With the summer travel season in full swing, demand for travel gear such as suitcases and backpacks has surged. As tourism booms, orders for luggage products are on the rise. Today’s consumers are not only looking for durability and practicality, but also expecting higher standards in personalized design and refined quality details.

Behind the travel boom lies the urgent demand from luggage manufacturers for efficient production and precision processing.

Peak Season Challenge: A Dual Test of Efficiency and Quality

Faced with a sharp surge in orders, manufacturers are grappling with multiple challenges.

On the capacity and efficiency front, the pressure of large-scale production has fully exposed the inefficiency of traditional cutting equipment, making it nearly impossible to meet urgent delivery timelines.

In terms of production costs, rising raw material prices, coupled with significant material waste during manufacturing, have made cost control increasingly difficult.

Even when day-to-day production runs smoothly, manufacturers remain cautious about scaling up. After all, a single misjudgment in market demand could lead to unsold inventory and overstock — a looming risk like the Sword of Damocles. And when unexpected large-volume orders arrive, production systems often descend into chaos, struggling to respond with agility.

Breaking Bottlenecks in Luggage Manufacturing: Seize the Holiday Season Opportunity

With deep technical expertise and a spirit of innovation, the GBOS technical team has keenly identified the key challenges faced by the luggage manufacturing industry. In response, we have developed advanced machines that deliver both high-efficiency production and precision processing — driving a new wave of transformation across the luggage sector.

Quality Revolution in Luggage Processing

3D Five-Axis CO2 Laser Precision Cutting Machine

The GN602-3D-EP, a 3D five-axis CO2 laser precision cutting machine specially designed for curved and irregular surfaces, achieves a groundbreaking technological breakthrough that overcomes many limitations of traditional processes.

Full-surface adaptability for effortless cutting: Whether it’s the smooth curves of a suitcase, delicate embossed textures, unique inclined planes, or staggered stepped surfaces, the GN602-3D-EP delivers stable and precise cutting, perforating, and trimming with exceptional performance—making every detail flawless.

Zero-defect processing with impeccable quality: Throughout the entire manufacturing process, this machine demonstrates extraordinary craftsmanship, ensuring no color deviation, no molten edges, and no carbonization at the cut areas. It achieves ultra-fine precision cutting that imparts exceptional quality to luggage products.

Multi-axis synergy for seamless, all-angle processing: The tightly integrated X-axis, Y-axis (Y1, Y2), Z-axis, W-axis (±180° swing), and U-axis (360° continuous rotation) components form a powerful processing matrix. No matter how complex the shape of the luggage parts, the GN602-3D-EP enables full-range, flawless precision machining without any blind spots.

The Efficiency Engine for Mass Cutting

AI Intelligent Nesting System & Digital Cutting System

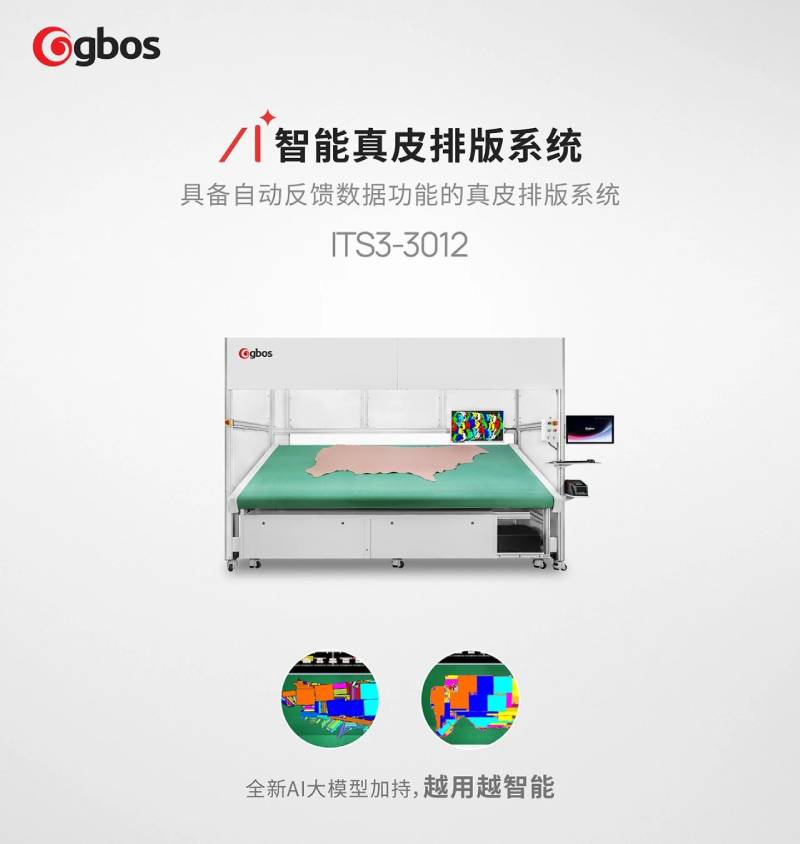

The ITS3-3012 AI Intelligent Genuine Leather Nesting System and the dual-head asynchronous oscillating knife cutting machine KC1630TT-RT-3P join forces to redefine the entire processing workflow of luggage leather and accessory fabrics through intelligent design, ushering in a new era of efficient production.

AI Empowerment, Innovation Upgrade

In May 2025, the ITS3-3012 was officially upgraded with GBOS’s brand-new AI large model. This advanced model acts like the intelligent soul of the system, bringing a qualitative leap in leather defect detection and intelligent nesting algorithms.

With the powerful AI capabilities, the system operates more smartly and efficiently, truly achieving the outstanding goal of becoming “smarter and more efficient the more it’s used.” This upgrade provides strong support for the intelligent transformation of luggage manufacturing.

Outstanding Performance, Expert in Cutting All Materials

The KC1630TT-RT-3P Genuine Leather and All-Material Cutting System, with its outstanding performance, has become a reliable partner for sustainable cutting operations. Whether tackling various types of fine genuine leather cutting or efficiently handling multi-layer cutting of regular materials, it performs effortlessly, flexibly meeting the demands of diverse production scenarios.

Intelligent Cost Reduction and Maximum Material Utilization:

Strict control over material usage from the source effectively lowers production costs, creating greater economic benefits for enterprises.

Dual Enhancement: Efficiency and Cleanliness Combined:

The perfect integration of dual-head asynchronous operation and an optional automatic waste extraction system significantly boosts cutting efficiency while maintaining over 90% cleanliness in the work area. This ensures a tidy and orderly environment, providing strong support for efficient production.

Precision and Stability: Consistent Quality Every Time:

High-precision cutting technology guarantees product consistency in mass production, effectively reducing defects. Each luggage item meets high-quality standards, satisfying the market’s stringent quality demands.

From backpack fabrics and linings to plastic molded parts, we offer a full-process, one-stop solution that perfectly handles complex and diverse order requirements — including small batches, fast delivery, and large volumes at critical time points.

Key to Winning the Peak Season: Seizing Market Opportunities Through Technology Advantages

In today’s fiercely competitive product market, the essence of competition centers on two core factors: production efficiency and product quality. GBOS’s one-stop luggage solutions, with their dual advantages of “precision processing for superior quality” and “efficient production to boost capacity,” act as a powerful catalyst for manufacturers. This enables them to achieve leapfrog growth in production capacity and stand out in the marketplace.

Amid the surging wave of consumption upgrades and the accelerating pace of technological innovation, GBOS remains steadfast to its original mission. Anchored by laser and intelligent cutting technologies, we deeply understand market demands and continuously innovate and optimize to deliver smarter manufacturing solutions that align closely with market trends and enhance competitiveness.

Partner with GBOS — and step into a brighter future together.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: