Stock Code: 870145

D Series

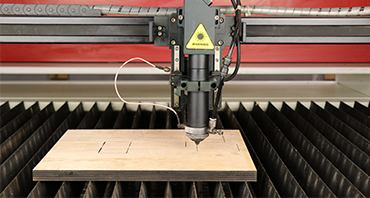

Non Metal CO2 Laser Cutting Machine for Multi-material

A classic model that has been on the market for over 15 years, it is more stable and capable of cutting both metal and non-metal materials, such as acrylic, wood, and stainless steel.

Anti-reflection device Tracking system.

Low energy consumption (start up and use).

One-stop solution for metal & non-metal materials.

Specifications

Model

Description

Industry application

Modules

Working area

Whole power

Laser power

System requirements

Power supply

Product dimensions

Weight

Custom

Product Function

-

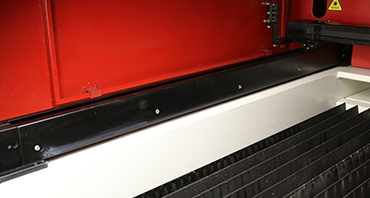

Intelligent Tracking SystemSolving the problem of deformation plate.

Intelligent Tracking SystemSolving the problem of deformation plate. -

Easy to OperateNo need to fix position, any place as starting point.

Easy to OperateNo need to fix position, any place as starting point. -

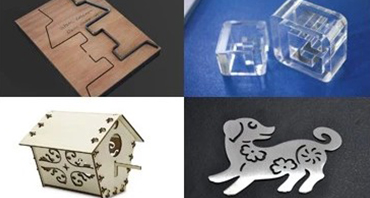

Multi-material CuttingMetal, carbon steel, wood, MDF, acrylic etc...

Multi-material CuttingMetal, carbon steel, wood, MDF, acrylic etc... -

Leading Optical Design (No Optical loss)Whole sealed, free maintainance and no laser loss design.

Leading Optical Design (No Optical loss)Whole sealed, free maintainance and no laser loss design.

Expand More +

Functions & Modules

-

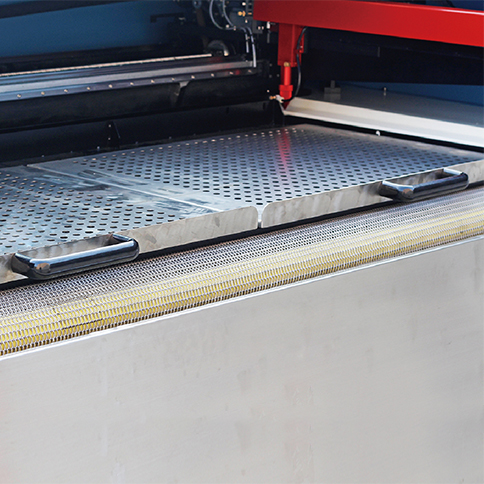

Different mesh panel materials and structures are suitable for different cutting materials and requirements.More Details

Different mesh panel materials and structures are suitable for different cutting materials and requirements.More Details -

Achieve digital management, reduce paper-oriented work, empowering “Carbon Neutral” goals.More Details

Achieve digital management, reduce paper-oriented work, empowering “Carbon Neutral” goals.More Details

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: