As the festive buzz of the Spring Festival fades, it leaves behind not only cherished memories of reunion but also a few extra pounds around the waist. With fitness resolutions in full swing, people are sweating it out to kickstart a healthier year.

This workout boom has undoubtedly created a surge in demand for sports lingerie, with orders rising like spring bamboo shoots. However, amidst this promising outlook, can manufacturers truly stand out?

01 The Sports Bra Market is Booming, but Manufacturers Face Growing Challenges

As health awareness deepens, exercise has become an essential part of daily life. sports lingerie, crucial for comfort and support during workouts, continue to see rising demand. Especially in the post-holiday period, a surge in fitness activities has led to an explosion in orders. However, behind this booming market, manufacturers face significant production challenges.

① Multi-Layer Material Cutting Challenges: Balancing Efficiency and Quality

Sports bras require multiple fabric layers, but cutting them poses a challenge.

Traditional methods struggle with low precision, high material waste, and slow speed, making it hard to meet demand. Cutting Lycra and seamless fabrics is especially tricky—any slight misstep can lead to uneven edges, deformation, or overcutting, impacting product quality and increasing material waste.

② Adhesive Dispensing Challenges: Quality and Production Bottlenecks

Adhesive dispensing is crucial in sports bra manufacturing, ensuring fabric layers bond securely while maintaining aesthetics and durability.

However, many dispensing machines on the market fall short, with issues like uneven glue application and inconsistent flow control. This leads to high defect rates and frequent equipment adjustments, significantly delaying production and increasing costs, putting manufacturers under immense pressure.

02 Overcoming Challenges: Exploring Effective Solutions

To address the pressing issues faced by sports bra manufacturers, we present high-quality solutions: the VC9-1616TT Premium Line Cutting Machine and the DP-GN1280TT-AT-SCCD PUR Seamless Dispensing System.

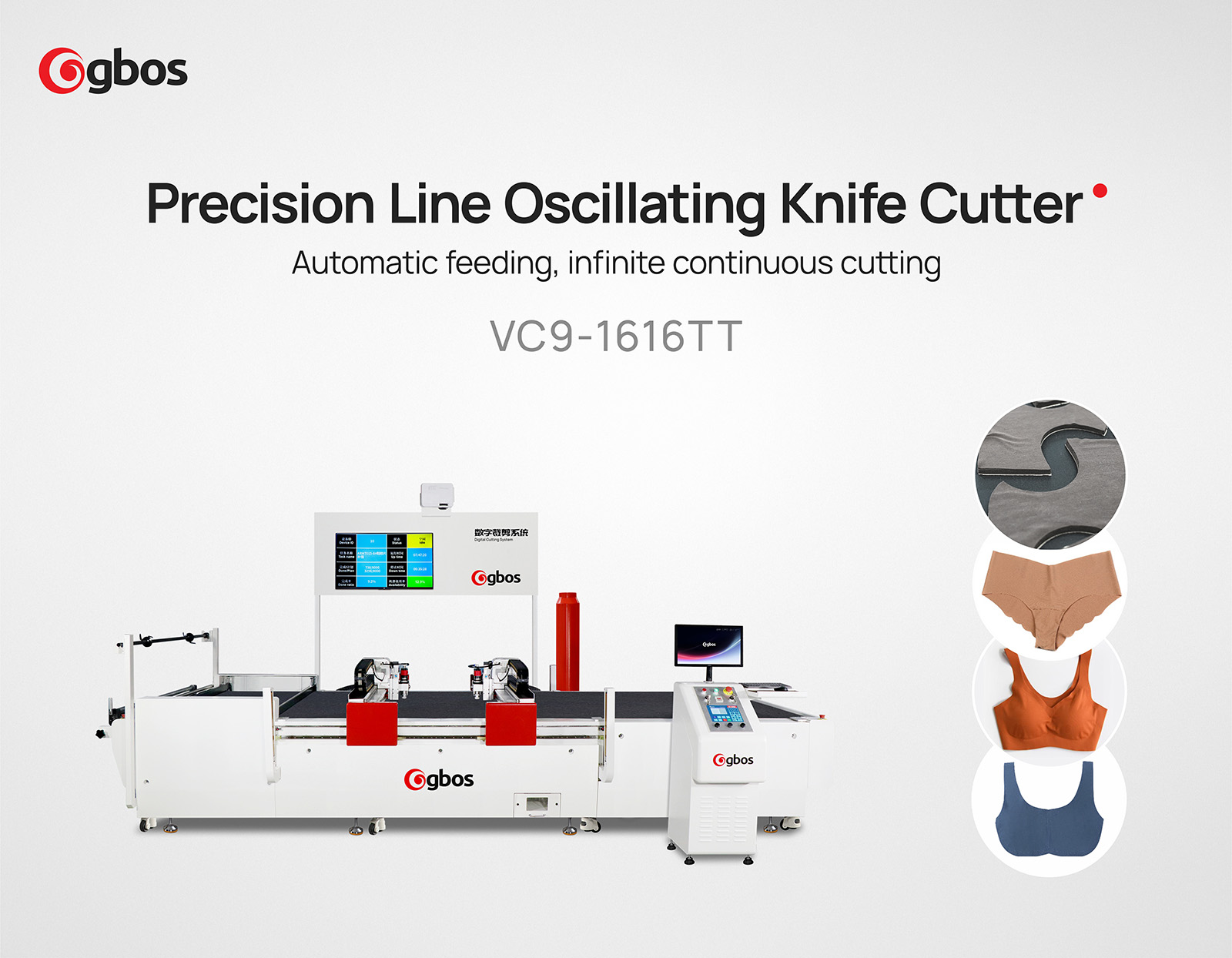

VC9-1616TT: Premium Line Cutting Machine

Equipped with a Dual-Head Asynchronous Cutting System:Dual-head coordination doubles cutting efficiency, driving a new leap in production speed.

Equipped with a Dual-Head Asynchronous Cutting System:Dual-head coordination doubles cutting efficiency, driving a new leap in production speed.

Multi-Layer Automatic Clamping & Feeding System:Fully automated workflow eliminates manual constraints, ensuring smooth and undamaged material feeding, significantly reducing waste while balancing efficiency and precision.

Integrated One-Piece Casting:The machine body is built using one-piece casting technology, ensuring long-term durability and resistance to deformation under high loads.

Projection Preview & Positioning System:Real-time preview of nesting layouts provides intuitive operation and optimizes every step of the production process.

IoT Bridge (Internet of Things):Seamlessly connects all smart workshop devices, eliminating data silos and enabling more effective production efficiency assessment and TPM (Total Productive Maintenance) management.

DP-GN1280TT-AT-SCCD: PUR Seamless Dispensing Innovative Technology

Dual-Head Asynchronous PUR Dispensing System:Precision dispensing above 98%, ensuring uniformity without stringing. Adjustable spacing and size, with dual-head parallel operation, significantly boosting production capacity.

AI Vision Recognition System:Automatically identifies piece shapes and generates templates with one click, eliminating manual positioning and greatly enhancing production efficiency and flexibility.

Simultaneous Processing of Multiple Shapes:With the support of the AI Vision Recognition System, multiple areas can be processed simultaneously, further increasing production efficiency.

From premium fabric cutting to seamless dispensing innovation, we offer a comprehensive production solution that combines efficiency and digitalization. We invite you to explore this powerful combination—it could be the secret weapon to unlocking production bottlenecks and standing out in the fierce market competition.

Join us in unlocking a broader future in the sports lingerie manufacturing industry and achieving exponential growth for your business.

Equipped with a Dual-Head Asynchronous Cutting System:Dual-head coordination doubles cutting efficiency, driving a new leap in production speed.

Equipped with a Dual-Head Asynchronous Cutting System:Dual-head coordination doubles cutting efficiency, driving a new leap in production speed.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: