As temperatures drop, the seasonal demand for footwear rises. Leather shoes and boots—valued for their warmth and versatile texture—have become essential staples for autumn and winter outfits.

No matter whether it’s business commuting, casual daily wear, or the functional needs of outdoor activities, premium leather shoes and boots adapt effortlessly to every scenario.

Consumers’ expectations for footwear have evolved into a unified demand for style, comfort, and durability. They seek refined design while valuing material quality and overall wearing experience. This shift is accelerating the footwear industry’s move toward high-quality, precision manufacturing—opening significant market opportunities for advanced production equipment.

01 Shoe Manufacturing Faces the Pressure of Quality and Capacity Demands

With autumn and winter orders surging, footwear manufacturers are facing multiple production challenges.In terms of efficiency,

In terms of efficiency, traditional cutting equipment struggles to handle the mass processing of multiple components—such as leather shoe uppers and boot linings—making tight delivery schedules even more challenging.

On the cost side, leather prices remain high, while manual nesting and cutting result in a high waste rate—further squeezing profit margins.

On the quality side, inconsistencies in cutting accuracy across different production batches can lead to issues such as shape deviation and poor component alignment—ultimately affecting the consumer’s wearing experience.

At the same time, growing demand for personalized footwear and an increase in small-batch, multi-style orders make it difficult for traditional production methods to respond quickly.

02 Intelligent Cutting: The “Perfect Partner” to Overcome Footwear Manufacturing Challenges

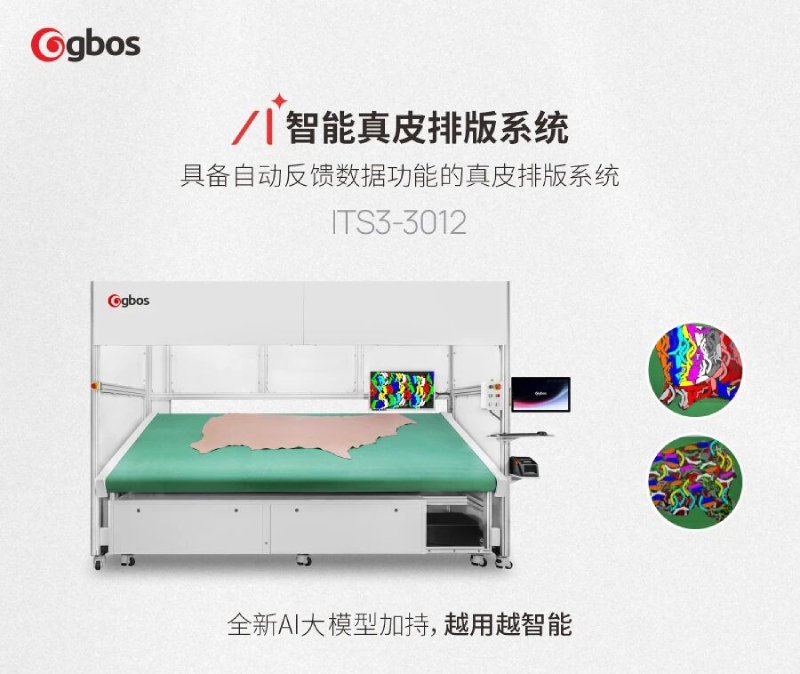

The GBOS ITS3-3012 AI Intelligent Leather Nesting System, paired with the KC1630TT-RT-3P dual-head asynchronous oscillating knife cutter, is precisely tailored to meet the production needs of leather shoes and boots.

Equipped with GBOS’s latest AI model, the ITS3-3012 intelligently detects leather defects and optimizes nesting—eliminating the need for manual selection or adjustment of flaws and contours. The more it’s used, the more efficient it becomes, reducing material waste right from the source.

The KC1630TT-RT-3P, a versatile cutting specialist, effortlessly handles various footwear materials—including genuine leather, synthetic leather, and accessories—making it suitable for processing uppers, linings, and other shoe components.

The dual-head asynchronous operation mode significantly boosts cutting efficiency. Paired with a punching dust extraction system, debris generated during punching is automatically collected into a waste bin, keeping the workspace over 90% clean.

High-precision cutting technology ensures consistent dimensions for footwear components in mass production. It also supports “knife-eating” techniques to accommodate stitching requirements, improving material utilization and achieving tighter joins—helping manufacturers balance quality and delivery efficiency while confidently meeting peak autumn and winter orders.

03 Empowered by Technology: Advancing the Footwear Industry Toward a New Era of Quality

Advancements in footwear reflect the industry’s dual pursuit of efficiency and quality. GBOS leverages AI nesting and high-efficiency cutting technologies to address key production challenges, ensuring every pair of leather shoes and boots combines exquisite craftsmanship with consistent quality.

Looking ahead, as consumer demands continue to evolve, GBOS will keep focusing on the footwear industry—providing smarter, more efficient production equipment to help manufacturers advance steadily on the quality track and deliver a superior footwear experience to consumers.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: