In this ever-changing world of fashion, there are always some single product as a witness of time, through the baptism of time but more and more classic – denim, is this eternal chapter of the immortal pen.

The key to evaluating whether a pair of jeans is washed or aged is the natural flow of flavor.

Unnatural washing traces, like a poor imitation, people can feel the cheap artifice at a glance; while the real natural washing of the old, the color from light to dark, the transition is natural, every wear and tear, color and even holes in the patches, as if telling the story of the wearer, and the traces of time coincide with each other.

01 windsock in the Cowboy Industry

In recent years, the trend of the denim industry has been characterized by both diversification and sustainability. on the one hand, designers are constantly exploring new possibilities for denim fabrics, from color and cut to functionality, and every innovation has injected new vitality into denim apparel.

On the other hand, as consumers become more aware of environmental protection and sustainable fashion becomes an irreversible trend, the denim industry is also looking for more environmentally friendly production methods to minimize its impact on the environment.

02 Pain Points and Challenges in Denim Manufacturing

Behind the splendor of the denim industry, there are hidden pain points that cannot be ignored. First of all, the traditional washing process is a huge consumption of water resources, each tank of washing requires a large amount of water, which undoubtedly exacerbates the tension of water resources.

Secondly, certain chemical substances used in the traditional manufacturing process not only pose a threat to the health of workers, but may also leak during the production process, polluting the soil and waters and upsetting the ecological balance.

Furthermore, the production of denim apparel is highly dependent on the experience of the workers, which not only limits the flexibility and responsiveness of mass production, but also makes it difficult to significantly increase production efficiency.

03 Revolutionary solutions: XXP5-600-2D, the green revolution in denim manufacturing

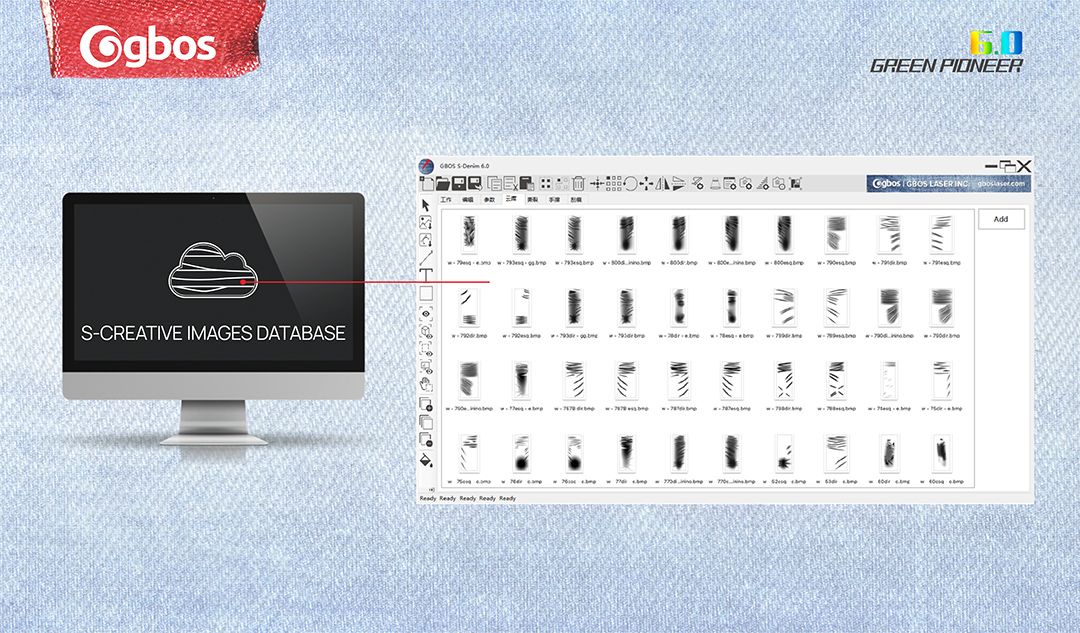

Facing these challenges, we bring XXP5-600-2D jeans scale production – process splitting preferred model. This model is equipped with S-Denim 6.0 operating system,

which can complete the complex processes of denim’s Ripper, Grind, PP-Spary, Whisker, all- printing and so on with one click, which greatly improves the production efficiency and flexibility.

What’s more exciting is that the system has tens of thousands of creative libraries in the cloud, which can be quickly downloaded and used without the need for specialized designers, greatly shortening the design and development cycle. In addition, the solution is equipped with GBOS latest advanced 3D optical system, which ensures the clarity and fineness of the processing effect. The projection preview positioning system realizes precise positioning on denim fabrics, unified standard processing, and supports online instant preview of the laser washing process.

water waste, energy consumption and chemical use, truly realizing green production. It not only helps users save valuable water resources, reduce energy consumption, but also reduces the use of chemicals, making the production of denim more standardized and environmentally friendly.

Most importantly, this laser denim washing solution fundamentally solves the problems of water waste, energy consumption and chemical use, truly realizing green production. It not only helps users save valuable water resources, reduce energy consumption, but also reduces the use of chemicals, making the production of denim more standardized and environmentally friendly.

04 Calling for a green future, building an ESG vision together

In this era of pursuing sustainable development, the denim industry, as an important part of the fashion industry, should shoulder the important responsibility of protecting the environment and promoting the harmonious development of society. We believe that by adopting modern solutions such as XXP5-600-2D, the denim industry can move towards a healthier and greener path and contribute to the realization of ESG (Environmental, Social and Corporate Governance) goals.

Let’s work hand in hand to promote the transformation and upgrading of the denim industry, so that every pair of jeans becomes a bridge connecting the past and the future, telling a moving story of fashion and responsibility.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: