Stock Code: 870145

GB Series

GB Series Laser Marking Machine

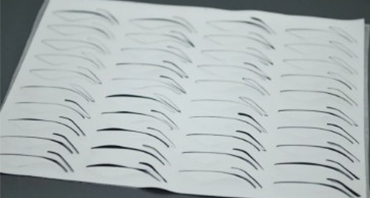

Equipped with a US-made metal CO2 laser and high-precision optical system, suitable for small-area high-precision engraving and cutting needs.

High-speed optical galvanometer system.

Meet precision processing requirements for industrial applications.

Optional X, Y-axis movable working table for large-format material processing.

Specifications

Model

Description

Industry application

Modules

Working area

Whole power

Laser power

System requirements

Power supply

Product dimensions

Weight

Custom

Product Function

-

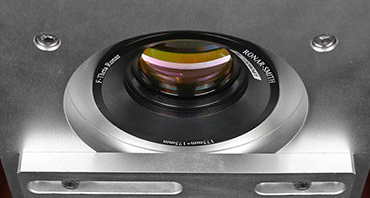

High Speed Vibrating LensPrecise layered cutting,stable performance, high speed.

High Speed Vibrating LensPrecise layered cutting,stable performance, high speed. -

American CO2 Coherent Laser GeneratorAdopt metal laser generator, high precision, create higher quality samples.

American CO2 Coherent Laser GeneratorAdopt metal laser generator, high precision, create higher quality samples. -

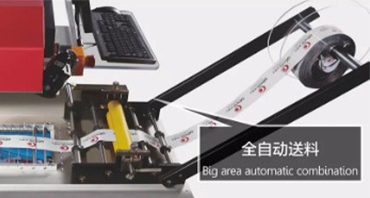

Auto Feeding(optional)Suitable for marking on cloth fabric, leather and non-metal materials roll package.

Auto Feeding(optional)Suitable for marking on cloth fabric, leather and non-metal materials roll package. -

XYP Device(optional)4 axis moving table, it can move side to side, continuous work; Auto line-up of large pattern.

XYP Device(optional)4 axis moving table, it can move side to side, continuous work; Auto line-up of large pattern. -

CCD Positioning(optional)VisionScan cutting; VisionScan engraving; VisionScan cutting + marking code; VisionScan cutting+engraving+marking code. VisionScan marking code(production date code);

CCD Positioning(optional)VisionScan cutting; VisionScan engraving; VisionScan cutting + marking code; VisionScan cutting+engraving+marking code. VisionScan marking code(production date code);

Expand More +

Functions & Modules

-

Realize intelligent identifying cutting along the edge, the identifying range: about 150mm*120mm.More Details

Realize intelligent identifying cutting along the edge, the identifying range: about 150mm*120mm.More Details

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: