In the manufacturing sectors of shoes, luggage, automotive interiors, and sofa furniture, enterprises are increasingly challenged by high labor costs, low efficiency, and unstable precision in mass production. These persistent pain points have become major “stumbling blocks” for businesses striving to gain a competitive edge in the market.

From the heavy reliance on skilled workers for sorting cut pieces to inefficient cutting processes that can’t keep up with order demands — and from excessive leather waste driving up costs to cluttered work areas caused by leftover materials — these issues not only restrict production capacity but also hinder overall competitiveness.

01. Bottlenecks in Traditional Mass Production

In the shoe manufacturing industry, traditional production lines require significant manual labor to sort and handle cut pieces. Each skilled worker can only process a limited volume daily, and fatigue from long hours often leads to sorting errors, resulting in costly rework in later stages.

In luggage production, manual positioning during leather cutting introduces variability, as different workers have distinct operation habits. This inconsistency leads to inaccurate cuts, material waste, and additional costs to correct defective products.

Furthermore, the absence of efficient marking systems in traditional workflows makes it difficult to identify and match cut pieces with subsequent processes. This slows down production cycles and increases the risk of delayed deliveries.

02. Full Automation: Driving Efficiency, Precision, and Cost Reduction

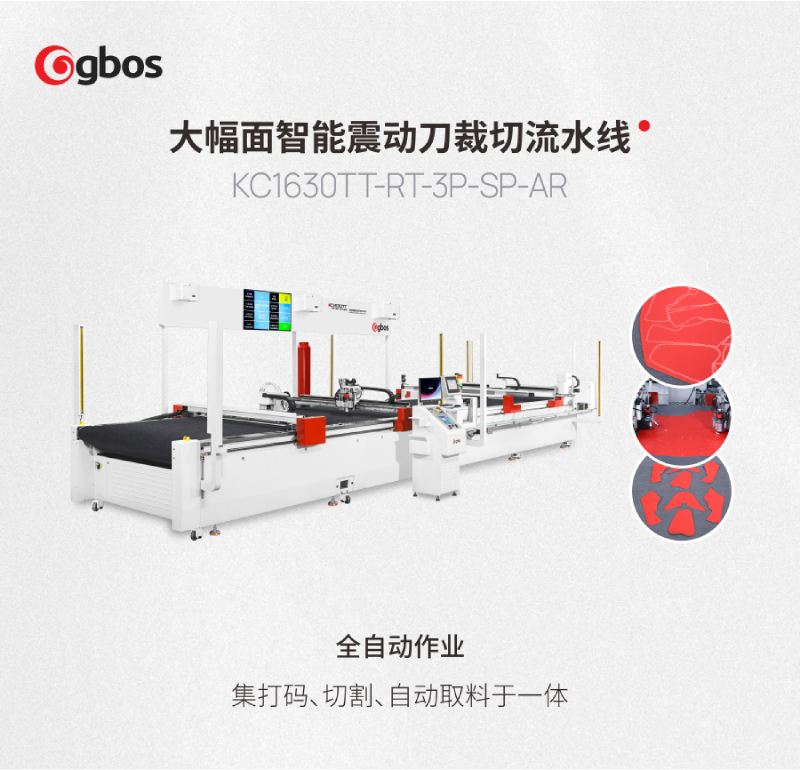

To address these pain points, GBOS has introduced the KC1630TT-RT-3P-SP-AR automatic material handling and collecting line — an integrated solution combining coding, cutting, and automated material handling. The system delivers comprehensive automation from four key dimensions: efficiency, cost, precision, and cleanliness.

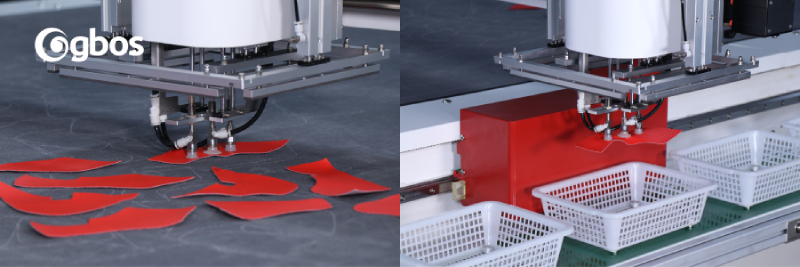

Full-process automation saves labor and reduces errors

Equipped with an automatic pairing and material-handling system, the equipment precisely manages the entire process. After cutting, materials are automatically collected without the need for manual sorting or handling.

Compared with traditional manual lines, a single KC1630TT-RT-3P-SP-AR production line can save approximately two workers, significantly reducing labor costs while avoiding sorting errors and minimizing rework.

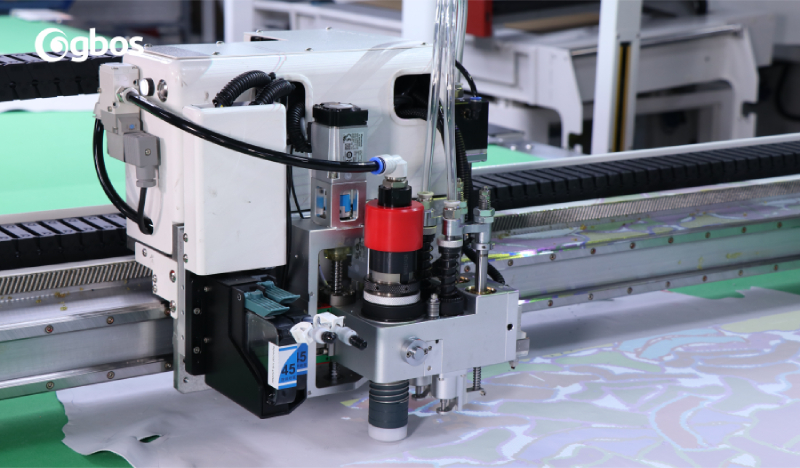

Dual-head asynchronous cutting + waste suction for double efficiency and cleaner workspace

The dual-head asynchronous cutting system allows both cutting heads to operate independently, doubling output compared to single-head equipment. This high-efficiency design easily meets the demands of large-scale production, making it ideal for high-frequency cutting scenarios.

Meanwhile, the waste suction system maintains over 90% cleanliness in the work area, eliminating the need for dedicated cleaning staff and ensuring a tidy, safe, and efficient workspace.

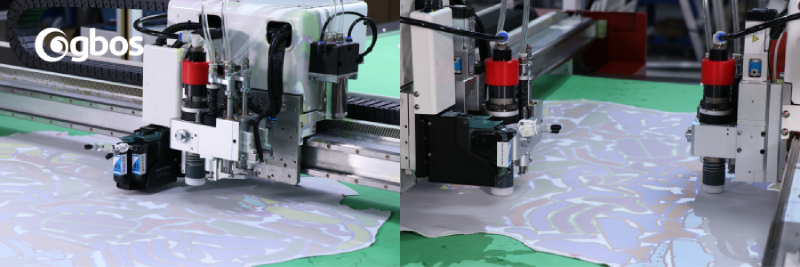

High-precision coding for perfect process coordination

The equipment features an inkjet spray coding system that automatically marks “flow codes” onto materials before cutting. The marks are even, clear, and ghost-free, helping workers easily identify and pair parts in later processes.

It supports multiple ink types — including fluorescent, permanent, water-based, neutral, and UV inks — meeting the diverse marking requirements of various materials.

Additionally, the system can seamlessly integrate with GBOS’s proprietary AGV mobile robots, enabling smarter transportation and logistics management within the production line.

03. Empowering Multiple Industries and Opening a New Era of Intelligent Production

As industries increasingly emphasize efficiency, cost control, and product precision, automation has become the cornerstone of modern manufacturing transformation.

The KC1630TT-RT-3P-SP-AR, with its fully automated workflow, not only resolves long-standing issues of labor dependence and inefficiency but also fulfills the industry’s growing demand for high-precision cutting and clean production environments.

Looking ahead, GBOS Laser will continue to drive technological innovation, empowering enterprises to achieve cost reduction and efficiency gains through automation. By embracing intelligent production, companies can enhance their competitiveness in mass manufacturing and deliver higher-quality products to the global market.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: