As the automotive industry experiences slower growth, cost reduction and efficiency improvement have become critical for suppliers to remain competitive. In this new normal, companies must restructure their strategies and operational models to overcome production challenges while seizing emerging opportunities.

The acceleration of electrification and the upgrade of automotive interiors are driving a major industry transformation. Autonomous driving, new energy, and connected technologies are continuously reshaping the supply chain landscape. Leading companies are boosting factory efficiency through technological innovation—strategic upgrades of manufacturing bases are becoming essential to stay competitive in the digital era.

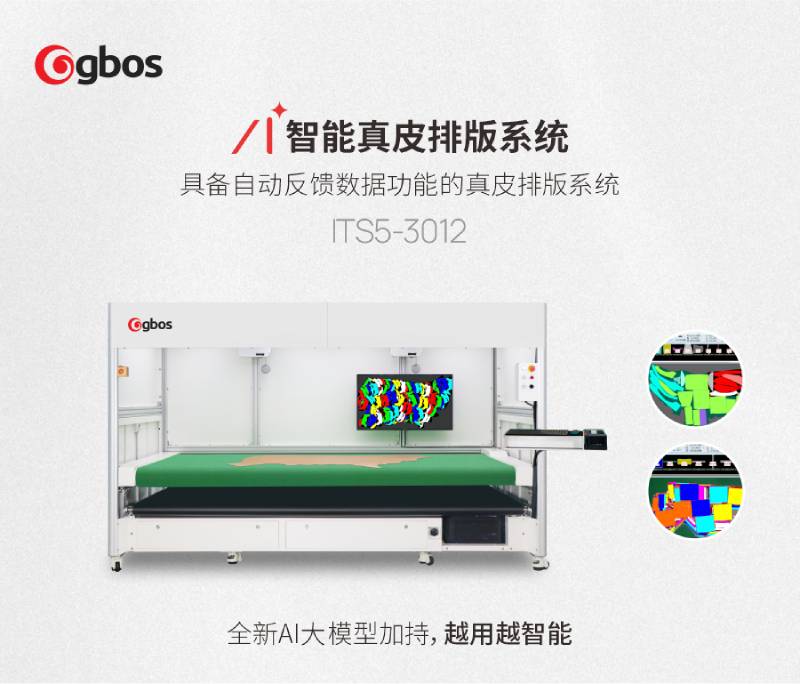

Smart Nesting Unlocks New Levels of Leather Utilization

In the fast-evolving automotive market, premium car seats start with precision leather cutting. Traditional manual nesting relies heavily on experience and often results in low material utilization. The GBOS ITS5-3012 Intelligent Leather Nesting System is transforming this process, bringing automation and efficiency to the forefront.

Backed by GBOS’s deep expertise in automotive interior and exterior manufacturing, the Intelligent Leather Nesting System leverages years of algorithm optimization to deliver highly efficient nesting, significantly reducing leather waste compared to manual operations. Equipped with a 40MP industrial camera, it accurately captures leather contours and automatically stitches multiple images, enabling continuous multi-piece nesting. This fully resolves the time-consuming and error-prone nature of manual work—laying a solid foundation for smart manufacturing while ensuring consistent quality.

Efficient Cutting for Enhanced Production Efficiency

While precise nesting lays the foundation, efficient cutting is equally critical. The KC3060TTX2-4P Dual-Station Digital Leather Cutting Machine, paired with the ITS5-3012 Intelligent Nesting System, delivers a high-efficiency leather cutting solution tailored for automotive seat manufacturing.

Designed specifically for automotive interior leather cutting, the machine features a dual-head asynchronous cutting system. Combined with a projection preview positioning system, it provides real-time visualization of part placement on the leather, ensuring optimal material utilization and cutting accuracy.

The dual-station alternating operation breaks the traditional cutting “waiting bottleneck”—while cutting occurs on the left station, the right station simultaneously collects materials; when the right station is cutting, the left is ready with new leather. Seamlessly integrated with the ITS5-3012 nesting data, this enables effortless 24/7 continuous batch production, significantly shortening delivery cycles.

Fine Craftsmanship: Elevating Seat Texture and Personality

If intelligent nesting and cutting address the challenges of efficiency and material saving, then laser technology adds texture and individuality to automotive seats. The XXP4.2-180 laser perforation and embossing solution demonstrates powerful capabilities in this area.

With its advantages of high speed, high precision, and cutting-edge innovation, it performs a series of intricate processes on genuine leather surfaces:

The high-speed laser ventilation perforation process produces smooth, evenly distributed holes, ensuring seat breathability while avoiding the rough edges common with mechanical punching. Laser embossing technology creates three-dimensional textures, clearly rendering everything from simple brand logos to intricate patterns. The 3D textured personalized design adapts seamlessly to the seat’s curved surfaces, allowing patterns to naturally follow the seat contours—delivering superior visual depth and tactile finesse that surpass traditional methods.

From meticulous material optimization and precise, efficient cutting to delicate, dynamic craftsmanship, GBOS’s digital solutions are transforming automotive seat manufacturing from an experience-based process to a data-driven one.

GBOS not only helps manufacturers reduce costs and increase capacity but also meets users’ demands for seat comfort, aesthetics, and personalization through consistent quality and flexible craftsmanship. In today’s automotive industry pursuit of the ultimate driving experience, such digital intelligent manufacturing may well be the key to unlocking the future of seat design.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: