Stock Code: 870145

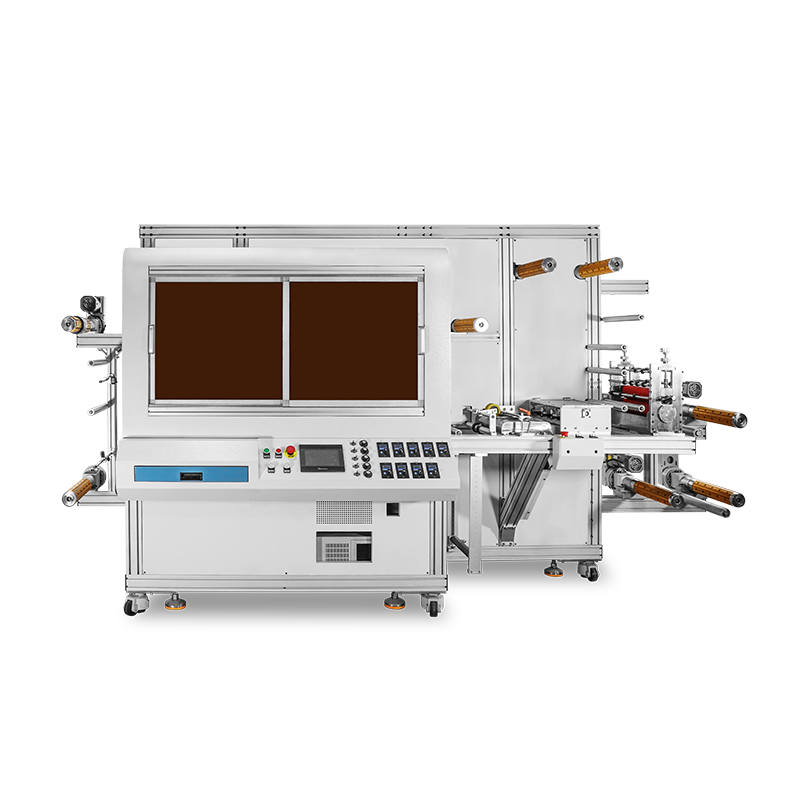

P Series

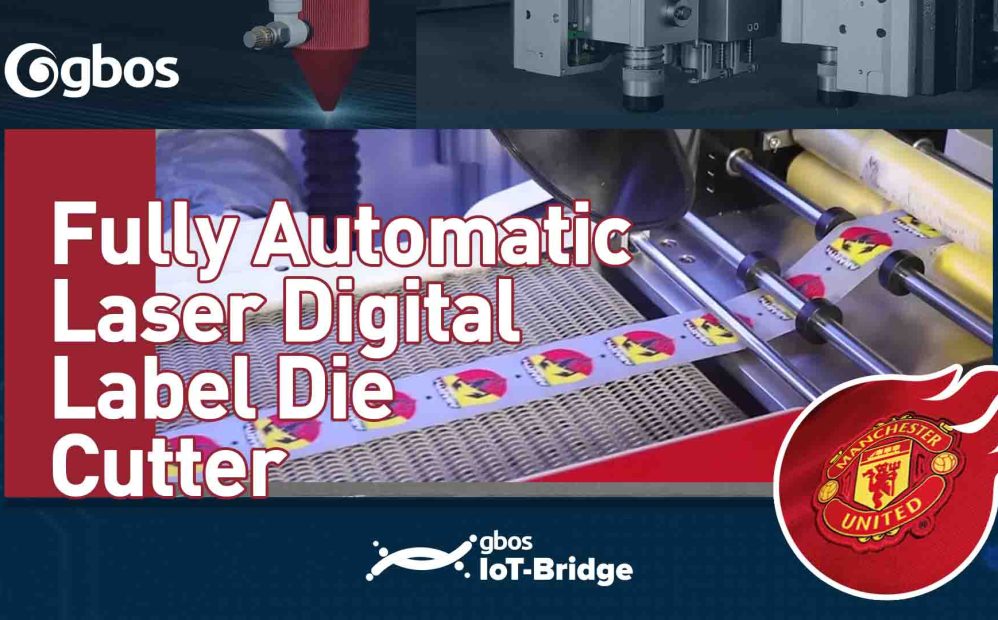

Digital Laser Die Cutting Machine

An unmanned, high-speed, intelligent, and multifunctional automatic laser digital die cutting machine.

Integrated design.

Professional roll-to-roll working platform.

Modular customization design supported.

Automated processing reduces manual labor.

Equipped with ultrasonic intelligent web guide system.

Specifications

Model

Description

Industry application

Modules

Working area

Whole power

Laser power

System requirements

Power supply

Product dimensions

Weight

Custom

Product Function

-

Automatic FeedingFeeding leveing.

Automatic FeedingFeeding leveing. -

Automatic CollectionCut-off materials.

Automatic CollectionCut-off materials. -

Automatic Rewinding of ScrapReduce labor consumption.

Automatic Rewinding of ScrapReduce labor consumption. -

Fully Enclosed Processing AreaFor safety protection, operation without contact.

Fully Enclosed Processing AreaFor safety protection, operation without contact. -

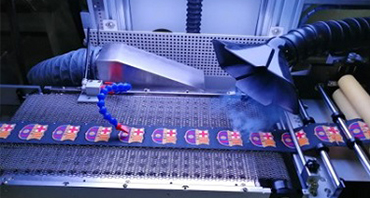

Four-dimensional Smoke SystemAvoid 2nd contamination of material and improve yellow and black.

Four-dimensional Smoke SystemAvoid 2nd contamination of material and improve yellow and black. -

All in OneLaser cutting, laser kiss cutting, laser carving, laser perforation, laser marking all in one.

All in OneLaser cutting, laser kiss cutting, laser carving, laser perforation, laser marking all in one. -

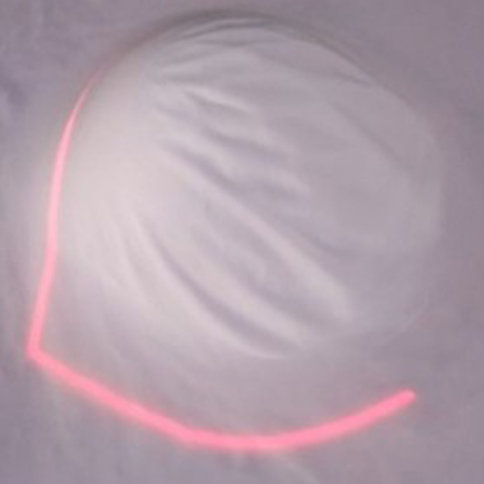

Red Light Preview and PositioningMore convenient positioning; High precision.

Red Light Preview and PositioningMore convenient positioning; High precision. -

Galvo System10 times faster than XY axis laser machine.

Galvo System10 times faster than XY axis laser machine. -

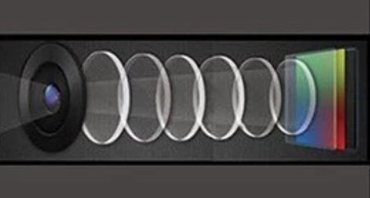

Original Optical SystemSolve ±20mm height difference, leading accuracy, thiner marking line, show perfect details.

Original Optical SystemSolve ±20mm height difference, leading accuracy, thiner marking line, show perfect details. -

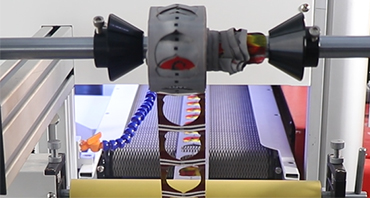

CCD Visionscan SystemCut from any angle; Automatically identify defective products; Positioning cutting for multiple design; Large size cutting.

CCD Visionscan SystemCut from any angle; Automatically identify defective products; Positioning cutting for multiple design; Large size cutting.

Expand More +

Functions & Modules

-

Realize intelligent identifying cutting along the edge, the identifying range: about 150mm*120mm.More Details

Realize intelligent identifying cutting along the edge, the identifying range: about 150mm*120mm.More Details -

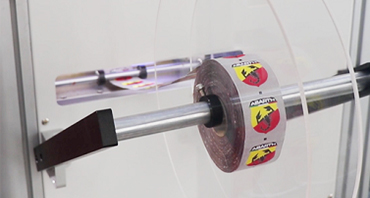

Continuously working, efficiency increased again. Materials auto feeding, easier to operate and more automated than traditional feeding.More Details

Continuously working, efficiency increased again. Materials auto feeding, easier to operate and more automated than traditional feeding.More Details -

Purify and treat the smoke and waste gas generated during the cutting processMore Details

Purify and treat the smoke and waste gas generated during the cutting processMore Details

Expand More +

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: