On social media, curious consumption scenes often appear:A lady flaunts her Hermès Birkin bag to showcase luxury, yet orders no-name tissues online; an outdoor enthusiast wears an Arc’teryx hardshell jacket, but charges their phone with a 9.9-yuan data cable.

At first glance, this seems contradictory—but it reflects a rising trend: brand value separation.

1. Why Is Brand Value Starting to Separate?

The core driver of this trend is the demystification and openness of supply chains.

In the past, consumers had little knowledge about which factory produced a certain pair of jeans or which supplier crafted the leather for luxury shoes. Today, however, supply chain transparency has transformed what used to be “exclusive formulas” into “public recipes” that are easily accessible.

This shift erodes the monopoly of tangible brand value. When products can be replicated quickly, consumers no longer pay premiums for material exclusivity alone.

But does this mean brands are destined to fail? Absolutely not.Instead, it eliminates the bubble and pushes brands back to the essence of value creation—building deeper, harder-to-replicate barriers.

2. How Can Brands Rebuild Value Barriers?

The most direct approach is to excel in tangible value, creating technological barriers that ensure:

What others don’t have, we provide.

What others have, we do better.

In this way, consumers are no longer just paying for a logo—they’re paying for genuine, irreplaceable performance advantages.

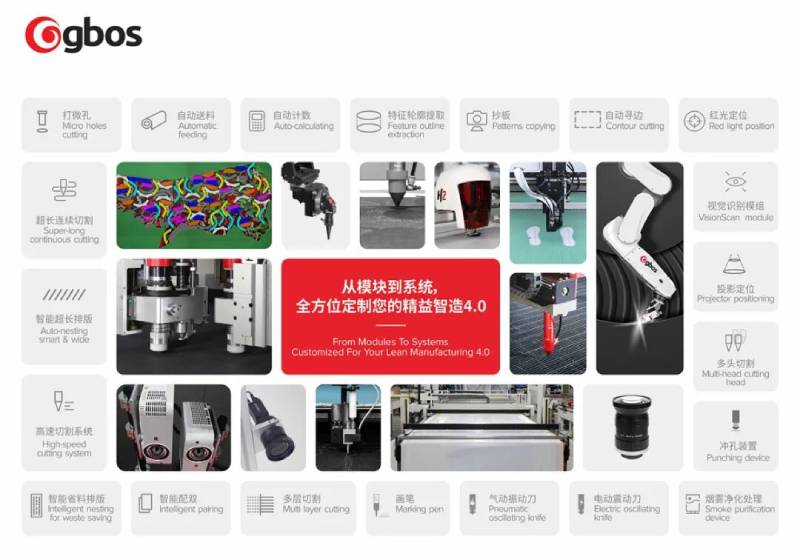

GBOS as an Example:GBOS has long been committed to innovative intelligent manufacturing, continuously pushing the boundaries of the industry and empowering brand partners with higher value.

From the precise and efficient Digital Cutting System to pioneering Laser Equipment; from highly flexible Customized Automation Solutions to the trend-leading S-Denim 6.0 Denim Washing Solution; from the intelligent GBOS Deep Large Model to the latest IoT Bridge System—every breakthrough reflects the expertise of GBOS, representing the cutting edge of the industry.

These technologies not only serve as GBOS’s “hard business card,” but also empower partner brands with a triple competitive advantage:

Cost reduction;

Efficiency improvement;

Quality enhancement.

While many competitors still struggle with low efficiency and poor yield, GBOS partners capture markets with superior processes and higher-quality products, forging a strong foundation for differentiated brand competitiveness.

3. Continuous Innovation: The Key to Long-Term Brand Value

Brand barriers are never static. They must be continuously reinforced through ongoing innovation.

In the past, a brand was a lofty symbol of identity. Today, its long-term value depends on its ability to “continuously create value.” This is precisely the principle GBOS upholds—anchored in research and development, user-centered, and always refreshing brand value.

In the wave of brand value separation, no brand can stand alone. GBOS, through technological innovation and full-chain empowerment, helps its partners withstand the impact of substitutes, define unique brand positions, and move toward a future built on efficiency, sustainability, and high value.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: