From March 17 to 18, the Vietnam & ASEAN Footwear Summit grandly commenced and successfully concluded in the vibrant and opportunity-filled city of Ho Chi Minh.

As a premier regional footwear industry event, the summit served as a bridge connecting global footwear elites. It attracted industry leaders, top technical experts, and outstanding representatives from all sectors of the supply chain across multiple countries. With its increasing international presence and industry influence, the event reached new heights, continuously injecting innovation and momentum into the global footwear industry’s development.

During the summit, representatives from footwear associations in Vietnam, Indonesia, Cambodia, and other regions took the stage to share professional insights and in-depth analysis. They explored the complexities of global footwear trade, the potential impact of tariff barriers, and the disruptive transformations brought by cutting-edge technologies such as artificial intelligence. These topics are closely tied to the growth of export and global expansion enterprises, sparking intense discussions and deep exchanges among attendees—like a stone cast into a calm lake, igniting a surge of ideas and innovation.

As a pioneering leader in flexible intelligent manufacturing, GBOS was invited to shine at the summit in both guest and sponsor roles, showcasing its outstanding achievements and profound industry influence.

In a key segment of the summit, a GBOS industry consultant delivered a keynote speech titled “How AI Digital Cutting Centers Empower Traditional Manufacturing.” With deep expertise and extensive practical experience, the consultant provided in-depth insights into how one-stop intelligent cutting and innovative processes are reshaping the traditional footwear value chain. Through precise analysis of professional case studies and robust data support, the presentation offered a forward-thinking yet practical technological vision, delivering a compelling intellectual experience to over 200 industry elites in attendance.

GBOS’s AI Digital Cutting Center is the culmination of years of expertise in flexible intelligent manufacturing. Integrating advanced AI technology, it enables high-precision cutting operations, significantly enhancing production efficiency and product quality. Its innovative processes not only optimize workflows and reduce costs but also provide the unique advantage of high performance at a competitive price. This breakthrough empowers traditional manufacturing with renewed vitality in the digital era.

GBOS regards the ASEAN market as a key pillar of its strategic expansion. Leveraging its expertise in flexible intelligent manufacturing, GBOS actively contributes to the region’s footwear industry by providing cutting-edge technological support and implementing localized services. With a strong commitment to empowering businesses, GBOS strives to accelerate their digital transformation and industrial upgrading, driving the industry toward a smarter and more advanced future.

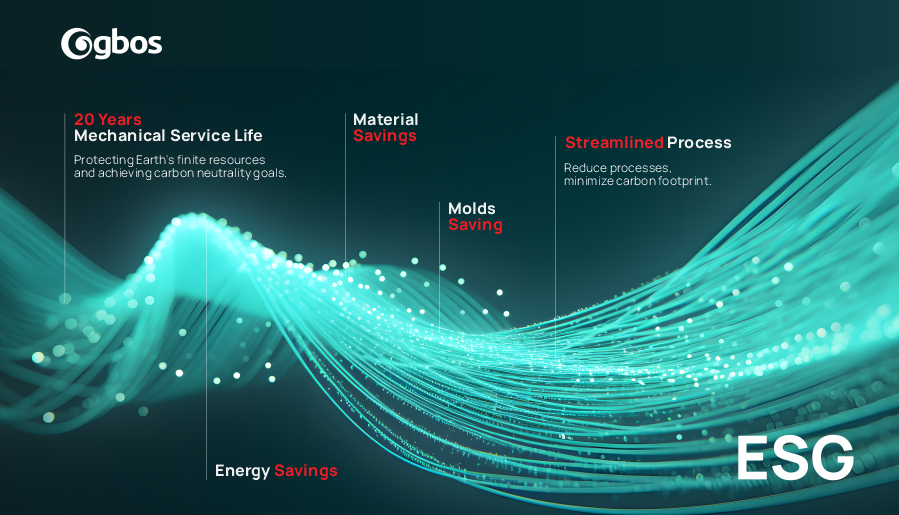

At the same time, GBOS remains steadfast in its commitment to Environmental, Social, and Governance (ESG) principles, integrating sustainability into its long-term strategy and daily operations. By championing eco-friendly and responsible manufacturing practices, GBOS aims to lead the industry toward a greener, more sustainable future.

Looking ahead, GBOS warmly invites global footwear partners and research institutions to join forces in exploring new pathways for digital transformation, leveraging the core advantages of flexible intelligent manufacturing. Through technological empowerment, GBOS strives to drive the industry toward higher-end, smarter manufacturing, ushering in a new era of innovation and excellence.

GBOS is eager to join hands with global footwear peers to create a new chapter in industry development, leading the global footwear sector toward a more exciting and prosperous future.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: