Stock Code: 870145

About GBOS

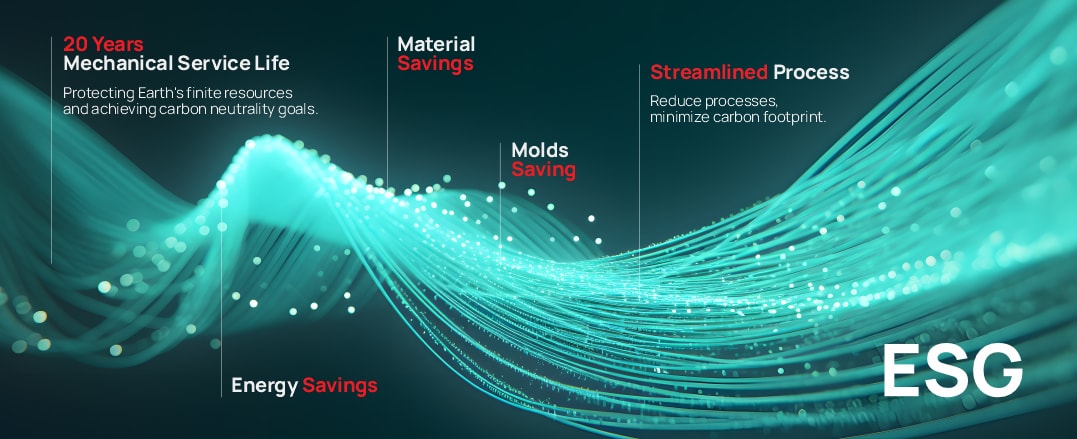

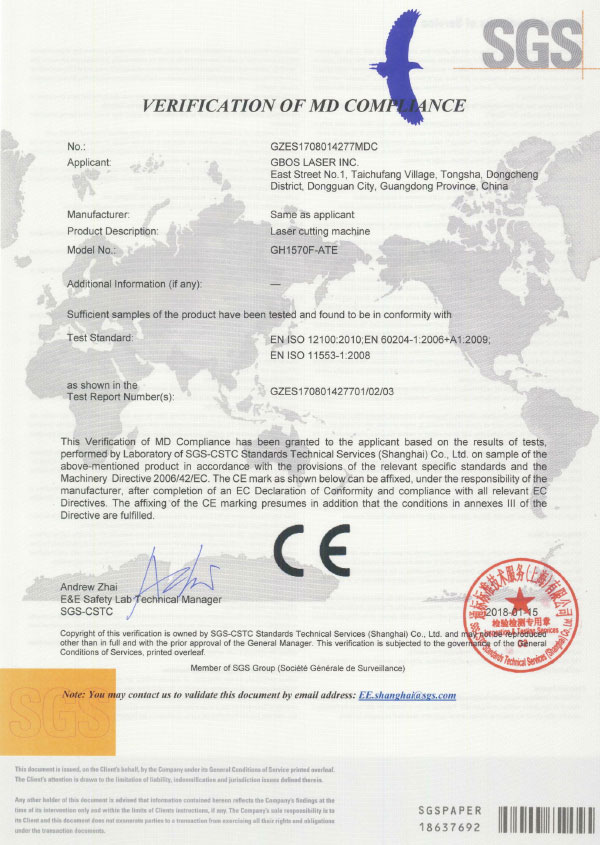

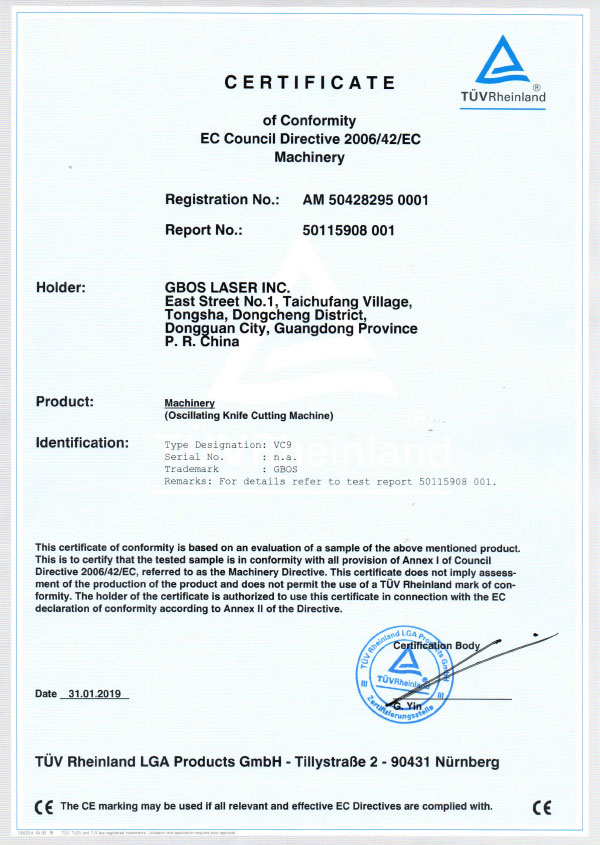

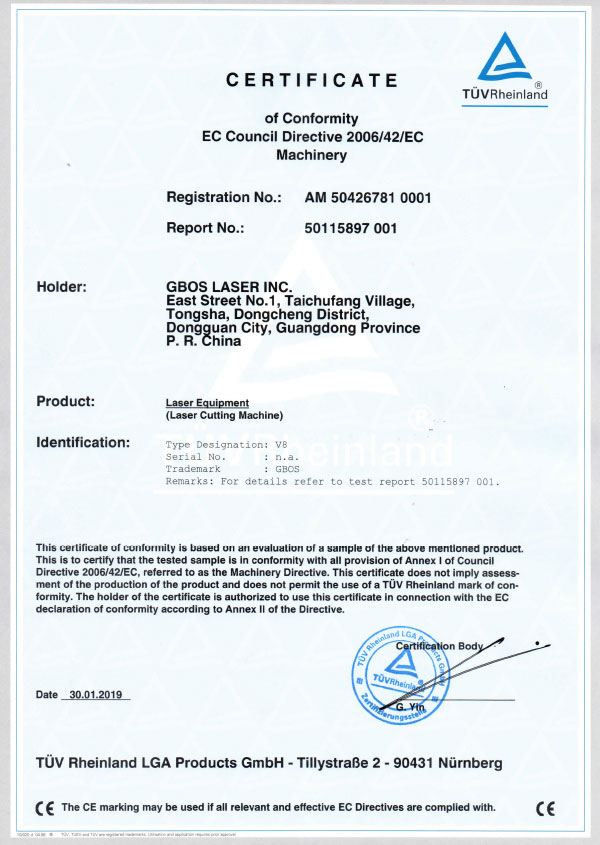

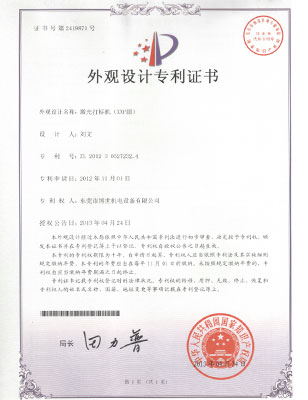

Established in Dongguan, China in 2005. GBOS LASER INC., have a production area of about 40,000 square meters. We aim to provide smart equipment solutions for global customers. Our mainly products are divided into: medium and high-end laser and oscillating knife solutions, also automatic equipment which are equipped with software and systems. GBOS has launched more than 150 intelligent equipment and products. The product range includes: laser marking, cutting and punching, laser engraving, denim jean laser process; Oscillating knife cutting, intelligent auto line marking, PUR dispensing and robotic arm applications, etc. The core technology has obtained more than 140+ patents and software copyrights, and has achieved ISO9001:2005 certification, also many series of products have obtained CE certificates of SGS & TUV. It has established more than 20 sales and service outlets in China; Branches and agency in more than 90 countries in overseas markets, supporting over 30,000 users worldwide. In 2017, we launched IoT Bridge to cooperate with users to achieve intelligent and digital transformation to enhance competitive advantage. With the mission of "To be the benchmark of equipment industry ", GBOS helps users move towards "LEAN INTELLIGENT MANUFACTURING 4.0".

190+

Patents

30+

R&D Personal

40,000㎡

Production Base

30000+

Worldwide Customers

5+

Certification Standards:

SGS/CE/ISO/FDA/BV

SGS/CE/ISO/FDA/BV

2000+

Applications Solutions

150+

Laser Systems

90+

Worldwide Clients

in 90+ Countries

in 90+ Countries

SMART LASER & KNIFE SYS

-

CO2 Laser Cutting System

CO2 Laser Cutting System -

Laser Marking System

Laser Marking System -

Oscillating Knife Digital Cutter

Oscillating Knife Digital Cutter -

Auto Line Marking Machine

Auto Line Marking Machine -

Leather Nesting System

Leather Nesting System -

Other Automation

Other Automation

Milestones

The history of GBOS is a true story of success that had its beginnings in 2005, A chronology:

Downloads

-

DownloadAbout GBOSFeb 22,2023

DownloadAbout GBOSFeb 22,2023

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: