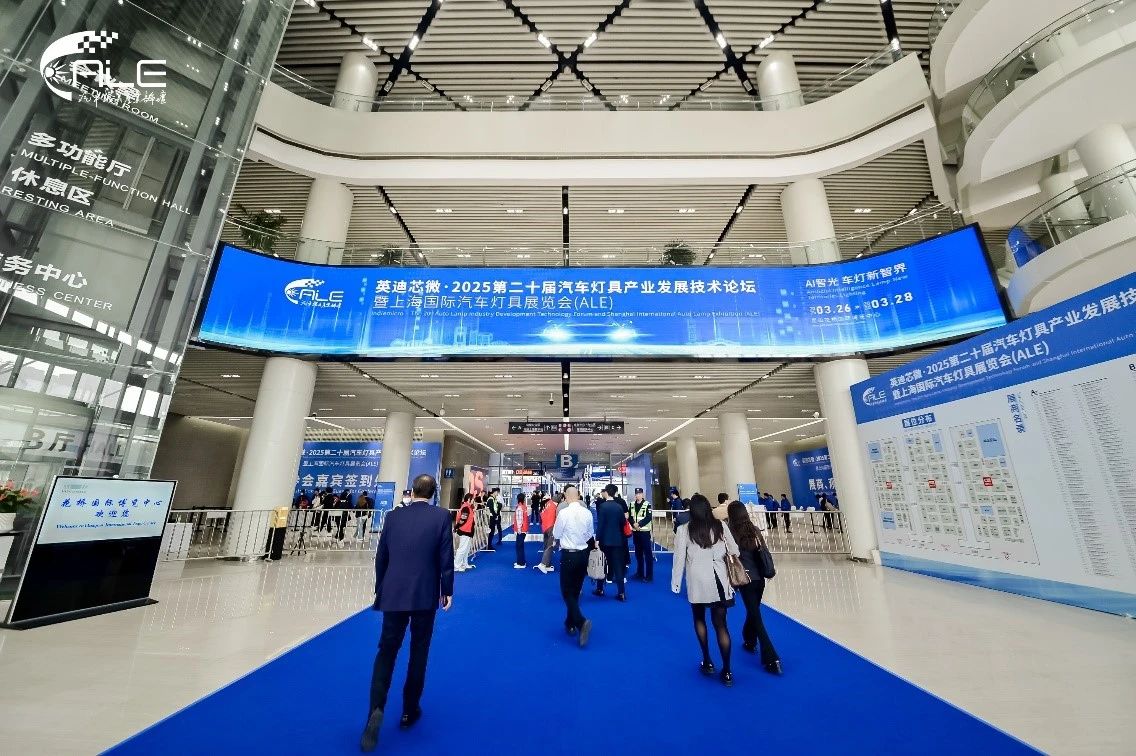

At the vibrant end of March 2025, a grand gathering of automotive industry innovation—the 20th Automotive Lighting Industry Development Technology Forum & Shanghai International Auto Lighting Exhibition (ALE)—brilliantly commenced at the Huaqiao International Expo Center in Kunshan, Jiangsu.

This time, GBOS took the stage as an industry leader, showcasing its cutting-edge one-stop laser and automation solutions for the automotive sector. Not only did it illuminate the exhibition, but it also painted a grand vision for the intelligent evolution of automotive exterior part processing.

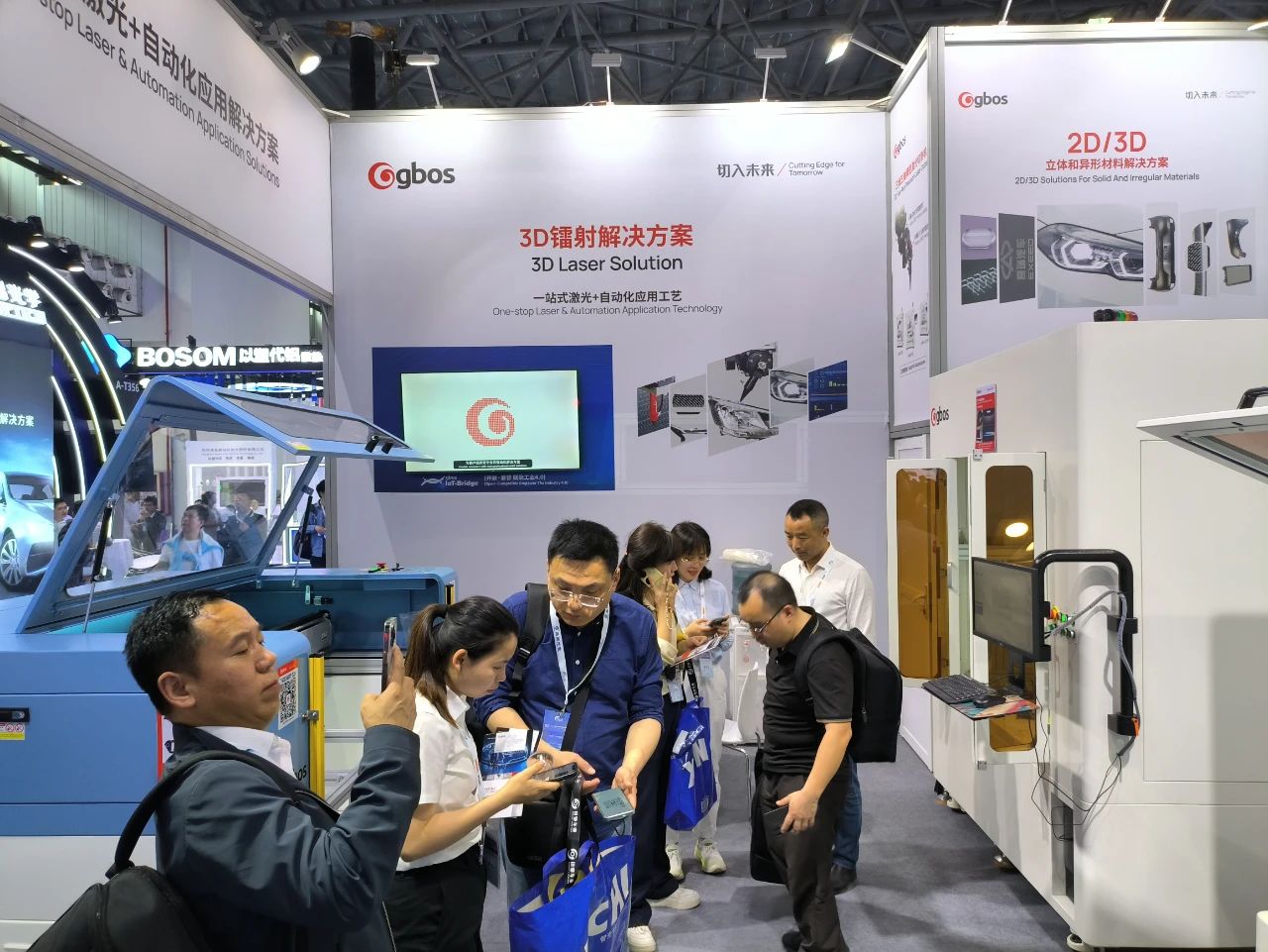

01 Turning the Tech Booth into the Industry’s Spotlight

Over the three-day exhibition, the GBOS booth was bustling with visitors as automotive industry professionals gathered, captivated by GBOS’s groundbreaking innovations. The seamless integration of advanced laser cutting technology and precision automation equipment showcased excellence in every detail. Attendees immersed themselves in this technological feast, exploring the limitless possibilities of the industry’s future.

A representative from an automotive parts company, after experiencing the solutions firsthand, praised, “The professionalism and innovation of these solutions have provided me with new insights and possibilities, allowing me to see the future of the industry.” During the exhibition, many companies expressed strong interest in collaborating with GBOS, with several already reaching preliminary cooperation agreements to explore further details.

A representative from an automotive parts company, after experiencing the solutions firsthand, praised, “The professionalism and innovation of these solutions have provided me with new insights and possibilities, allowing me to see the future of the industry.” During the exhibition, many companies expressed strong interest in collaborating with GBOS, with several already reaching preliminary cooperation agreements to explore further details.

02 Ecosystem Co-Building: From Solution Provider to Industry Enabler

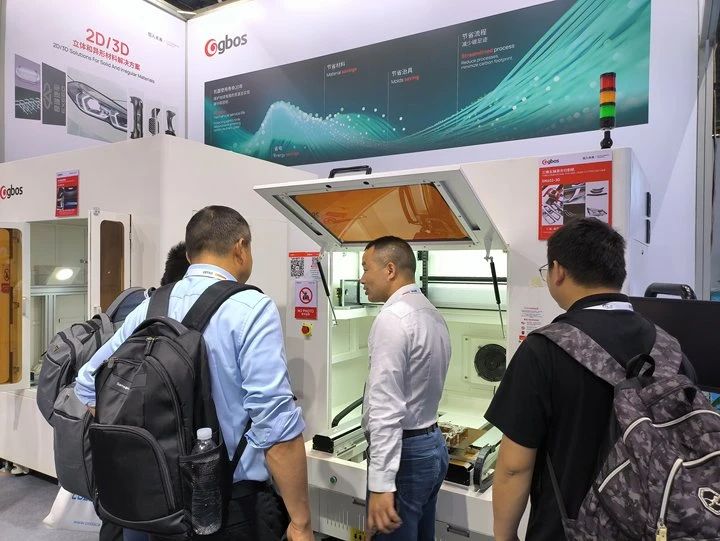

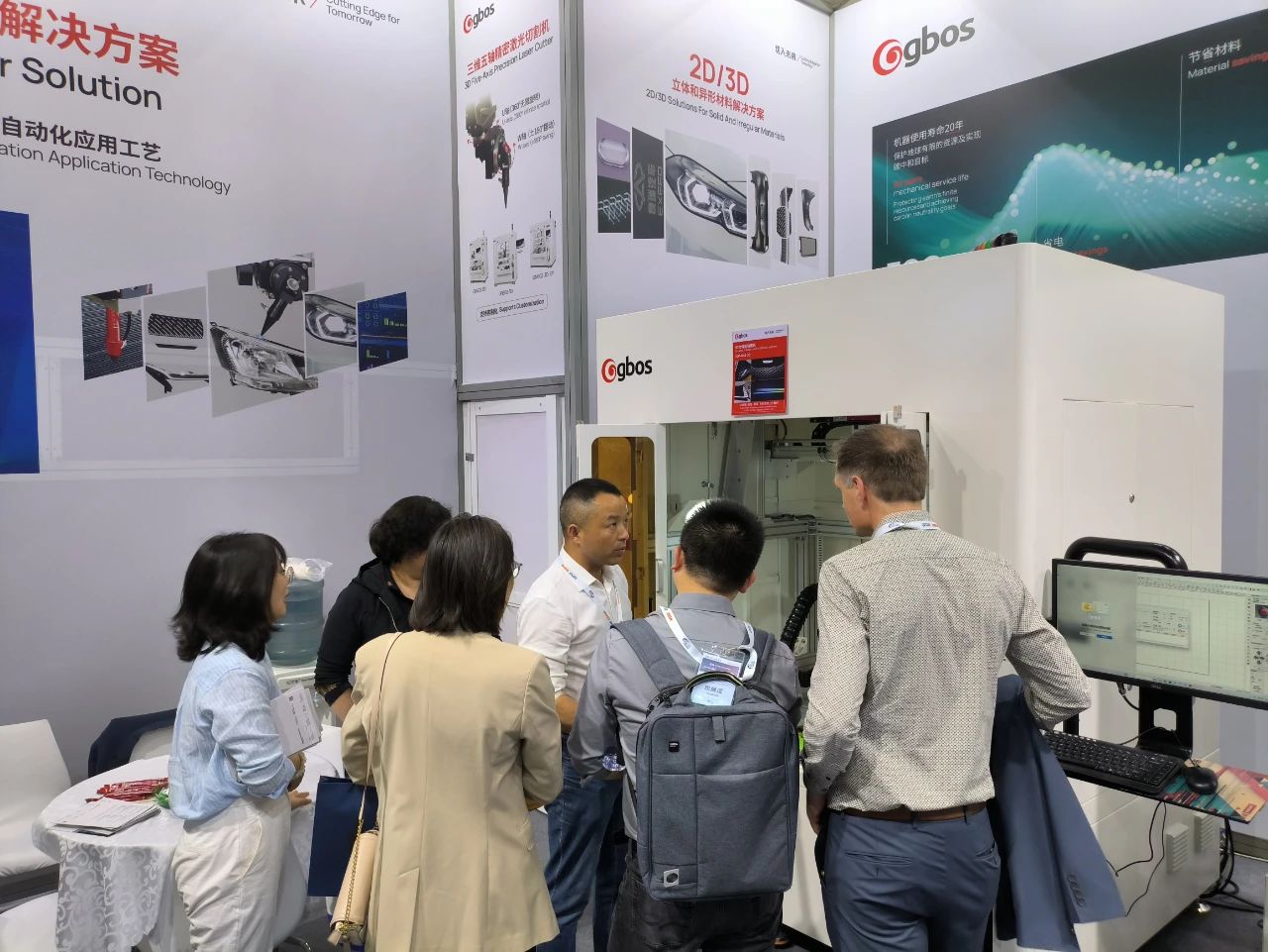

GBOS showcased a range of cutting-edge technologies and equipment, highlighting its unique advantages in automotive exterior part processing. The star exhibit, the 3D five-axis precision laser cutting machine, impressed with its outstanding performance, efficiently handling complex shapes, 3D curved surfaces, and varying height differentials in automotive exterior part cutting and trimming. Whether for headlights, lampshades, or interior and exterior plastic components, this machine ensures precise processing, significantly enhancing production efficiency and product quality stability. By delivering superior accuracy and performance, GBOS empowers automotive parts manufacturers to stand out in an increasingly competitive market.

At this grand industry event, GBOS not only showcased its technological prowess and innovative achievements but also set a new direction for the future of automotive exterior part processing. Looking ahead, GBOS will continue to deepen its expertise in digital technology, increasing investment in laser technology, AI, and automation. Committed to delivering smarter, more customized solutions for the automotive industry, GBOS strives to drive the industry’s transformation from traditional manufacturing to intelligent manufacturing.

GBOS looks forward to strengthening collaboration with global automotive industry partners to explore new technologies and applications together. With a shared vision for innovation, GBOS is committed to delivering more groundbreaking solutions in the future, driving the high-quality development of the automotive interior and exterior industry.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: