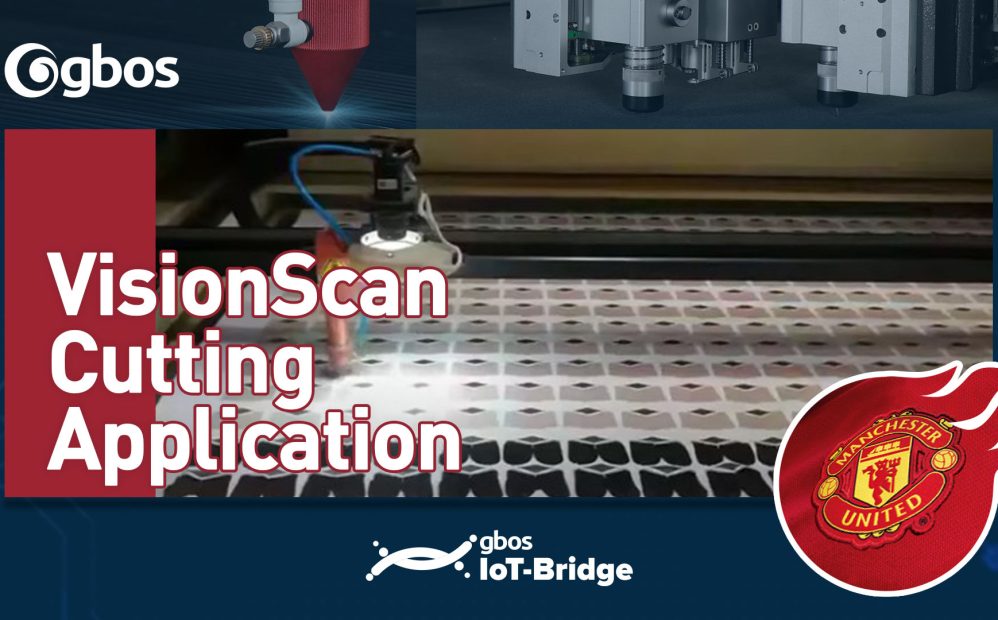

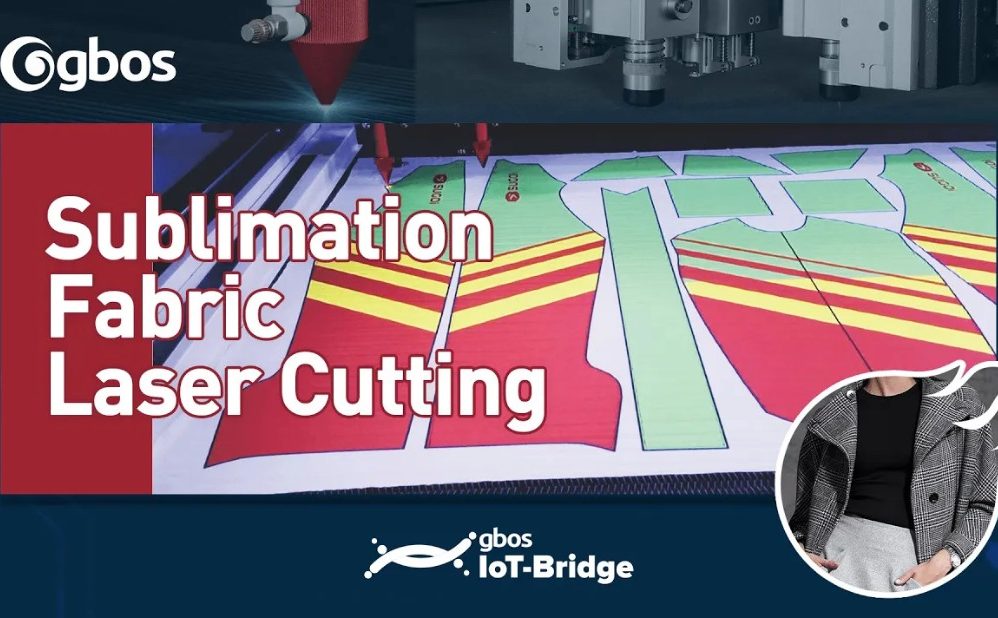

Equipped with SCCD AI VisionScan function, which automatically recognizes the contour of fabric patterns and edge shapes, ensuring precise cutting.

Smart zoom.

Border cutting.

No yellow, burnt edge.

Super camera positioning.

Automatic extraction of contour.

Automatic locking of knitted fabrics.

Specifications

Model

Description

Industry application

Modules

Working area

Whole power

Laser power

System requirements

Power supply

Product dimensions

Weight

Custom

Product Function

-

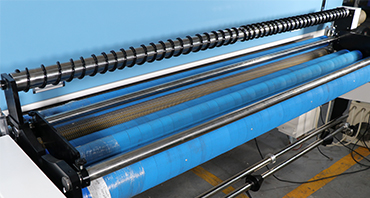

Integrated Design with Feeding System① Truly integrated feeding system, not pulling shelf. ② Multi-material auto-feeding: knitted fabric, cloth, leather, foam,(capable of multi-layers feeding).

Integrated Design with Feeding System① Truly integrated feeding system, not pulling shelf. ② Multi-material auto-feeding: knitted fabric, cloth, leather, foam,(capable of multi-layers feeding). -

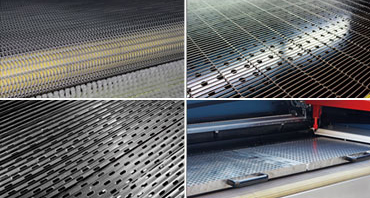

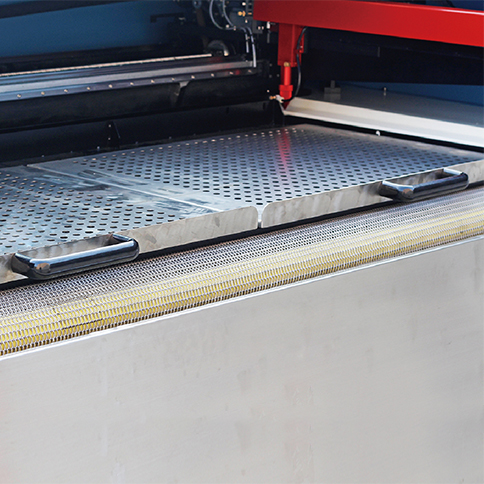

Multi Conveyor Bed for Option① Herringbone for soft fabric. ② Grid for leather. ③ E style for footwear industry. ④ 850T for more safety. Characteristic setting and cutting

Multi Conveyor Bed for Option① Herringbone for soft fabric. ② Grid for leather. ③ E style for footwear industry. ④ 850T for more safety. Characteristic setting and cutting -

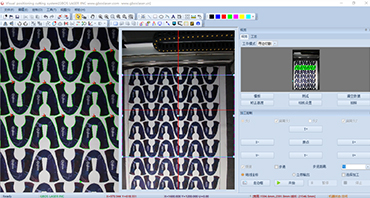

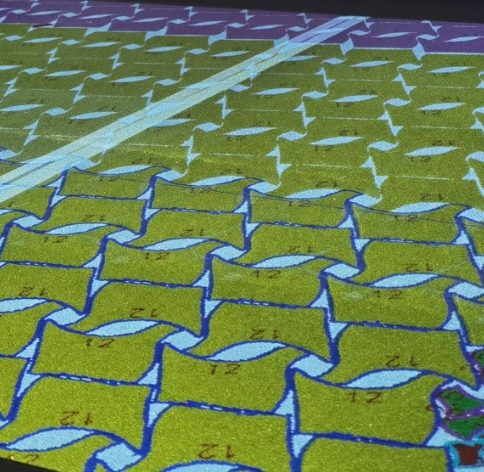

AI SCCD VisionScan Large Size Cutting for Digital Printing① System Automatic extraction of contours within 5 seconds (big size fabric pattern outline recognition, no need Graphic processing) ② System automatic extraction of contours and then border cutting edges immediately.

AI SCCD VisionScan Large Size Cutting for Digital Printing① System Automatic extraction of contours within 5 seconds (big size fabric pattern outline recognition, no need Graphic processing) ② System automatic extraction of contours and then border cutting edges immediately. -

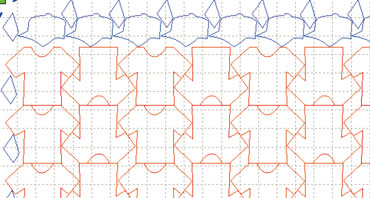

Automatic Size Grading① Input the pattern from software graphics library. ② The left side of software will arrange the sizes one by one. ③ Choose the file to process, drag it to the working area of the software.

Automatic Size Grading① Input the pattern from software graphics library. ② The left side of software will arrange the sizes one by one. ③ Choose the file to process, drag it to the working area of the software. -

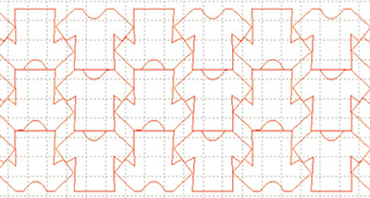

Smart Nesting-waste Saving and Fast (option)Odd number arranging/Waste saving arranging/Unlimited lenth nesting/ Auto calculating. Supper camera positioning function. Feature outline extraction. Software can directly scan and extract graphics contour. Multiple patterns cutting. Any design, any angle intelligent identifying cutting. Characteristic setting and cutting. Large pattern positioning, consistent cutting size. Automatically adjusted according to the printing contour. Including the deviation, deformation correction, rotation correction, alignment correction and multi-patterns cutting.

Smart Nesting-waste Saving and Fast (option)Odd number arranging/Waste saving arranging/Unlimited lenth nesting/ Auto calculating. Supper camera positioning function. Feature outline extraction. Software can directly scan and extract graphics contour. Multiple patterns cutting. Any design, any angle intelligent identifying cutting. Characteristic setting and cutting. Large pattern positioning, consistent cutting size. Automatically adjusted according to the printing contour. Including the deviation, deformation correction, rotation correction, alignment correction and multi-patterns cutting.

Expand More +

Functions & Modules

-

System Automatic extraction of contours within 5 seconds. (Large size pattern outline recognition), no need graphic processing, can instantly get the drawing file and then cut.More Details

System Automatic extraction of contours within 5 seconds. (Large size pattern outline recognition), no need graphic processing, can instantly get the drawing file and then cut.More Details -

Real-time preview of nesting result, convenient and fast. Real-time nesting, manual insert, maximize material utilization rate.More Details

Real-time preview of nesting result, convenient and fast. Real-time nesting, manual insert, maximize material utilization rate.More Details -

Continuously working, efficiency increased again. Materials auto feeding, easier to operate and more automated than traditional feeding.More Details

Continuously working, efficiency increased again. Materials auto feeding, easier to operate and more automated than traditional feeding.More Details -

Continuously working, efficiency increased again. Materials auto feeding, easier to operate and more automated than traditional feeding.More Details

Continuously working, efficiency increased again. Materials auto feeding, easier to operate and more automated than traditional feeding.More Details -

Achieve digital management, reduce paper-oriented work, empowering “Carbon Neutral” goals.More Details

Achieve digital management, reduce paper-oriented work, empowering “Carbon Neutral” goals.More Details -

Enabling asynchronous cutting of different shapes, improving production efficiency and reducing production time.More Details

Enabling asynchronous cutting of different shapes, improving production efficiency and reducing production time.More Details -

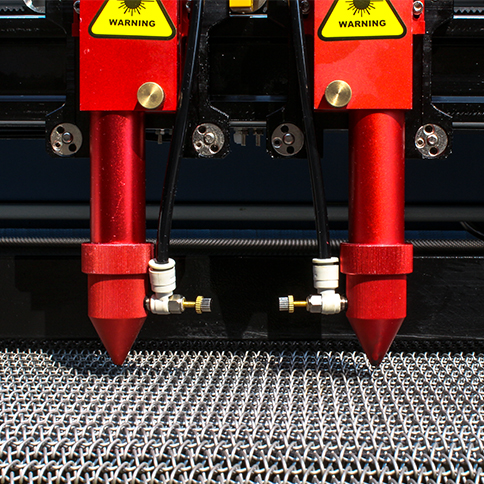

Dual laser head on a single track, greatly improve efficiency.More Details

Dual laser head on a single track, greatly improve efficiency.More Details -

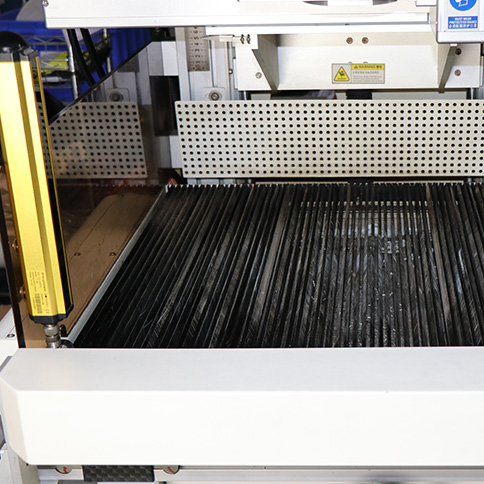

The advantages of using a blade mesh panel as the cutting table for CO2 laser marking machine are as follow:More Details

The advantages of using a blade mesh panel as the cutting table for CO2 laser marking machine are as follow:More Details -

It has many advantages when using a grid panel on CO2 laser cutting machine.More Details

It has many advantages when using a grid panel on CO2 laser cutting machine.More Details -

Different mesh panel materials and structures are suitable for different cutting materials and requirements.More Details

Different mesh panel materials and structures are suitable for different cutting materials and requirements.More Details

Expand More +

Industry Solutions

-

Garment Industry

-

Footwear Industry

-

Leather Goods

-

Craft & Gift Industry

-

Lingerie Industry

-

Automotive Interior Industry

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: