As the Mid-Autumn Festival approaches, mooncake manufacturers are once again preparing for a surge in orders. This festive season brings not only a rise in production but also stronger demand for refined craftsmanship in mooncake gift box packaging.

Breaking Boundaries in the Packaging Industry

Traditional mooncake packaging faces multiple challenges. Homogenization makes it difficult for brands to stand out. It leaves little lasting impression on consumers. Environmental shortcomings also conflict with the global push for sustainable development. In addition, the user experience remains relatively flat, often limited to the outer shell of the box.

Today, sustainable production has become a prevailing trend. Consumers’ demand for eco-friendly food packaging is reshaping the entire supply chain. From material selection to production processes, standards of low energy consumption, minimal waste, and recyclability have become essential benchmarks in the international market.

Smart Manufacturing: Empowering the Packaging Industry

Mooncake gift box production must deliver aesthetic appeal and functionality. At the same time, it needs to align with the global consensus on green manufacturing. GBOS brings eco-conscious DNA into the packaging industry through digital innovation. This allows manufacturers to strike a balance between efficiency and sustainability.

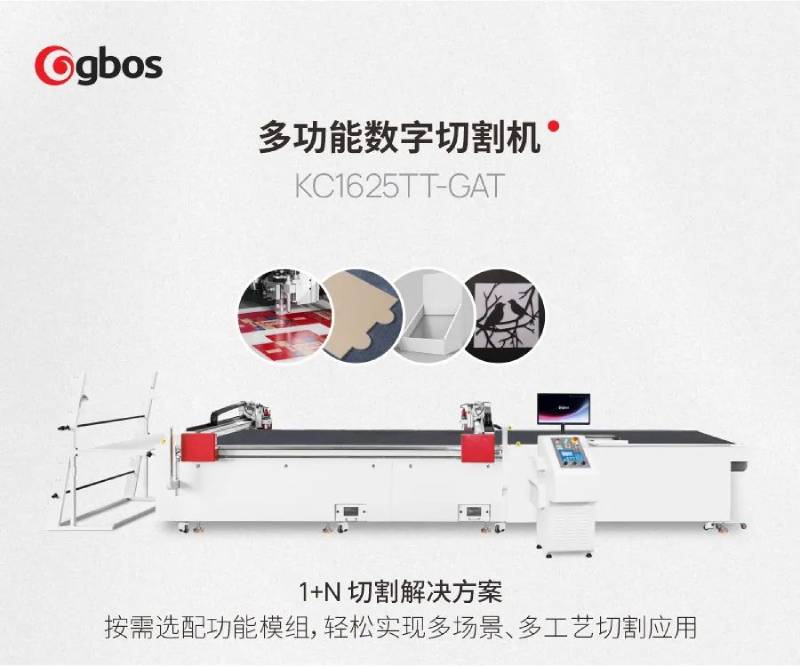

The multifunctional KC1625TT-GAT digital cutter injects new vitality into packaging production. Equipped with an oscillating knife, it can cut a wide range of materials with precision. Cardboard, corrugated board, and biodegradable alternatives can all be processed with clean edges and no fraying. This precision enhances the appearance and perceived value of the packaging.

Its creasing device adds clear and uniform fold lines. This makes box assembly smoother, faster, and more accurate. It also improves the structural integrity of the finished packaging. The optional SCCD visual recognition system acts as a powerful upgrade. It quickly and precisely identifies printed patterns and markings. As a result, cutting and creasing are more accurate, material waste is reduced, and production costs are lowered.

Combining Tradition with Efficiency

Mooncake packaging is more than just a protective layer. It carries culture, tradition, and emotion. By integrating digital cutting technology, the KC1625TT-GAT addresses the efficiency and accuracy issues of traditional production. At the same time, it embeds sustainability into every stage of the process.

When mechanical precision meets cultural warmth, the result is powerful. Packaging not only satisfies consumers’ pursuit of beauty but also responds to global expectations for sustainability. This is the true essence of technological empowerment: making production more efficient, traditions more enduring, and the future greener.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: