From the meticulously hand-stitched traditional cloth shoes to the mass-produced athletic footwear churned out by assembly lines, the footwear industry has undergone centuries of evolution and transformation. As the pace of industrialization quickens, cost control has emerged as the linchpin of corporate competition, fueling the prevalence of large-scale standardized production.

New directions under the changing needs of the times

In the early days, consumers’ demand for shoes was mainly focused on meeting daily wear, and footwear enterprises pursued production volume to satisfy the huge market demand.

Today, consumer demands have become increasingly diversified and personalized. People are no longer satisfied with the basic functions of shoes alone, but have higher requirements for design and environmental protection. This series of demand changes has prompted the footwear industry to continuously explore new development directions.

The Imminent Challenges Facing Manufacturers

In the transformation of footwear products from “output priority” to “cost control” and now to the era where “production capacity, cost, innovation, and environmental protection go hand in hand”, footwear enterprises are faced with numerous challenges.

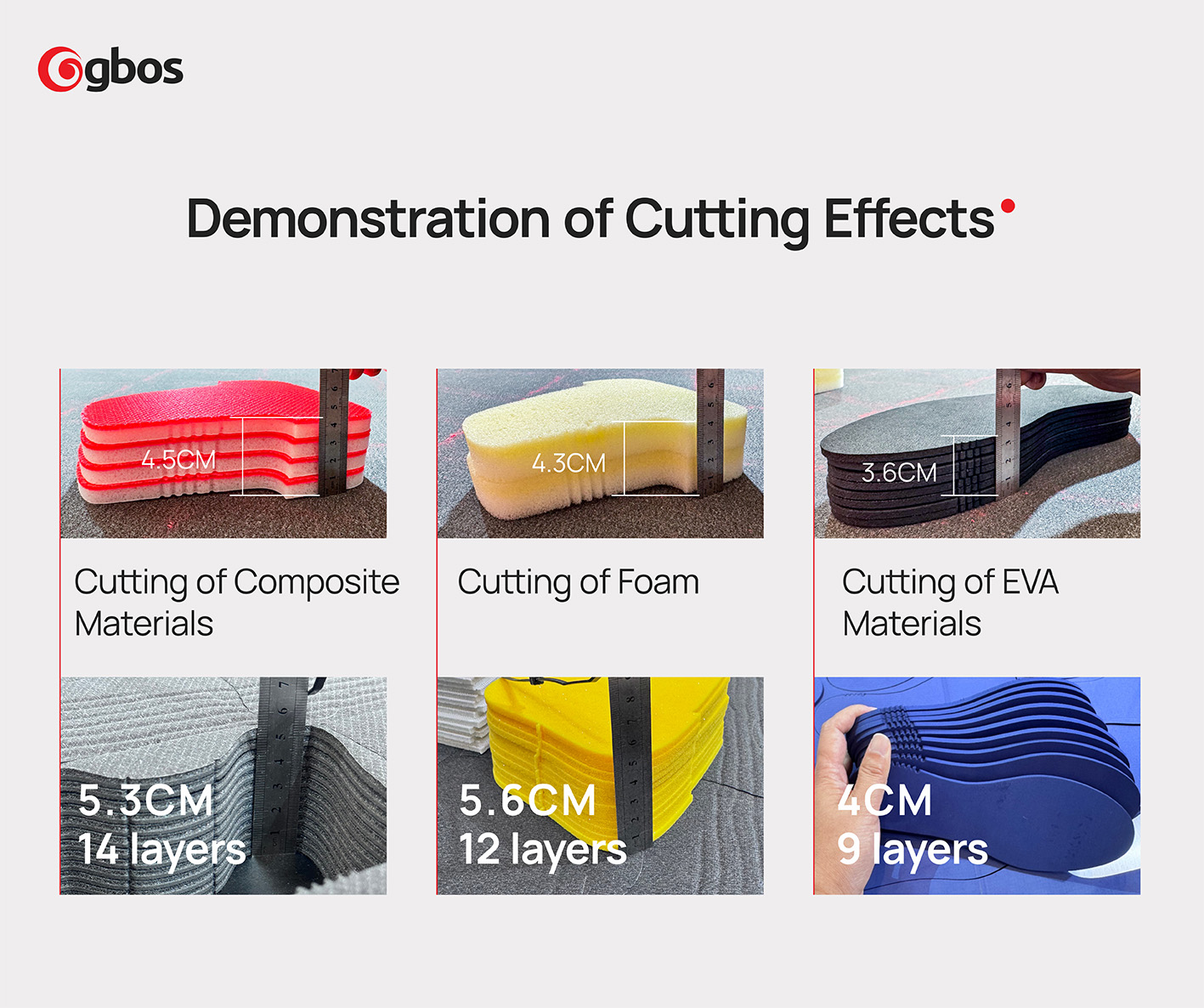

Traditional production equipment and processes struggle to meet complex and diverse design requirements. When handling multi-layer foams and composite materials, low cutting precision and poor efficiency lead to severe material waste, thereby increasing production costs.

How to enhance production efficiency and reduce costs while ensuring product quality has become an urgent issue for footwear enterprises to solve.

The Rising Stars in the Thriving Footwear Industry

To meet these demands, the GBOS team has developed a range of star products for the footwear industry. Among them, the new multi-functional high-layer fine digital cutting bed H3-T serves as a cutting-edge solution specifically designed to address the challenges of processing multi-layer foams and composite materials in the production process.

In terms of technological innovation, the H3 – T replaces traditional felt with “bristled bricks”. Coupled with a high – suction bed – passing device, it effectively solves the problem of unstable feeding of high – layer foam materials.

Meanwhile, its production capacity reaches 7,000 – 15,000 pieces per hour, significantly enhancing production efficiency and saving enterprises substantial time and labor costs.

The precise cutting technology of H3 – T not only reduces material waste, but also enables the perfect realization of complex designs. It meets enterprises’ need for the rapid delivery of large – volume orders, helping them gain a head start in the new development of the footwear industry.

Experience the Charm of Intelligent Manufacturing at Close Range

GBOS is committed to enabling footwear enterprises to stand out in the fierce market competition and promoting the footwear industry to develop towards intelligence,efficiency and greenness.

From May 28th to 30th, 2025, the H3-T will make another appearance at the Guangdong International Intelligent Shoe Machinery and Equipment Exhibition. During this exhibition, a brand-new product integrating “typesetting + coding + cutting” will also be released.

We sincerely invite you to visit the exhibition site, experience the cutting-edge technology up close, explore the new future of intelligent footwear manufacturing with GBOS, and unlock more development possibilities together.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: