From April 15 to 17, Indonesia’s largest professional textile exhibition—INDO INTERTEX—was grandly held in Jakarta.

This industry event served not only as a stage for showcasing cutting-edge technologies and products, but also as a platform for envisioning the future of textile development.

GBOS Indonesia showcased a range of innovative equipment at the exhibition, engaging with industry peers from Indonesia and neighboring countries to explore the future of the textile industry together.

01 Focus on Industry Frontiers

The exhibition buzzed with energy as the GBOS booth drew significant attention from industry professionals. GBOS actively engaged with visiting customers, providing detailed introductions to its product features and advantages while patiently answering various questions. Representatives from textile enterprises in Indonesia and neighboring countries joined in-depth discussions on industry trends and shifting market demands, creating a lively and interactive atmosphere.

02 Empowering Innovation in Textile Production

At this exhibition, GBOS Indonesia presented AI digital cutting and innovative process solutions to empower the textile and apparel industry.

The VC9-1616TT Premium Line Cutter has become the center of attention due to its unique technological design. Equipped with a dual-head asynchronous cutting system, it significantly enhances cutting efficiency through an efficient collaborative working mechanism, greatly accelerating production pace. The multi-layer automatic picking and feeding system fully automates the production process, reducing reliance on manual labor while precisely controlling the feeding process. This ensures smooth material transport, effectively reduces production loss, and achieves dual optimization of both production efficiency and processing accuracy.

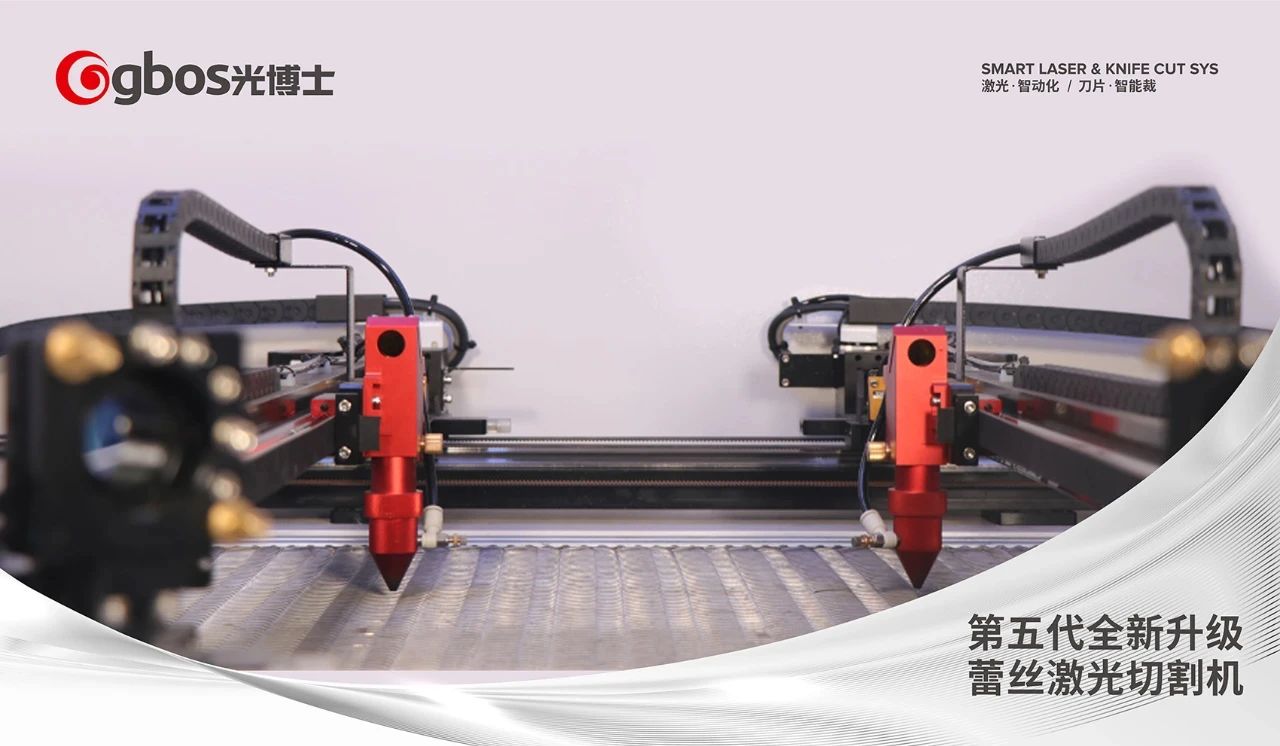

In addition, the AI VisionScan Lace Cutting Machine MS126L-TT also delivers outstanding performance. Supporting dual-roll lace simultaneous processing, it significantly boosts production efficiency. With the aid of an AI VisionScan system, it precisely identifies intricate lace pattern details, ensuring cutting accuracy at an industry-leading level. This meets the market’s diverse demands for high-quality lace processing and provides an efficient, precise solution for lace production.

In the field of textile and garment accessories processing, the XXP3-180-CCD Laser Marking and Cutting Machine shines like a brilliant star. With its advanced AI VisionScan system, it brings unprecedented technological innovation to the industry.

Whether it’s the pursuit of precise kiss cutting or complete through cutting, the creation of unique markings through laser marking, or artistic effects achieved via engraving and hollowing—this machine handles it all with ease. Even for precision perforation on white materials, it delivers outstanding performance effortlessly.

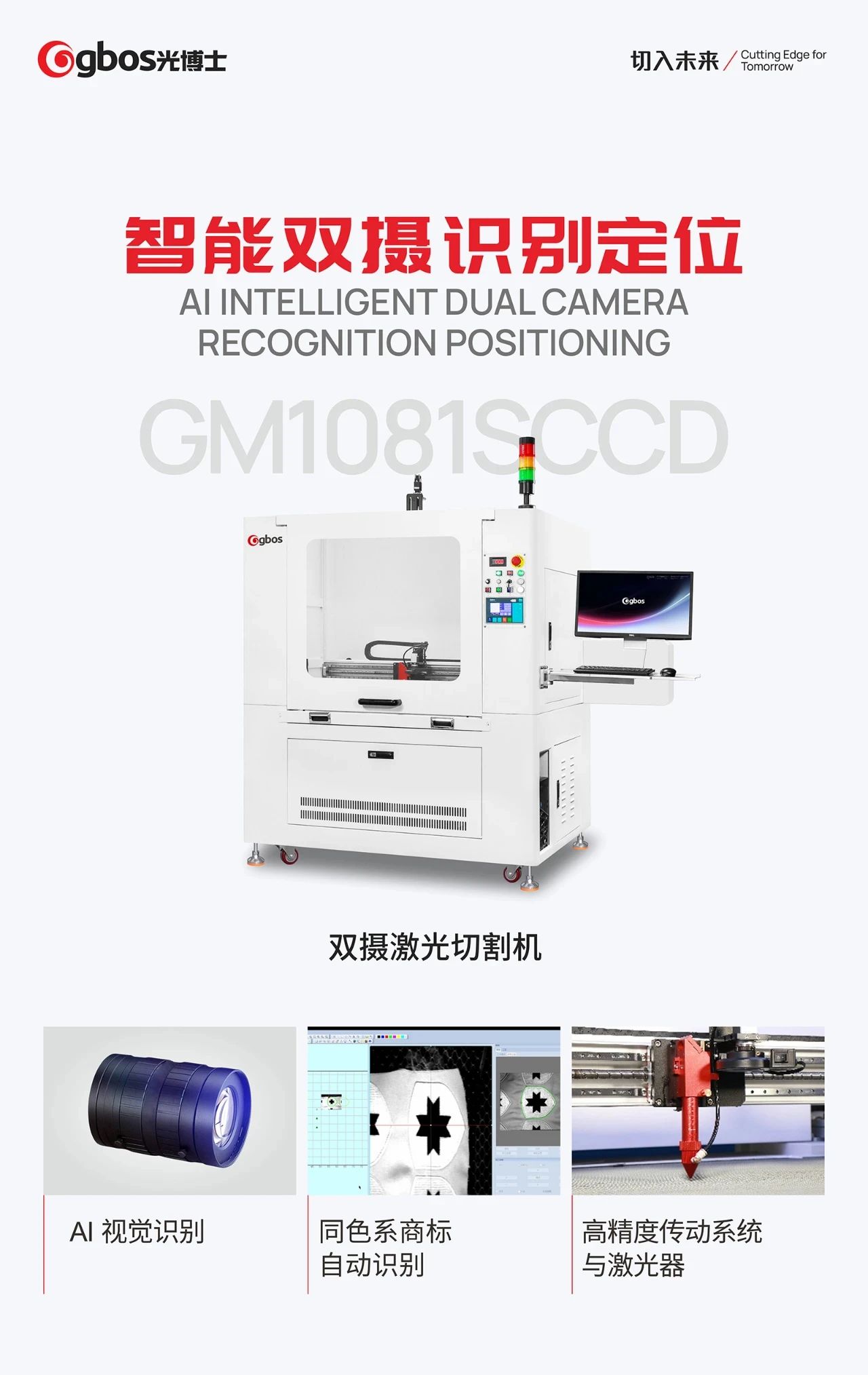

The GM1081SCCD/5.0 Same-Color Label Cutting Solution is a perfect fusion of technology and innovation. Equipped with GBOS’s latest 5.0 AI VisionScan system—like having a pair of piercing eyes—it can quickly and accurately recognize and locate same-color labels, effortlessly solving the industry challenge of same-color label positioning and cutting. Since its stunning debut in 2024, this solution has earned widespread acclaim and high praise from users at home and abroad for its outstanding performance and exceptional results.

The GNM1480T White Material Cutting Solution is dedicated to resolving persistent issues such as yellowing, blackening, and burning along the edges during the cutting of white materials. With advanced technology, it ensures flawlessly clean cut edges, providing strong assurance of product quality. As a standout in the GBOS GN laser product line, the GN series has carried extraordinary expectations since its inception, fulfilling a vital role in driving industry standards forward.

03 Driving Textile Industry Upgrades Through Collaboration

Today, Indonesian textile manufacturers are actively advancing production transformation, with growing demand for automation, intelligent technologies, and energy-efficient, eco-friendly equipment. GBOS’s participation in this exhibition aligns precisely with the development trends of Indonesia’s textile industry. With cutting-edge technology and localized service advantages, GBOS provides strong support for the intelligent transformation of textile manufacturing in Indonesia and neighboring countries.

Looking ahead, GBOS will continue to deepen its focus in the textile machinery field, driving continuous innovation in both technology and service. In partnership with industry peers, GBOS is committed to supporting Indonesia’s textile industry in moving toward a greener, more sustainable future—together writing a new chapter in the development of the textile sector.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: