From March 25-27, 2025, the 20th China (Shenzhen) International Brand Underwear Fair (SIUF) will be grandly held at the Shenzhen Futian Convention and Exhibition Center.

With 20 years of technological expertise and a spirit of innovation, GBOS made a stunning appearance with the AI Digital Cutting Center, bringing a digital technology feast to the underwear industry and empowering enterprises for high-quality development.

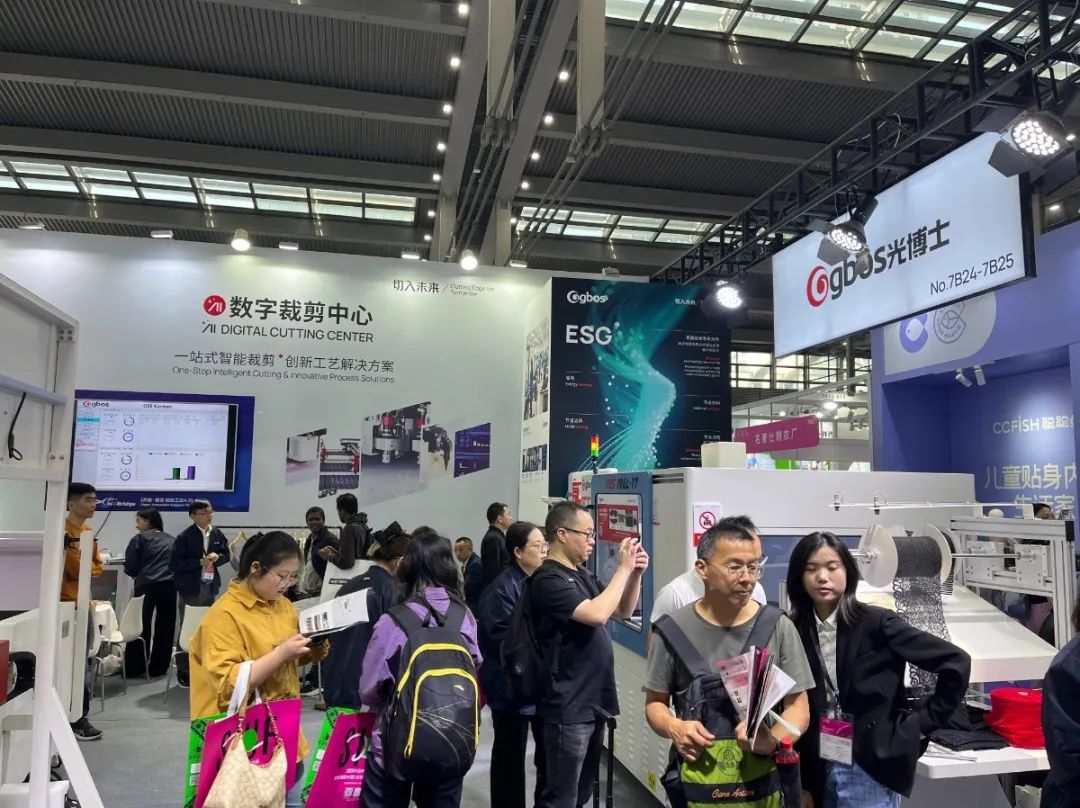

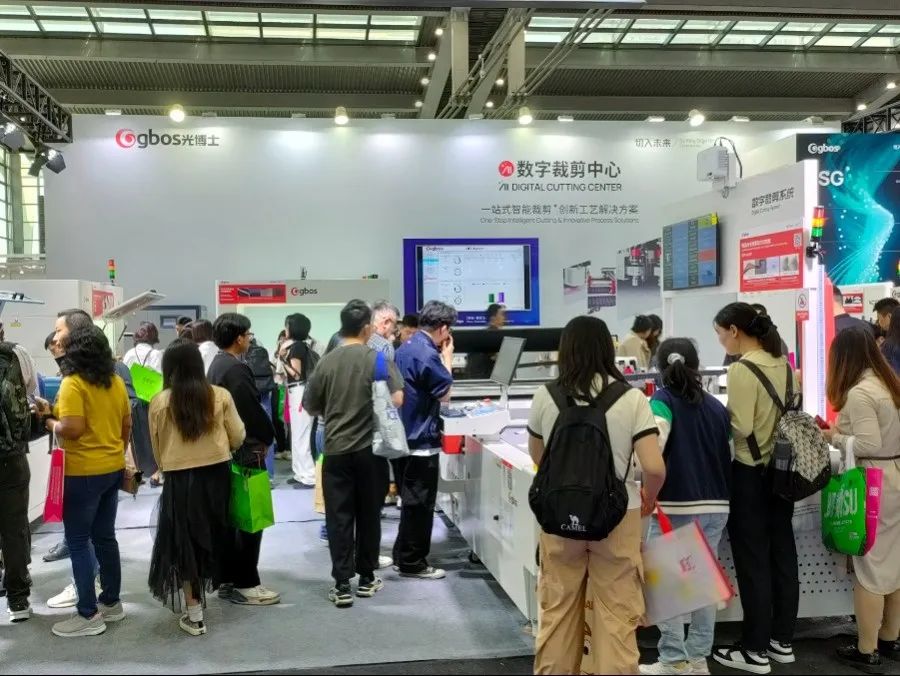

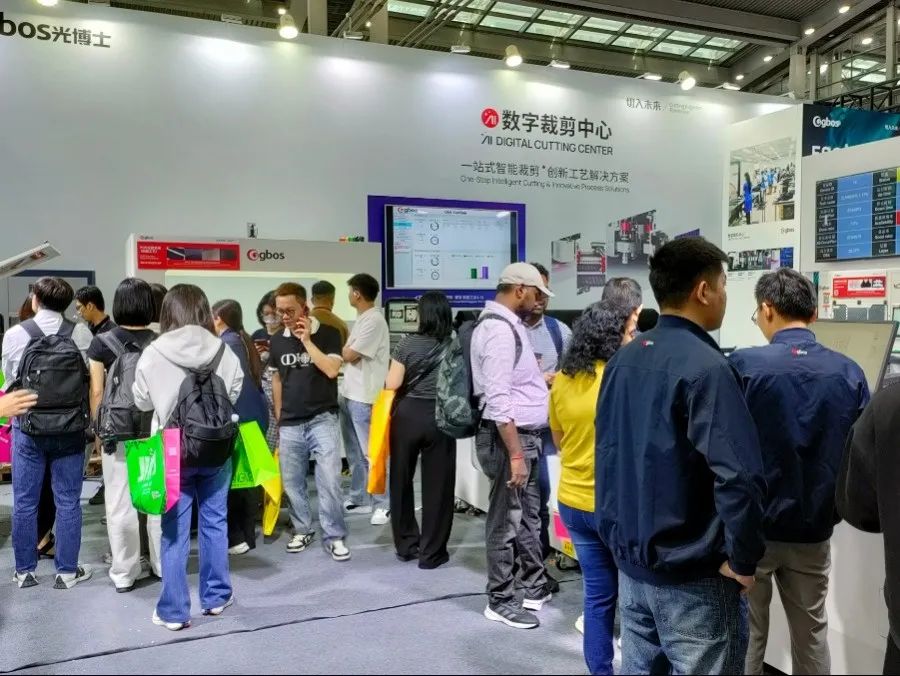

01 A Smart Manufacturing Magnet That Draws the Crowd

During the exhibition, the GBOS booth was packed with visitors, attracting underwear manufacturers and industry experts alike. Enthusiastic about GBOS’s digital technology solutions, they engaged in in-depth discussions and exchanges. Many expressed that GBOS’s innovations not only enhanced production efficiency but also addressed long-standing manufacturing challenges, earning high praise for its cutting-edge capabilities.

A lingerie manufacturer from Chaoshan signed an intent agreement on the spot after experiencing the technology, stating, “We have evaluated similar equipment from Germany and Italy, and GBOS has found the perfect balance between precision and cost.” According to preliminary on-site statistics, multiple companies scheduled factory visits after the exhibition to further explore collaboration details.

This exchange not only showcased GBOS’s technological strength and innovation but also provided valuable insights into market demands and industry trends, laying a solid foundation for future product development and market expansion.

02 Digital Technology Reshaping the Industry DNA

GBOS’s AI Digital Cutting Center became the highlight of the exhibition.

Among them, the Non-Yellowing Laser Cutting System ensures perfect cutting edges for materials prone to scorching and yellowing, significantly enhancing product quality. Additionally, the High-Precision Low-Layer Mass Production Cutting System and Fabric Edge Trimming Solution greatly improve production efficiency, reduce material waste, and expand creative possibilities for underwear design.

The Intelligent PUR Seamless Dispensing System, equipped with AI Vision Guidance Technology, achieves an automated and intelligent dispensing process, significantly improving production efficiency and precision. The Laser Non-Contact Marking Technology allows for damage-free labeling on elastic materials, ensuring clear markings while preserving the material’s original elasticity and comfort. Additionally, the 3D Five-Axis Cutting System can precisely handle complex shapes, meeting the market demand for personalized and customized underwear.

03 Digital Empowerment, Reaching New Heights

Looking to the future, GBOS will continue to uphold the principles of “Innovation, Intelligence, and Efficiency”, further deepening its focus on digital technology to provide more intelligent solutions for the underwear industry. We will increase R&D investment, driving the widespread application of laser technology, AI technology, and automation in underwear manufacturing, helping enterprises achieve full automation, intelligence, and efficiency in their production processes.

At the same time, GBOS will actively collaborate with global underwear companies to drive the transformation of the industry from “manufacturing” to “intelligent manufacturing.” With digital technology as the engine, we will help the underwear industry enhance product quality, reduce production costs, and strengthen market competitiveness. We believe that with the empowerment of digital technology, China’s underwear industry will step onto the international stage and achieve higher-level development.

GBOS is eager to join hands with colleagues in the underwear industry to create a bright future together!

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: