Jack Ma, the leader of Alibaba Group, recently came up with the concept of “new manufacturing” at the Yunqi Conference in Hangzhou, China. And said that “new manufacturing will soon bring overwhelming threats and opportunities to the manufacturing industry of China and even the whole world”.

He believed that a successful manufacturing industry must make good use of the Internet, IOT, cloud , big data and other new manufacturing enterprises. Because enterprises that do not make good use of these new technologies will fail, not the manufacturing industry, but the backward manufacturing industry does not work, it is these not making good use of the new technology manufacturing industry does not work.

In last past few years, the assembly line in five minutes may produce 2000 pieces of the same clothes is easy, but in the furture, future five minutes to product 2000 pieces of different clothes is even more easier.

Maybe, you’ll say it’s difficult to achieve it.

Not at all~ GBOS can help you achieve it.

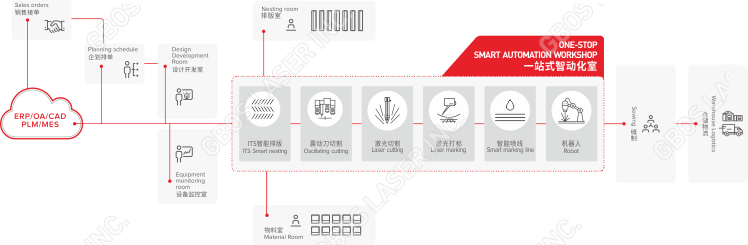

GBOS IOT system, GBOS software and technology, and laser system can help you realize intelligent production with a small amount and diversification.

Welcome to know more about GBOS~

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: