The market demand for labour protective equipment, as a solid guardian of workers’ safety, continues to climb. At the same time, the state’s increasing attention to production safety and the introduction of a series of related policies have put forward more stringent requirements for the production of labour protective equipment. Therefore, how to achieve efficient, accurate and environmentally friendly production has become a key issue for labour protective equipment manufacturers.

01 Innovative practices to promote high-quality development of the industry

Aiming at this pain point in the labour protective equipment industry, GBOS launched the ‘Digital Cutting Center’ solution with his keen market insight and excellent technological innovation. The solution integrates ITS3-3012 AI intelligent leather nesting system, KC1660TT-3P digital cutting system and VC9-1616TT full-material multi-layer cutting system, which injects a strong intelligent power into the production of labour protective equipment.

ITS3-3012 AI Intelligent Leather Nesting System: With powerful algorithms and learning capabilities, it is able to automatically optimise the leather nesting method, significantly improve material utilisation and effectively reduce leather loss.

KC1660TT-3P Digital Cutting System: With precise cutting ability and excellent production efficiency, it ensures that the labour protection products can achieve double improvement in quality and production.

VC9-1616TT Full Material Cutting System: It is capable of completing multi-layer cutting of various auxiliary materials and regular materials, which further broadens the production scope and enhances the production efficiency.

02 Reduce costs and increase efficiency, help users sustainable development

Compared with other brands in the market, GBOS shows significant advantages in saving material and labour costs. Its innovative AI Intelligent Nesting System significantly improves material utilisation and effectively reduces production costs through accurate calculation and optimised layout. At the same time, the fully automated operation of the digital cutting system significantly reduces manual intervention, further improves production efficiency, and makes the production process more smooth and efficient.

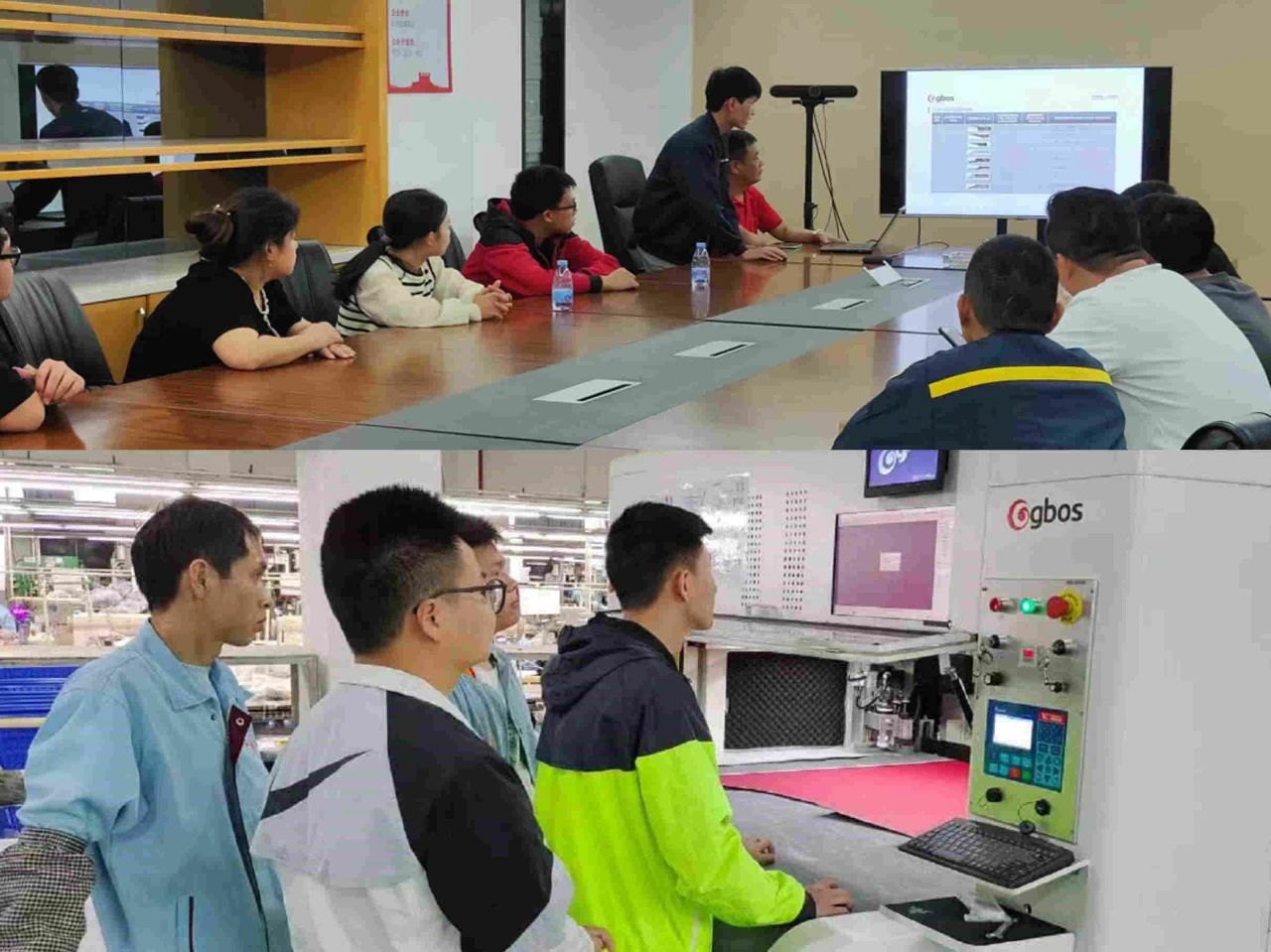

In addition, GBOS also provides a full range of after-sales services and professional training services for new machines, ensuring that customers can easily master the operation of the equipment and quickly transform the advanced solutions into actual production benefits. This not only helps customers to stand out in the fierce market competition, but also promotes the sustainable development of the enterprise.

Every technological innovation is a profound impetus to the industry. We firmly believe that through the extensive application of the ‘Digital Cutting Center’ solution, labour protection products manufacturers will be able to achieve a more efficient, accurate and environmentally friendly production mode. This will not only further improve the quality and output of products in the protection industry, but also promote the entire labour protection industry to a higher quality and higher level of development.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: