Recently, GBOS announced the official integration of the Tongyi Qianwen model series and DeepSeek’s advanced AI technology, marking a significant step forward in technological innovation, accelerated R&D, optimized internal operations, and institutional evolution. As a pioneer in intelligent manufacturing, GBOS remains at the forefront of technological advancements. This integration of AI large models will further strengthen its industry-leading position and inject new momentum into intelligent manufacturing.

01 Technology Empowerment: Accelerating R&D and Innovation

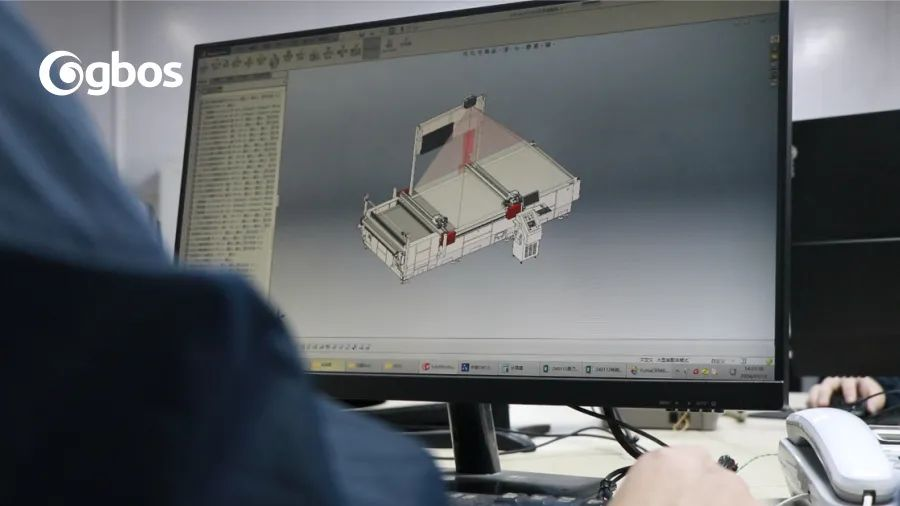

GBOS understands that technological innovation is the core driving force behind enterprise development. With the integration of Tongyi Qianwen and DeepSeek, GBOS will achieve a significant leap in R&D efficiency. In traditional R&D processes, complex experimental data, vast technical parameters, and diverse product demands often lead to long development cycles and high trial-and-error costs. The introduction of AI technology enables data analysis, algorithm optimization, and intelligent simulation to rapidly identify optimal solutions, significantly shortening the development cycle and reducing trial-and-error costs.

02 Internal Management Optimization: A New Engine for Institutional Evolution

The integration of Tongyi Qianwen and DeepSeek also provides strong support for GBOS’s internal operations and institutional evolution. Leveraging AI technology, GBOS will establish an intelligent management system, achieving a transformative upgrade from experience-driven to data-driven decision-making.

In supply chain management, AI can monitor raw material supply, production progress, and logistics in real time, optimizing resource allocation and reducing inventory costs.

In human resource management, AI will leverage data analysis to precisely match employee skills with job requirements, enhancing team efficiency. Additionally, AI-driven intelligent analysis will provide scientific insights for business decision-making, driving continuous improvement and evolution of management systems.

03 Embracing Innovation: Always Staying at the Forefront of the Industry

GBOS has always been driven by innovation. As early as 2008, it launched the first-generation AI VisionScan system, marking the beginning of a new chapter in intelligent manufacturing. In 2017, GBOS introduced the first-generation IoT Bridge system, enabling device interconnection and data sharing. In 2019, GBOS launched the first-generation AI-powered intelligent leather nesting system, further enhancing production efficiency and product quality.

The integration of Tongyi Qianwen and DeepSeek marks another significant milestone in GBOS’s journey of innovation. Moving forward, GBOS will continue to deepen the application of AI technology, exploring new frontiers in intelligent manufacturing. For example, by combining AI technology, GBOS will accelerate the iteration of the “AI Digital Cutting Center” and, with the digital capabilities of “IoT Bridge,” help enterprises optimize the entire automation process—from raw materials to design and production—advancing the management of the entire workflow.

04 Looking Ahead: Leading the New Era of Intelligent Manufacturing

The era of AI has arrived, and the integration of Tongyi Qianwen and DeepSeek has not only brought technical breakthroughs to GBOS but also injected new momentum into its development. GBOS will continue to uphold its spirit of innovation, embrace advanced technologies, and drive intelligent manufacturing to new heights.

As an industry pioneer, GBOS’s practices also provide valuable insights for other companies. Moving forward, GBOS will continue to serve as a model, driving the intelligent transformation of the industry and jointly ushering in a new era of intelligent manufacturing.

Every step taken by GBOS is a commitment to and practice of innovation. Moving forward, GBOS will continue to advance alongside technology, driving development through innovation, and creating a new chapter of brilliance in intelligent manufacturing!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: