In today’s era of technological innovation and AI-driven production, the industrial manufacturing sector is experiencing a revolutionary transformation. This transformation focuses on intelligent, automated, and data-driven production models that not only significantly boost productivity but also spark innovation and drive upgrades across the industry.

Particularly in the field of flexible manufacturing, the application of AI VisionScan technology has become a key force in replacing manual identification, making various processes more intelligent and precise. This effectively reduces labor costs and promotes the transition from flexible manufacturing to smart manufacturing.

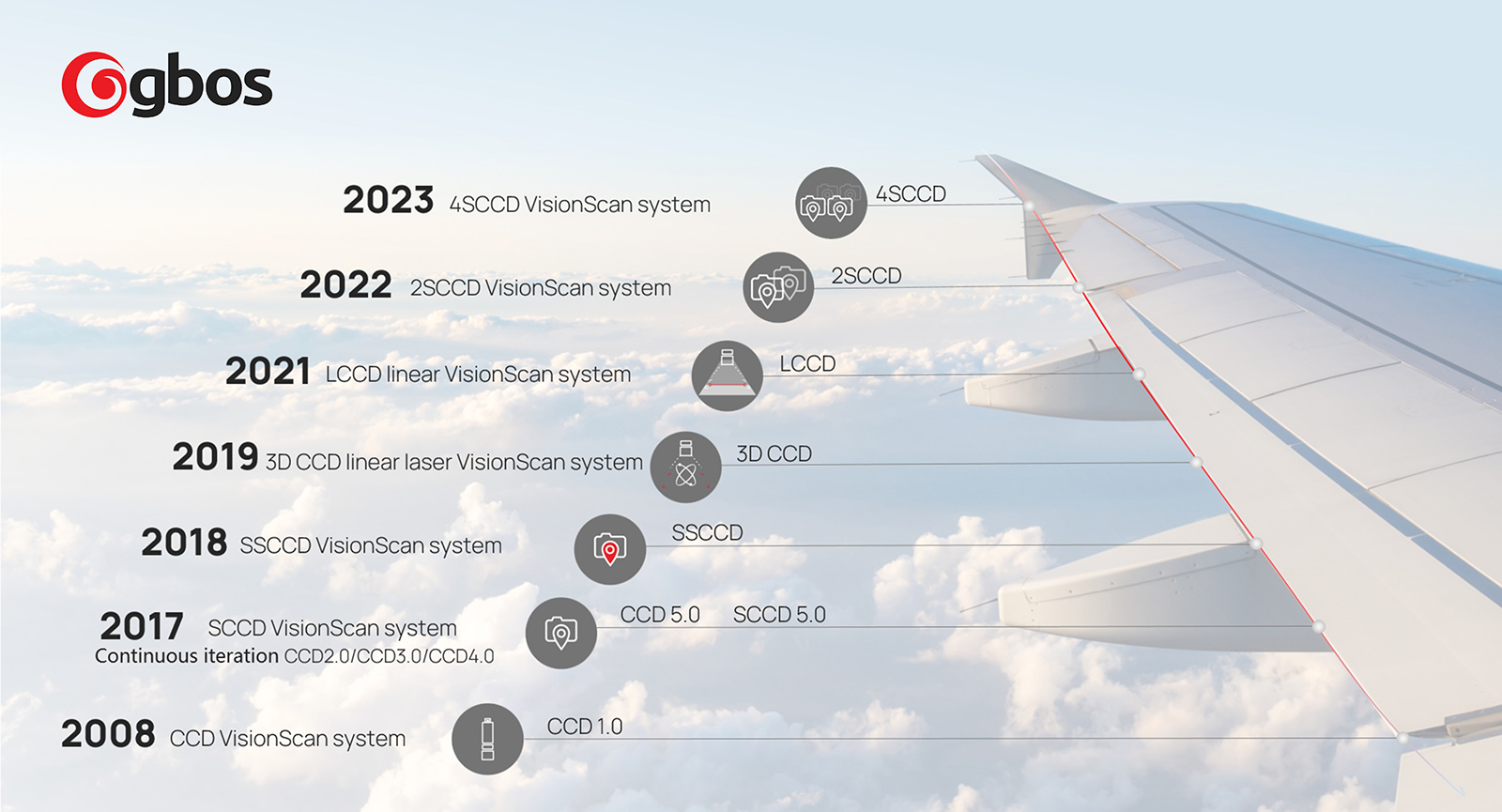

16 Years of AI VisionScan Technology Accumulation

GBOS’s emphasis on this technological transformation began in 2008 when we took the first step in developing VisionScan technology. After 16 years of technological accumulation and continuous innovation, we have advanced VisionScan technology to the fifth generation (CCD 5.0). This technology not only theoretically achieves an “AI VisionScan accuracy of ±0.1mm” but also demonstrates tremendous value in practical applications.

It has been widely applied in industries such as footwear, apparel, and garment accessories, facilitating the production and processing of same-color mesh fabrics, digitally printed materials, and various types of trademarks, thereby solving many production challenges for users.

The “Eye of Wisdom” in the Garment Accessories Industry

When discussing the successful application cases of GBOS AI VisionScan technology, AVERY DENNISON undoubtedly stands out as a model in the garment accessories industry. The AVERY DENNISON Group adheres to the philosophy of “optimizing labor and supply chain efficiency, reducing waste, promoting sustainability, and better connecting brands with consumers.”

This philosophy aligns perfectly with GBOS’s vision. Whether in the remarkable achievements in smart manufacturing or through AI VisionScan technology, replacing manual identification of complex patterns, achieving high-precision edge cutting of woven labels and various types of trademarks, thereby reducing employees’ workflow and fatigue, GBOS’s customized AI VisionScan solutions have won the trust of AVERY DENNISON.

The “Eye of Wisdom” in Footwear Manufacturing

In the footwear industry, GBOS’s AI VisionScan technology also shows outstanding application potential. For digitally printed materials, GBOS provides AI edge recognition and cutting solutions that can accurately identify and track material edges. Even the most complex patterns and color variations can be cut with precision. This application effectively solves the issues of pattern misalignment and uneven edges that may occur in traditional cutting processes, significantly improving the accuracy and aesthetics of the finished shoe uppers.

For same-color mesh materials that were previously difficult to distinguish manually, the AI VisionScan system can now sensitively capture and accurately identify material positioning points for high-precision cutting.

Additionally, in the secondary outer cutting process, the application of AI VisionScan technology, through dual/four-vision positioning systems working synchronously, greatly enhances production efficiency while ensuring processing precision and consistency.

The marking process after cutting also requires the support of AI VisionScan systems, which can automatically locate and match cutting materials based on the graphic files, achieving multi-shape and any-angle simultaneous positioning and cutting.

In practical applications, GBOS’s AI VisionScan technology has become an indispensable technical support in the production process of the flexible manufacturing field. As market demands continue to evolve, we will continue to develop and innovate AI VisionScan technology according to the needs of users in various industries, expanding its application in broader fields and promoting the manufacturing industry towards more efficient and intelligent development.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: