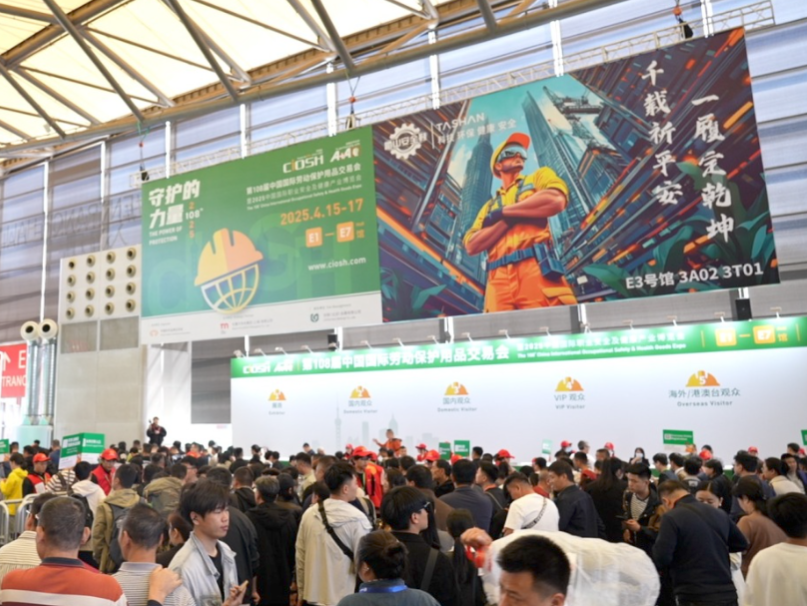

The 108th China International Occupational Safety & Health Goods Expo was held at the Shanghai New International Expo Centre from April 15 to 17, 2025. Centered around the theme “The Power of Protection,” the expo showcased a wide range of products, including personal protective equipment, workplace safety and occupational health gear, as well as emergency response technologies and equipment.

As an innovative enterprise in the industry, GBOS participated in the exhibition with its AI Digital Cutting Center solution and two newly launched machines, drawing significant attention from industry professionals.

01 Enhancing the Power of Protection with Innovative Technology

During the exhibition, the GBOS booth attracted numerous industry professionals. Its showcased AI Digital Cutting Center solution, integrating AI technology with cutting processes, demonstrated an efficient and precise cutting workflow through live demonstrations. This not only contributes to improving production efficiency and product quality, but also highlights GBOS’s achievements in technological innovation—offering valuable insights for the digital transformation of the labor protection industry.

02 Upgraded and More Powerful Technological Appeal

Masterpiece 1: Sky Blue Limited Edition — 「Gantry-style Intelligent Oscillating Knife Cutter」

The gantry-style intelligent oscillating knife cutter VC9-1665T integrates both cutting and punching functions, delivering work efficiency approximately 3 to 4 times higher than that of traditional equipment. Equipped with an oil reservoir for automatic guide rail lubrication, it simplifies maintenance. Powered by a high-performance servo motor, the machine achieves a synchronization error as low as 15ns and controls synchronization jitter within ±20ns, resulting in a performance boost of about 15% to 18%.

The integrated punching knife holder, paired with a low-noise knife head, delivers a vibration frequency of up to 300 times per second. Additionally, the built-in negative pressure waste suction system ensures a cleanliness level of over 90%. Capable of cutting a variety of regular materials—including multi-layer PU, mesh fabric, insole fabric (board), TPU, and high-elasticity flyknit—the machine offers an efficient and precise processing solution for the production of labor protection products.

Masterpiece 2: Genuine Leather Cutting Solution — 「ITS3-3012+KC1660TT-3P」

Another highlight of the exhibition was the oversized flatbed open-style digital cutting machine KC1660TT-3P, equipped with a dual-head asynchronous cutting system. This system allows for interactive cutting between the left and right work areas, enabling material collection on the left while cutting occurs on the right, significantly enhancing cutting efficiency.

The machine is suitable for projection preview positioning and cutting of various genuine leather materials, such as nubuck and split leather. It is equipped with a dual 4-punch (8 punches) optional setup, allowing the use of different punch needles to meet various hole diameter punching needs. Additionally, the device features a “negative pressure waste suction” module, ensuring a cleanliness level of over 90% after punching.

With the integration of the ITS3-3012 Intelligent Leather Nesting System, the material utilization rate can exceed 85%, making it the optimal choice for leather nesting and cutting.

03 Persisting in Innovation to Support the Development of the Labor Protection Industry

At this exhibition, GBOS showcased its technological strength and product innovation, aligning with the theme “The Power of Protection.” Through technological innovation, GBOS offers higher-quality equipment and solutions for the labor protection industry, contributing positively to the industry’s digital transformation.

In the future, GBOS stated that it will continue to focus on industry needs, persist in innovation, and develop more practical products to support the steady development of the labor protection industry, driving industry progress through technological innovation.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: