In the vibrant and energetic city, more and more people choose running as a way to release pressure and enjoy life. From the quiet park trails in the morning to the illuminated riverside walkways at night, people who love sports are everywhere.

However, for runners, a pair of suitable sneakers is crucial. It should not only meet the functional needs of running, but also be able to show fashion, trend and versatility.

In recent years, the same-color mesh material has become a highlight in sneaker design with its unique visual effect and lightweight texture. Through the fine preparation process, this material cleverly integrates patterns and colors, breaking the single image of traditional mesh and injecting new vitality into sports shoes.

PART 01

The Footwear Industry Challenge

However, in the production process of sports shoes, how to efficiently and accurately cut this same color mesh material has become a major problem for footwear industry. Traditionally, footwear industry usually use punching machines and dies for cutting, but this method is not only inefficient, but also increases the cost of labor, tooling and site management, limiting the flexibility of footwear industry to respond quickly to brand needs.

(Traditional cutting of mesh material of the same color)

PART 02

Cracking the cutting problem and improving cutting efficiency

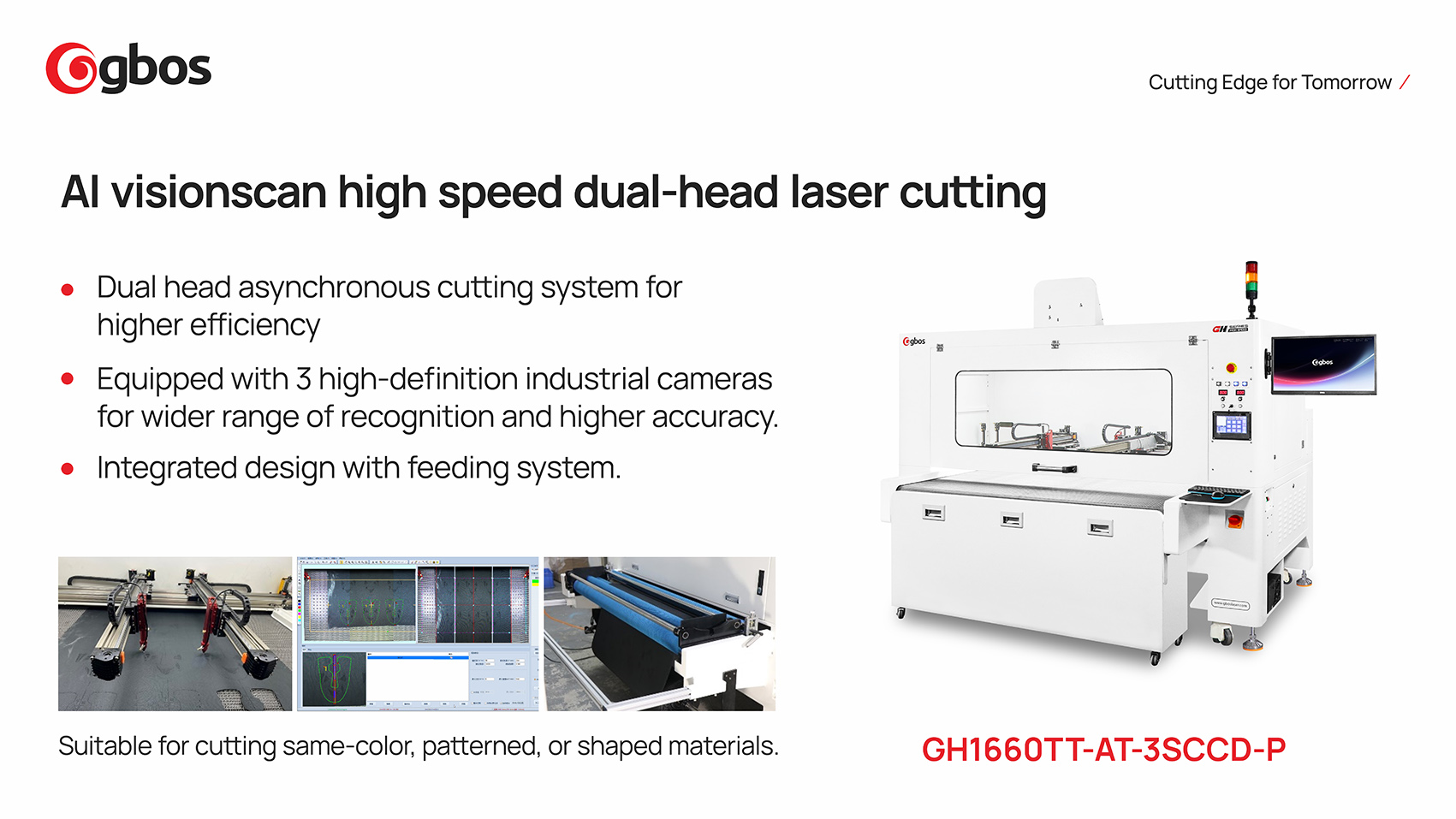

In order to reduce operation cost and increase manufacturing flexibility, we bring the AI visionscan dual-head asynchronous high-efficiency laser cutting machine (GH1660TT-AT-3SCCD-P) to footwear industry. This machine is equipped with the latest AI visionscan system, which is able to accurately locate and identify different styles of mesh materials of the same color, no matter how complex and varied the patterns are, it can achieve high efficiency and accurate cutting. Meanwhile, the addition of automatic feeding system makes the cutting process without manual laying of material by hand, which greatly improves the work efficiency. In addition, the use of projection preview positioning system makes the cutting process more intuitive and controllable.

In addition, for footwear accessories material cutting, we also bring 4-head laser footwear accessories cutting machine (GH1610F-AT), which has become the right-hand man in the production line of footwear industry with its high efficiency and versatility. Equipped with 4 laser heads and an automatic feeding system, this machine is able to cut materials synchronously, solving the problem of personnel feeding and at the same time realizing a direct multiplication of cutting efficiency. The machine is capable of cutting footwear accessories materials such as midsole fabric, TPU and PU synthetic materials with ease. In addition, with the optional scribing device, it can also complete the scribing work at the same time of cutting, further simplifying the production process and reducing costs.

We are well aware that in this competitive era, reducing costs and increasing efficiency and improving the core competitiveness of enterprises are the keys to the sustainable development of footwear industry. Therefore, we hope to provide footwear industry with more efficient and accurate cutting through these advanced solutions, thus promoting the high-quality development of the sports footwear production industry.

In the future, we will continue to devote ourselves to technological innovation and industrial upgrading, provide more high-quality equipments and services for footwear industry, and jointly promote the prosperous development of the sports footwear industry.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: