Stock Code: 870145

MS Series

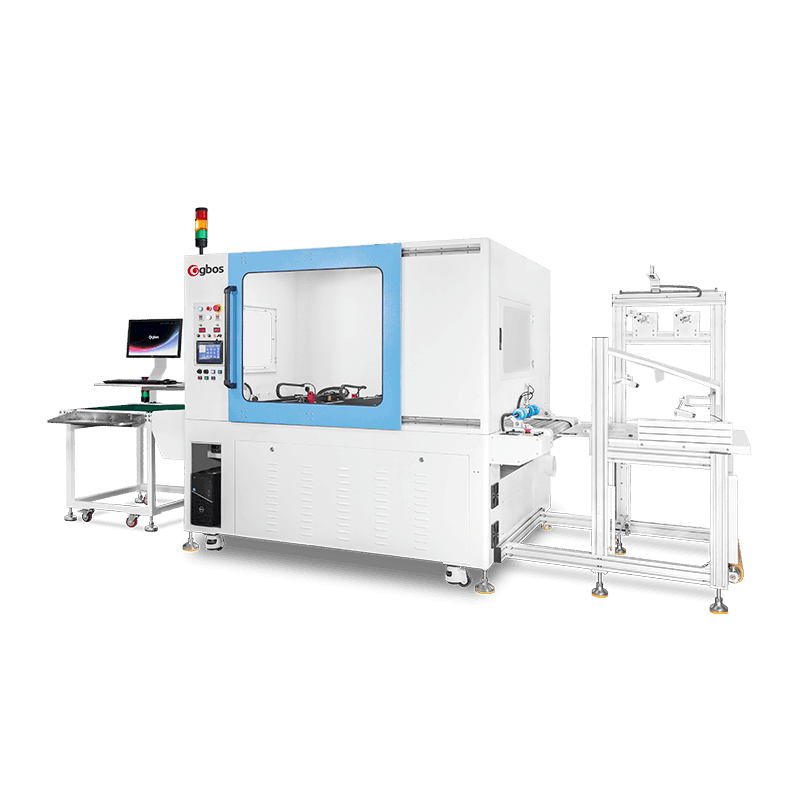

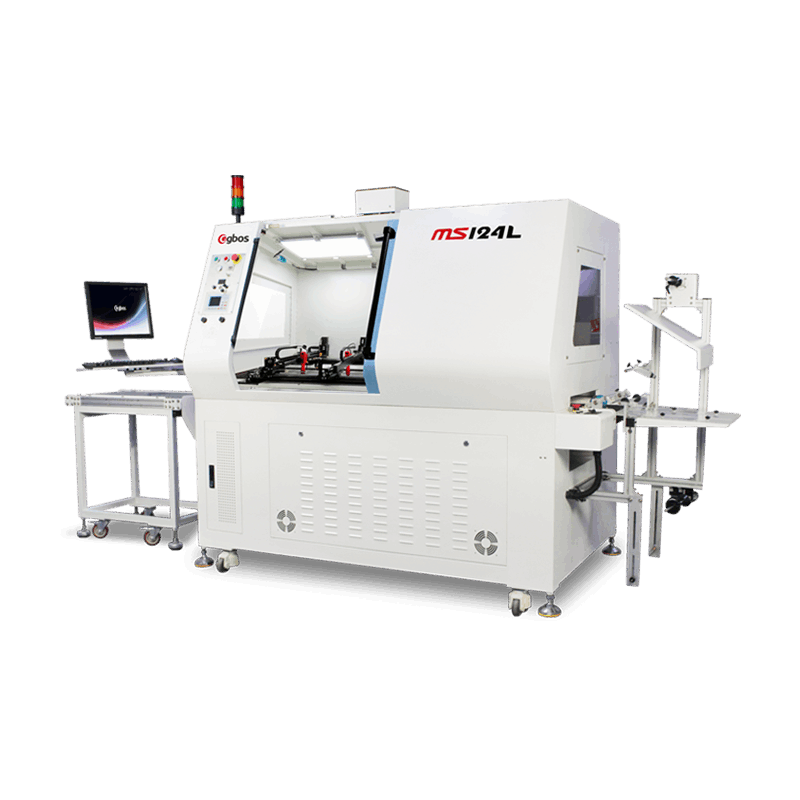

AI VisionScan & Positioning Lace Laser Cutting Machine

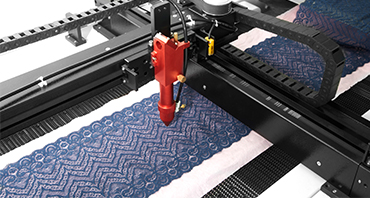

Specifically engineered for rolling lace automatic cutting, our Lace Laser Cutting Machine employs advanced camera technology for lace feature recognition, ensuring high-precision cutting of fixed points and scallops. This machine excels in cutting multiple patterns simultaneously and operates continuously, making it ideal for large-scale production. Additionally, it is user-friendly, requiring only one operator for efficient piece collection.

The Sino-European team jointly developed an intelligent laser lace cutting machine.

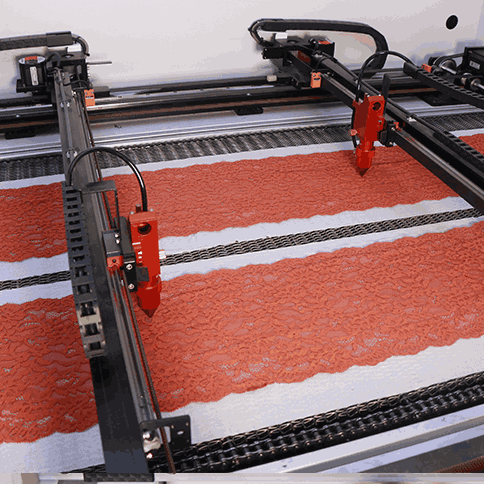

Big working size multi-position cutting, multi-design layout one time, save fabric, save time.

One time molding technology, process reduction, save labour, more accurate and more efficient.

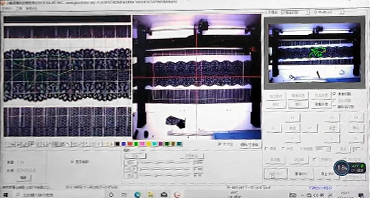

Equipped with automatic feeding and special visual reading system developed for the irregular and easy-to-stretch characteristics of lace to achieve precise positioning and cutting.

The whole machine adopts CE safety standard design and intelligent manufacturing, and the whole machine is more stable and safe.

Specifications

Model

Description

Industry application

Modules

Working area

Whole power

Laser power

System requirements

Power supply

Product dimensions

Weight

Custom

Product Function

-

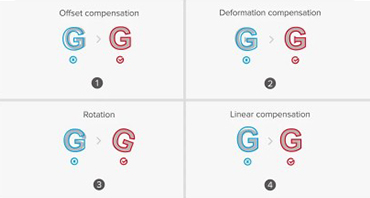

Precise and Intelligence CuttingPositioning accuracy of ±0.5mm, the best in the lace laser industry. Defective products can be selected.

-

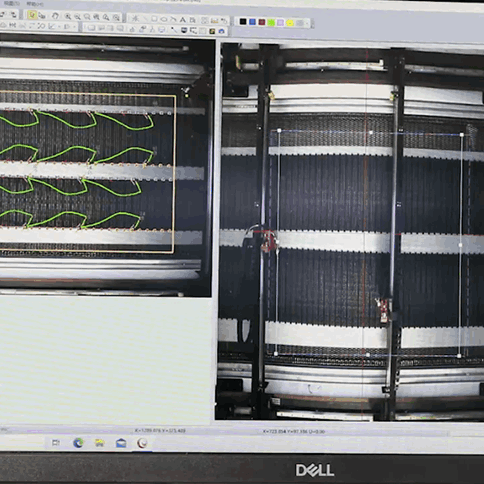

Positioning Cutting for Multiple DesignBig working size multi-position cutting, Multi-design layout one time, save fabric, save time; One time molding technology, Process reduction, save labour, more accurate and more efficient; No Missing, cutting precision ±0.5mm.

-

High Definition Industrial CameraBig working size multi-position cutting. Multi-design layout one time, save fabric, save time.

-

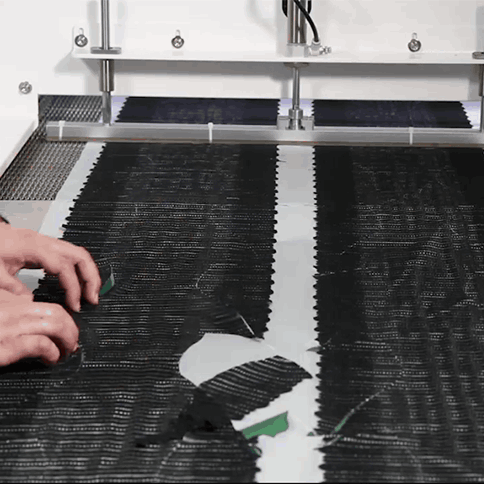

High Precision of Conveyor System for Soft Materials (Patent of China)Auto-feeding system:1200*400mm working size; and equipped with collect table.

-

Design with CE standards, Automation, Integration DesignWarning Lamp: Remind the laser machine running state, convenient for the engineer operation. One engineer can control more machine. Automatically and seal work.

Expand More +

Functions & Modules

-

Enabling asynchronous cutting of different shapes, improving production efficiency and reducing production time.More Details

-

Continuously working, efficiency increased again. Materials auto feeding, easier to operate and more automated than traditional feeding.More Details

Expand More +

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: