The true refinement of automotive interiors is often hidden in the details you don’t immediately see.

From a single piece of plastic raw material to a contoured trim part that fits seamlessly into the cabin, the precision and efficiency of the cutting process directly define the upper limit of product quality—and ultimately shape a manufacturer’s core competitiveness.

01 The Dual Challenge of Cutting Complex Automotive Interior Components

As you sit inside a vehicle and run your fingers along the smooth curves of the center console or the precisely cut openings on the door panels, you probably don’t stop to think about how these complex, contoured parts are produced with such consistency. For automotive component manufacturers, however, achieving this level of precision has long been a hidden pain point in production.

Traditional stamping dies are bulky and costly to change over, making them ill-suited for customized or irregularly shaped interior parts. Manual trimming, on the other hand, relies heavily on operator experience, often resulting in inconsistent accuracy, excessive burrs, and additional finishing processes that consume time, labor, and may even compromise part precision.

As a result, the machining of complex interior parts is often trapped in a dilemma between low efficiency and inconsistent precision.

02 A Step-Change Solution: 3D Five-Axis Intelligent Cutting Technology

True gains in efficiency often come from simplifying complexity at its core.

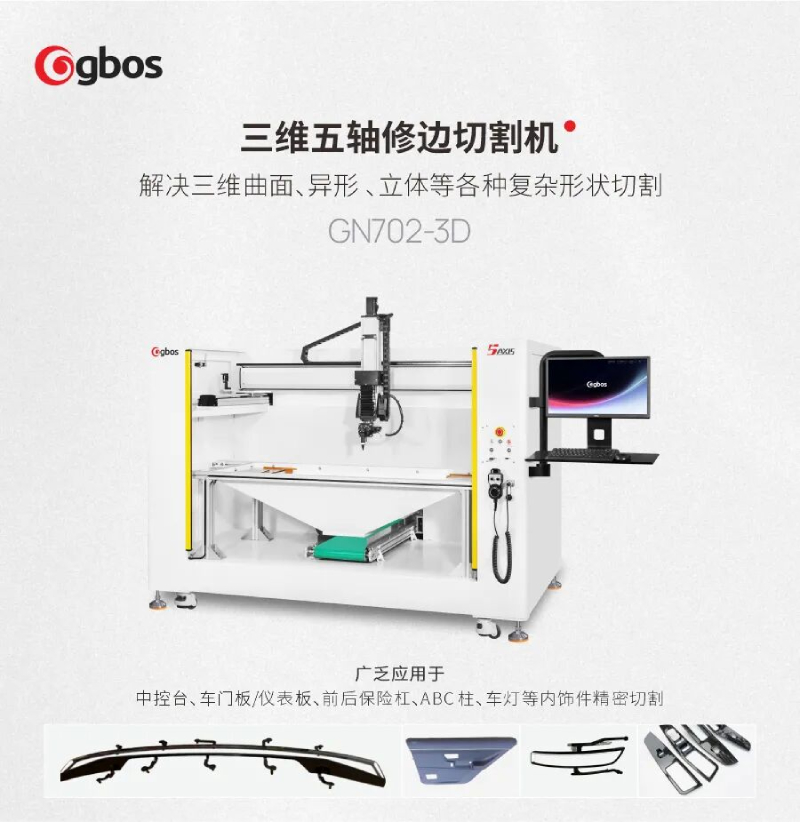

The GBOS GN702-3D 3D five-axis trimming and cutting system acts like a precision ‘spatial manipulator,’ purpose-built to solve the most demanding challenges in complex part processing.

At its core, complex part cutting requires the machine to maintain full, unrestricted contact with the workpiece—much like a surgeon relying on flexible joints to operate with precision. The GN702-3D achieves this through its 3D five-axis system, where the U-axis enables unlimited 360° rotation and the W-axis provides ±180° articulation. Working in coordination, these axes allow the cutting head to precisely follow the contours of center consoles, A/B/C pillars, headlamp housings, and other complex automotive components.

Custom-developed CAM software further removes programming barriers by automatically generating optimized tool paths—much like an intelligent navigation system—enabling one-click operation without manual coding. Combined with a linear guideway and servo-driven transmission system, the GN702-3D delivers positioning accuracy of ±0.05 mm (approximately half the diameter of a human hair), resulting in smooth, burr-free cut edges and eliminating the need for secondary polishing.

By replacing traditional stamping processes and manual trimming, the GN702-3D eliminates high tooling investments while significantly reducing labor and rework costs—delivering an optimal balance of precision, efficiency, and cost-effectiveness.

03 Value-Added Empowerment: Deep Customization as a Differentiation Advantage

In manufacturing, competition ultimately comes down to differentiation capability.

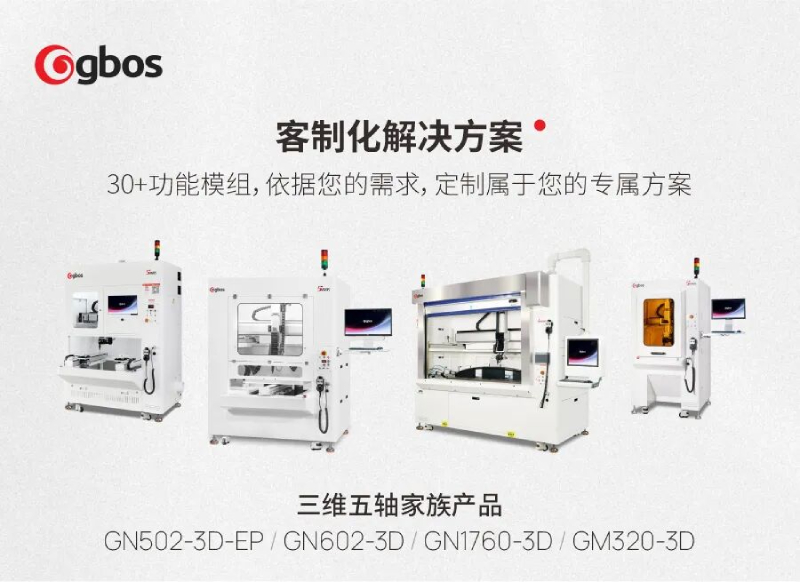

In response to the automotive industry’s rapidly evolving demands, specialized material processing requirements, and stringent quality standards, GBOS goes beyond standardized equipment by delivering deeply customized solutions.

By tailoring machine configurations to each customer’s specific production scenarios and material characteristics, GBOS enables rapid adaptation to market changes—helping manufacturers create differentiated products and gain an early advantage in the competitive automotive components sector.

Progress in manufacturing is never driven by disruptive slogans, but by turning what once seemed impossible into standardized, reliable processes. Those who master the details and align precisely with real production needs are the ones who truly shape the industry.

GBOS is committed to transforming automotive interior cutting from labor-intensive, experience-driven processes into intelligent, efficiency-driven production. By empowering every interior component through technology, GBOS turns refinement into measurable detail and embeds competitiveness directly into manufacturing processes—becoming a key driver of long-term competitive advantage for automotive manufacturers.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: